Method for preparing graphene reinforced magnesium-based composite material based on powder thixoforming

A technology of thixotropic deformation and composite materials, which is applied in the field of preparation of graphene-reinforced magnesium-based composite materials, can solve problems such as low density, poor graphene dispersion, and complex shapes, and achieve high density, simple process, and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

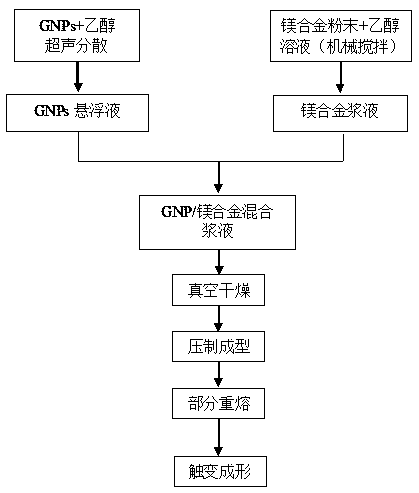

[0034] The process of preparing graphene-reinforced magnesium-based composite material based on thixotropic deformation of the present embodiment is carried out in the following steps:

[0035](1) Add 0.5g of graphene nanosheets with a sheet thickness of 3-10nm and a radial size of 5-10μm into 500ml of absolute ethanol, and use an ultrasonic processor to sonicate for 60min to obtain a graphene ethanol suspension; Atomized spherical ZK61 magnesium alloy powder for -325 mesh was added to 100ml ethanol solution, and graphene ethanol suspension was slowly added dropwise to the ethanol slurry of ZK61 magnesium alloy powder while mechanically stirring to obtain GNP / ZK61 mixed slurry. After mechanically stirring for 120 minutes in a constant temperature water bath at 30°C, the mixed slurry was in a paste state, and the stirring speed was 500 r / min.

[0036] (2) Filter the GNP / ZK61 mixed slurry obtained in step (1), remove the ethanol solution, and then put it in a vacuum drying oven ...

Embodiment 2

[0042] The difference between this embodiment and Example 1 is that the remelting temperature in step (4) is increased to 635°C. Repeat the steps (1), (2) and (3) in Example 1 to obtain the GNP / ZK61 cold-pressed blank; raise the partial remelting temperature of the GNP / ZK61 compact to 635°C, and the remelting time is still 60min. Repeat the step (5) in Example 1 to obtain GNP / ZK61 semi-solid ingot; keep the mold temperature, pressure and pressure holding time in Example 1 unchanged, and obtain GNP / ZK61 magnesium-based composite after thixoforming Material.

Embodiment 3

[0044] The difference between this embodiment and Example 1 or 2 is that the remelting temperature in step (4) is lowered to 620° C., and the others are the same as Example 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com