Water-based environment-friendly coating and preparation method thereof

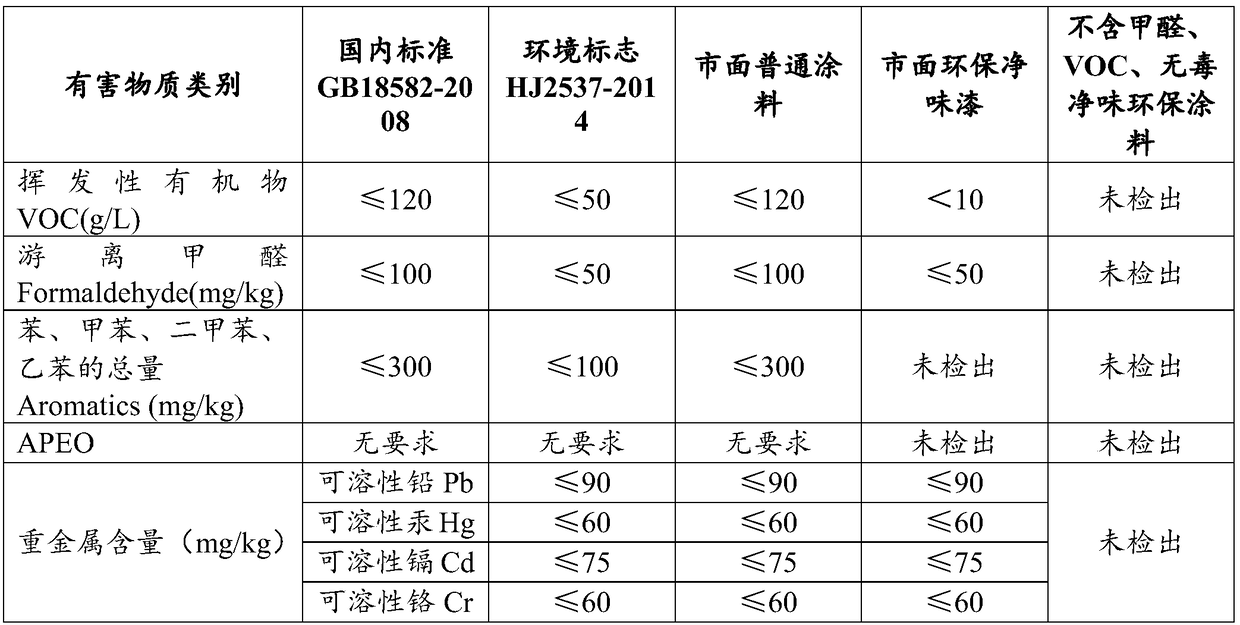

An environmentally friendly paint, water-based technology, applied in the field of paint, can solve the problems of health and environmental hazards, the inability to detect heavy metals, etc., and achieve the effects of good dispersibility and stability, excellent scrub resistance, and good dispersibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] Correspondingly, the embodiment of the present invention also provides a preparation method of the above-mentioned water-based environmental protection paint. Described preparation method comprises the steps:

[0034] S01. Measure each ingredient raw material respectively according to the ingredients and their content in the water-based environmental protection paint mentioned above;

[0035] S02. Mix water, dispersant, wetting agent, and defoamer to prepare the first mixed solution;

[0036] S03. Adding weighed titanium dioxide, kaolin, diatomaceous earth, and calcium carbonate to the first mixed solution to prepare a second mixed solution;

[0037] S04. Adding the weighed cellulose into the second mixed liquid for mixing treatment to prepare a slurry;

[0038] S05. Add the weighed freeze-thaw stabilizer, emulsion, defoamer, thickener, pH regulator, and bactericide to the slurry for mixing treatment, then adjust the viscosity with water and then filter.

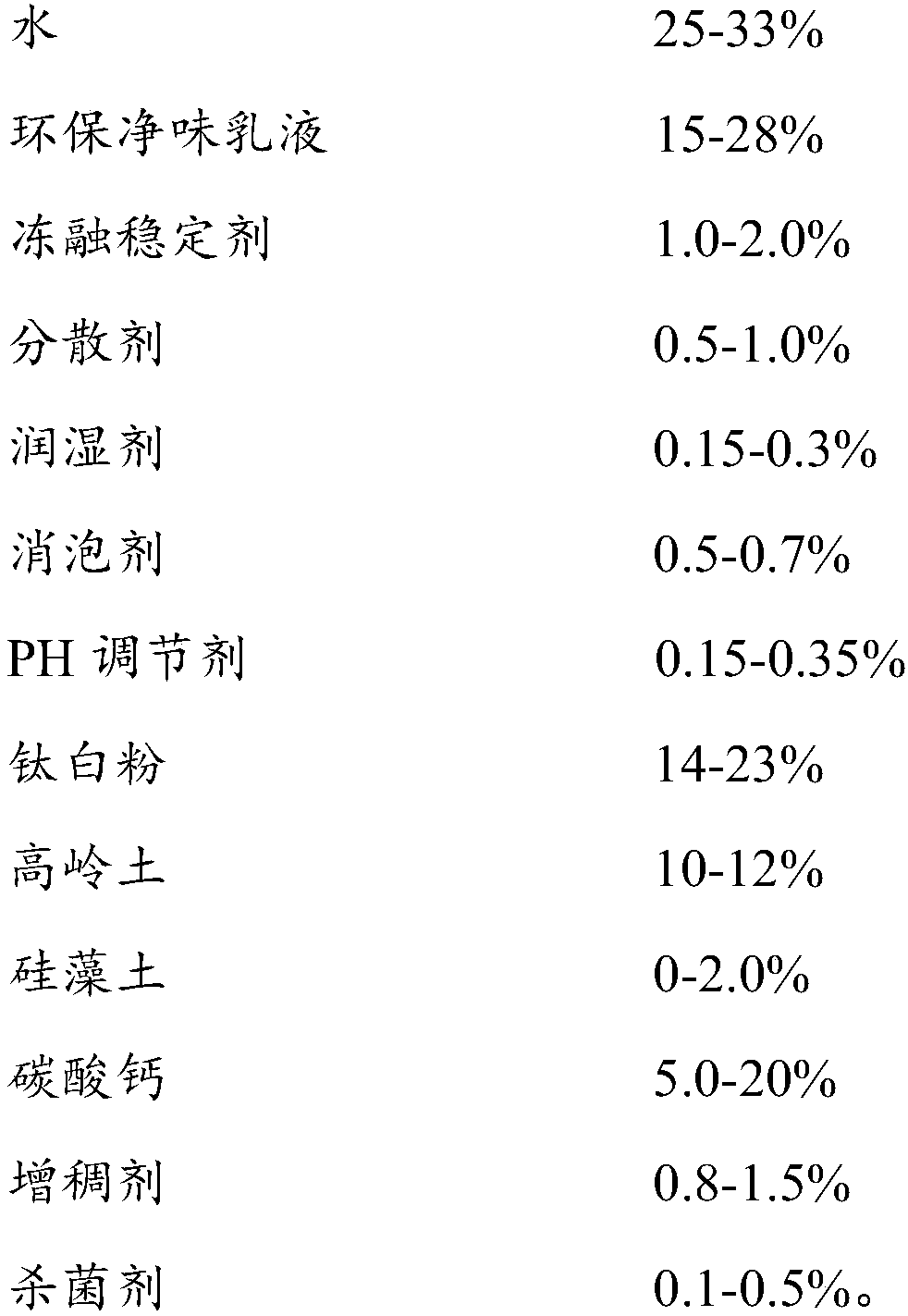

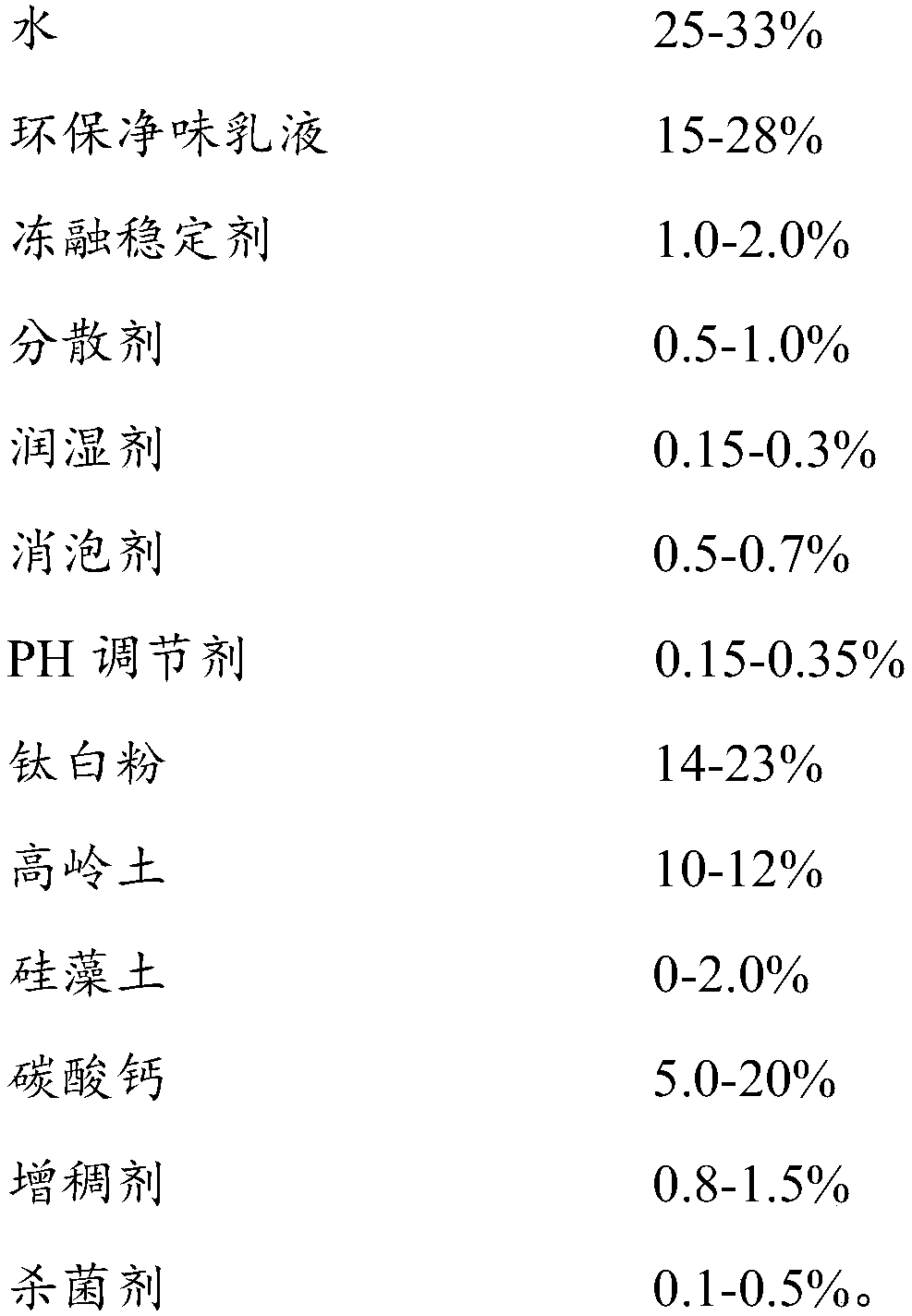

[0039] Spe...

Embodiment 1

[0049] This embodiment provides a formaldehyde-free, VOC-free, non-toxic and odor-free water-based environmentally friendly paint and a preparation method thereof. Described water-based environmental protection coating contains component (weight percent %) as shown in following table 1:

[0050] Table 1

[0051] Water: 21

Freeze-thaw stabilizer: 1.0

Dispersant: 0.5

Lotion: 15

Wetting agent: 0.15

Polyether modified silicone defoamer: 0.3

Silicone defoamer: 0.2

Hydrophobic modified polyurethane thickener: 1.0

Titanium dioxide: 14

pH regulator: 0.15

Kaolin: 12

Fungicide: 0.1

Water: 9.1

Cellulose: 0.5

Water: 5

[0052] The preparation method of the water-based environmental protection coating that does not contain formaldehyde, VOC, nontoxic and clean taste is as follows:

[0053] S11: Weigh each component according to the formula ratio described in Tabl...

Embodiment 2

[0059] This embodiment provides a formaldehyde-free, VOC-free, non-toxic and odor-free water-based environmentally friendly paint and a preparation method thereof. Described water-based environmental protection paint contains component (weight percentage %) as shown in following table 2:

[0060] Table 2

[0061] Water: 23

Freeze-thaw stabilizer: 1.5

Dispersant: 0.6

Lotion: 20

Wetting agent: 0.3

Polyether modified silicone defoamer: 0.3

Silicone defoamer: 0.3

Hydrophobic modified polyurethane thickener: 0.5

Titanium dioxide: 20

pH regulator: 0.2

Calcined kaolin: 11

Fungicide: 0.15

Calcium carbonate: 13

Water: 3.65

Cellulose: 0.5

Water: 5

[0062]The preparation method of the water-based environmental protection coating that does not contain formaldehyde, VOC, nontoxic and clean taste is as follows:

[0063] S21: Weigh each component according to the formula ratio describe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com