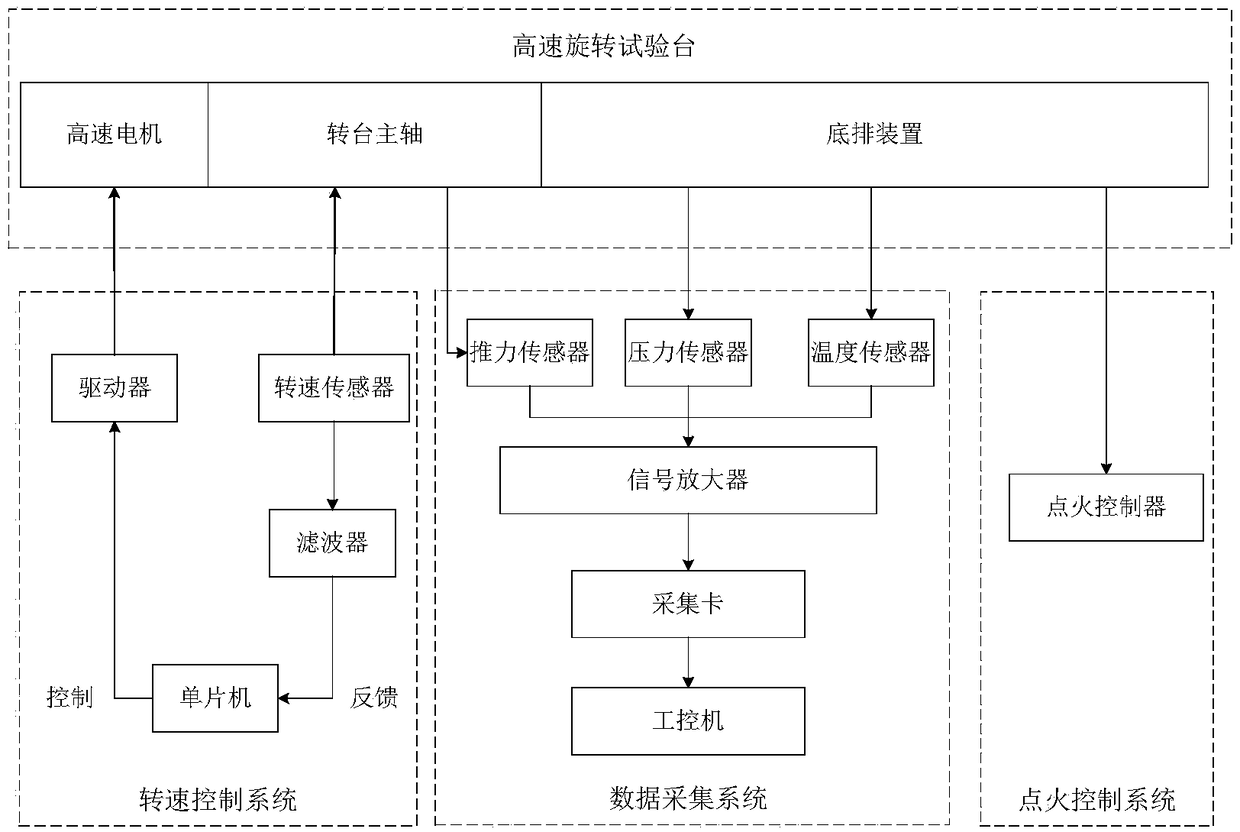

High-speed rotating combustion test system for base bleed unit

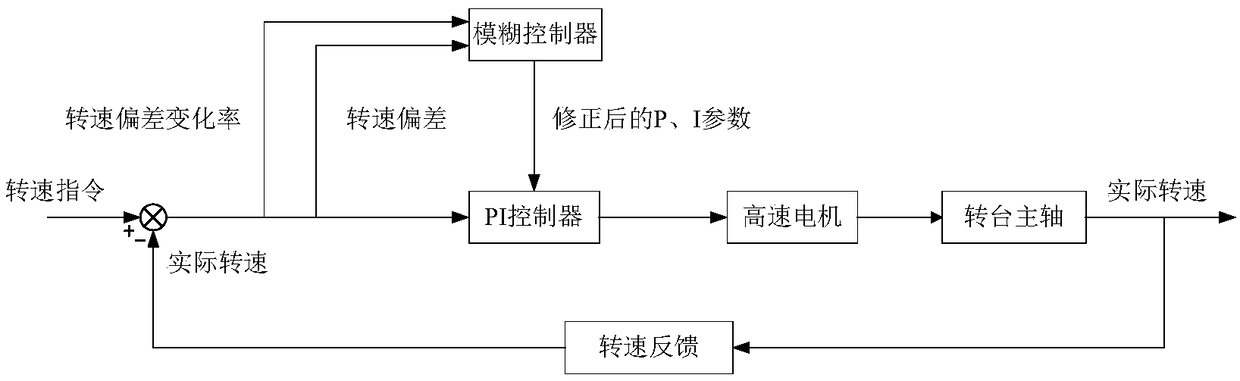

A high-speed rotation and rotation test technology, which is applied in ammunition tests, offensive equipment, ammunition, etc., can solve problems such as eliminating static errors, insufficient interference suppression capabilities, and inability to meet the speed control accuracy requirements of the turntable system at all times, achieving wide versatility , high reliability, and high speed control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0021] The working process of the system is illustrated below by taking the rotating combustion experiment of the bottom row device of a certain type of 130mm bottom row extended range bomb as an example:

[0022] Firstly, the parameters are initialized and set. The high-speed motor drives the bottom row device to the initial speed, which is the speed at the time of ignition, and stabilizes at this speed. Prepare to fire the bottom row of units while the other systems are ready in place. While the ignition controller is igniting, it sends a pulse ignition command to the acquisition card and the single-chip microcomputer. After the acquisition card receives the ignition command, the industrial computer starts to display and record various data information; the single-chip microcomputer starts to control the bottom row. The speed information fed back by the speed sensor is processed by the fuzzy PI controller, and the single-chip microcomputer is driven to change the voltage val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com