Sludge blending and conveying system and method of supercritical water oxidation treatment system

A supercritical water oxidation and treatment system technology, applied in the oxidation treatment of sludge, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problems of low thermal conductivity, poor fluidity, and difficulty in realizing continuous transportation, etc. To achieve the effect of enhancing heat transfer and heating capacity, reducing flow resistance, improving efficiency and energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

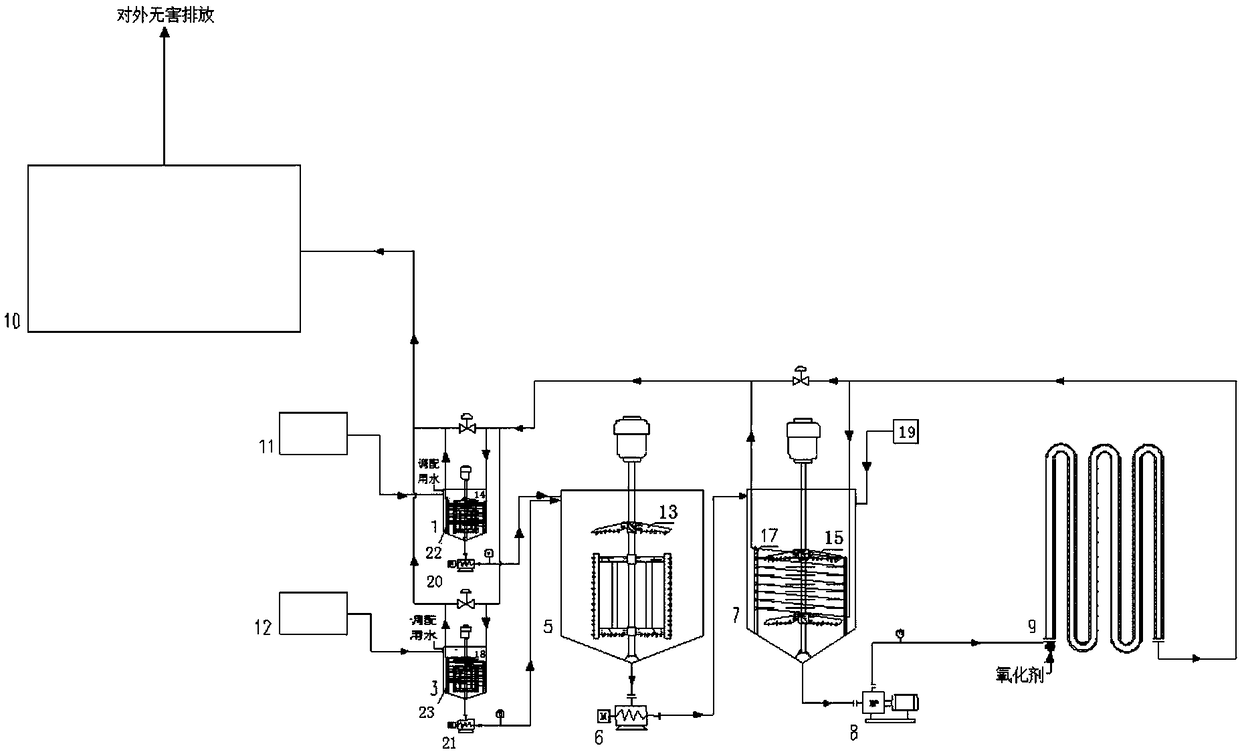

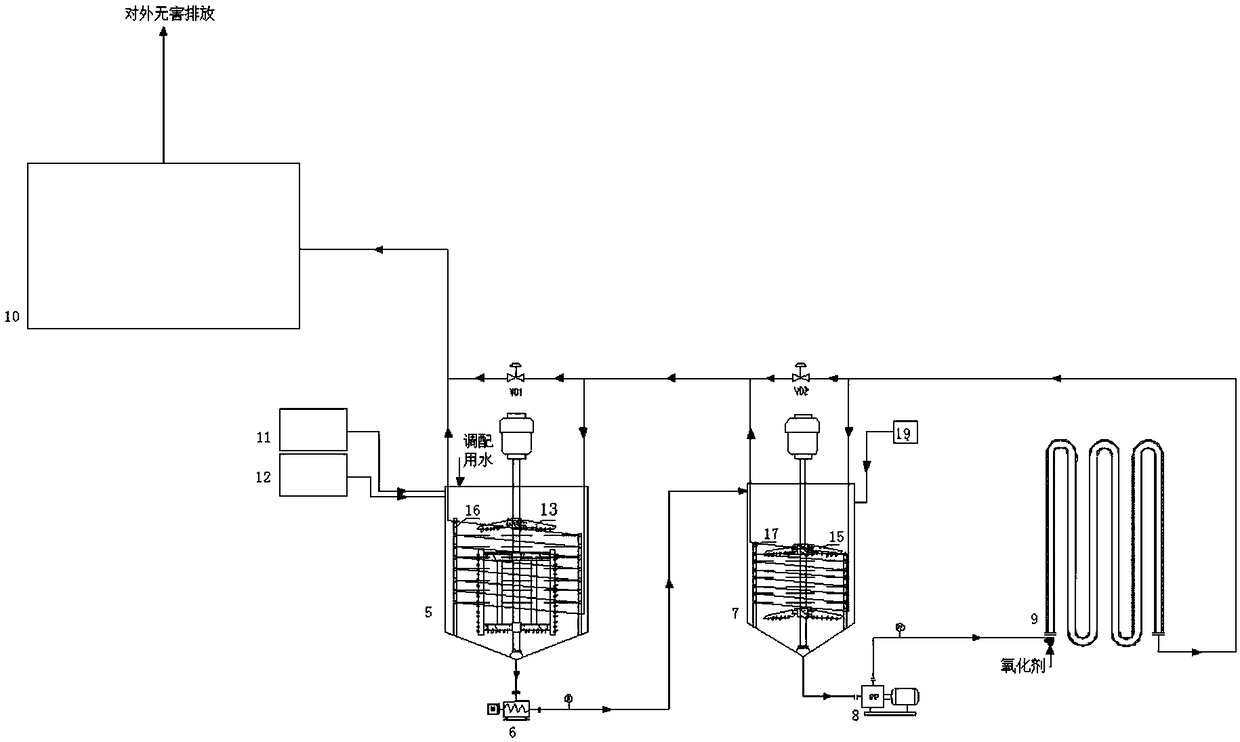

[0035] see figure 2 , the second embodiment of the present invention is the same as the first embodiment except for the first heating and mixing system. In this embodiment, the first heating and mixing system includes two material allocation heating and mixing devices, a material buffer pool 5 and a first mixer 13 arranged inside the material buffer pool 5; the outlet of the material allocation heating and mixing device is sequentially connected to the material buffer pool 5 and the second Two heating mixing systems. A material blending heating and mixing device includes a first material blending pool 1, a second screw pump 20, a second mixer 14 arranged inside the first material blending pool 1 and a third high temperature and high pressure exchanger arranged inside the first material blending pool 1 The heater 22 ; the outlet of the first material adjustment tank 1 is connected to the second screw pump 20 and the material buffer tank 5 in sequence. Another material blendi...

Embodiment 1

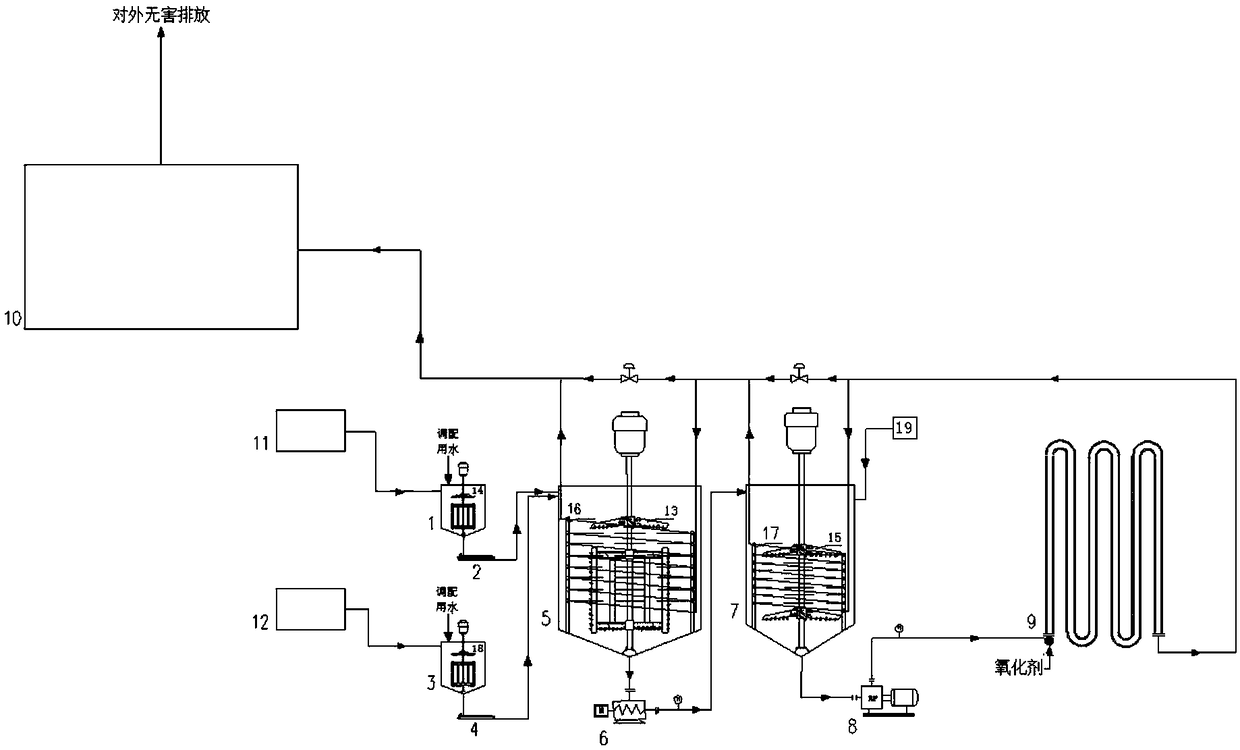

[0045] see figure 1 , the first material storage tank 11 and the second material storage tank 12 transport the sludge to the first material allocation pool 1 and the second material allocation pool 3 respectively, and inject water for allocation at the same time; Under the action of the second agitator 14 and the fourth agitator 18 in the material blending pool 1 and the second material blending pool 3, the mixing and homogenization are preliminarily completed, and the first material blending pool 1 and the second material blending pool 3 can be used to store the prepared Sludge; then the sludge is strongly transported to the material buffer tank 5 by the first material conveyor 2 and the second material conveyor 4, and the single-strand sludge feeding or double-strand sludge mixed feeding can be determined according to the actual situation; the sludge Under the action of the first mixer 13, multi-dimensional and complex shearing operation is carried out to further complete th...

Embodiment 2

[0048] see figure 2 , the first material storage tank 11 and the second material storage tank 12 transport the sludge to the first material allocation pool 1 and the second material allocation pool 3 respectively, and inject water for allocation at the same time; Under the action of the second agitator 14 and the fourth agitator 18 in the first material blending pool 1 and the second material blending pool 3, the mixing and homogenization are preliminarily completed; at the same time, through the third high temperature and high pressure heat exchanger 22 and the fourth high temperature and high pressure heat exchanger The wall surface of the heat exchange tube at 23 absorbs heat and heats up to no less than 70°C; then the sludge is forcefully transported to the material buffer pool 5 through the second screw pump 20 and the third screw pump 21, and the material buffer pool 5 is used for storage, buffering, deployment and heating The final sludge acts as a buffer when the proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com