Manufacturing method of copper-iron-based diamond cutter teeth

A manufacturing method and diamond technology, applied in the field of diamond cutter teeth, can solve the problems of poor drilling effect, short service life, poor wear resistance, etc., and achieve the purpose of suppressing the loss of low melting point metals, long service life and good wear resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0009] A method for manufacturing a copper-iron-based diamond cutter tooth, comprising the following steps: preparing a carcass material with a skeleton material and a bonding metal, mixing the materials after the preparation, loading the materials after the mixing is completed, and performing hot pressing molding, and Cooling and mechanical processing after cooling, wherein the powder in the matrix material preparation process includes Cu40%, Fe30%, Sn8%, Ni 12% and WC10%, and the weight added during the mixing process is the total weight of the matrix material. 7% diamond by weight, the diamond adopts 30% 35 / 40 mesh diamond, 40% 40 / 45 mesh diamond and 30% 45 / 50 mesh diamond.

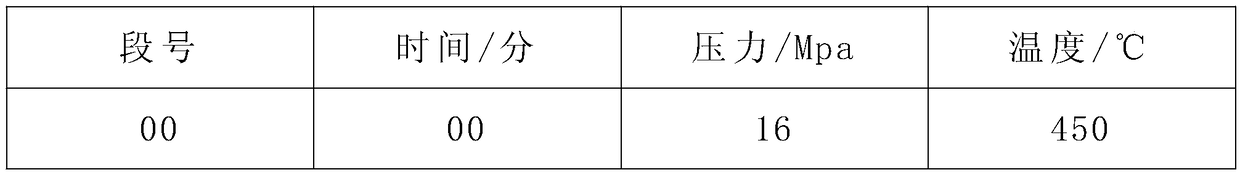

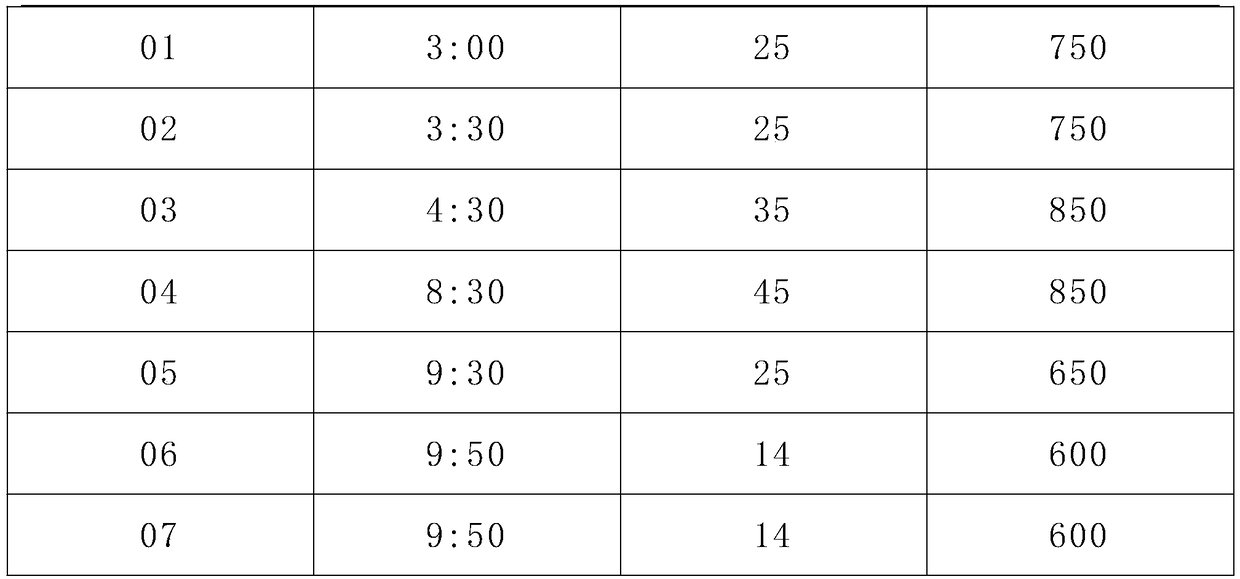

[0010] Among them, the time, temperature and pressure controlled during hot pressing are shown in the table below;

[0011]

[0012]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com