Branch shear

A branch and scissors technology, applied in the field of branch scissors, achieves the effects of exquisite design, low transformation difficulty and easy use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

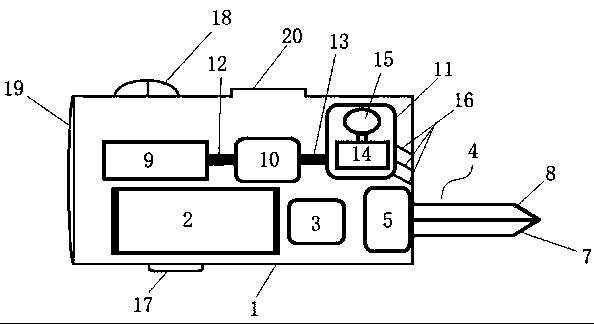

[0022] The present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

[0023] A kind of branch shears, described branch shears comprises fuselage shell 1, power supply 2, motor 3, scissors head 4, scissors head driving device 5, and described scissors head 4 comprises fixed blade 7 and movable blade 8; Said power supply 2 , the motor 3, the scissor head 4, and the scissor head driving device 5 are all arranged in the body shell 1, and also include a control circuit system, the control circuit system makes the power supply 2 connected to the motor 3, and the motor 3 is connected to the motor 3 The scissor head driving device 5 is connected, and the scissor head driving device 5 is connected with the moving blade 7 of the scissor head 4; it also includes a disinfection device, which is arranged in the body shell 1, and the disinfection device includes Ozone electrolysis generator group 9, ozone mixing device 10, spray...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com