LCOS (Liquid Crystal On Silicon) displayer and electronic equipment

A display and pixel electrode technology, which is applied in the field of LCOS displays and electronic equipment, can solve problems such as unfavorable product performance, failure to meet low power consumption products, and high power consumption of driving voltage, so as to reduce battery effect, ensure voltage control, and improve product performance. reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the purpose and features of the present invention more obvious and understandable, the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. However, the present invention can be implemented in different forms and should not be limited to the described embodiments.

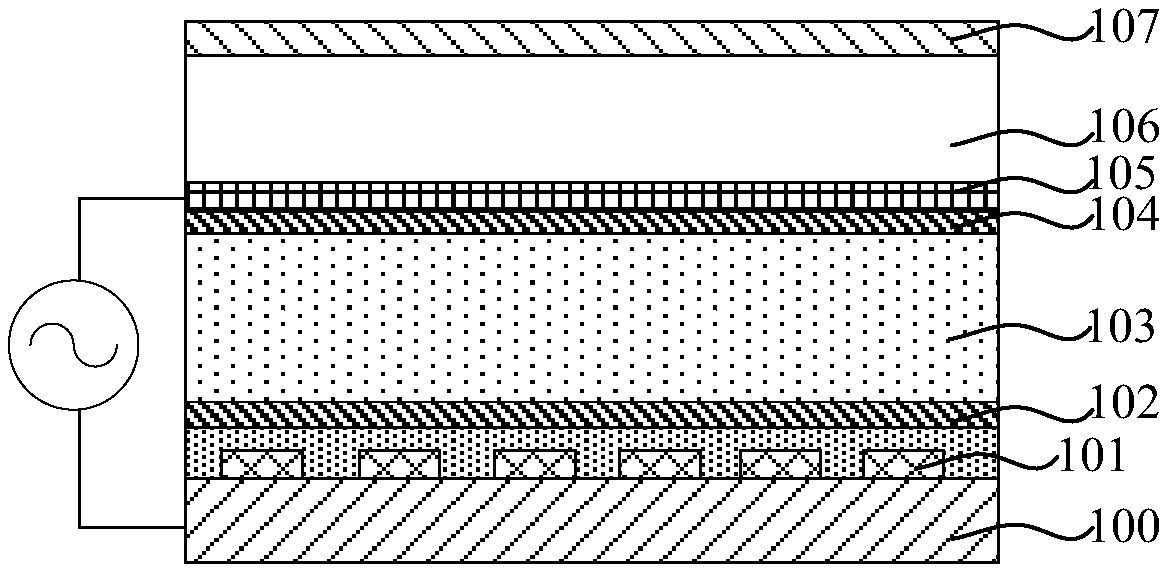

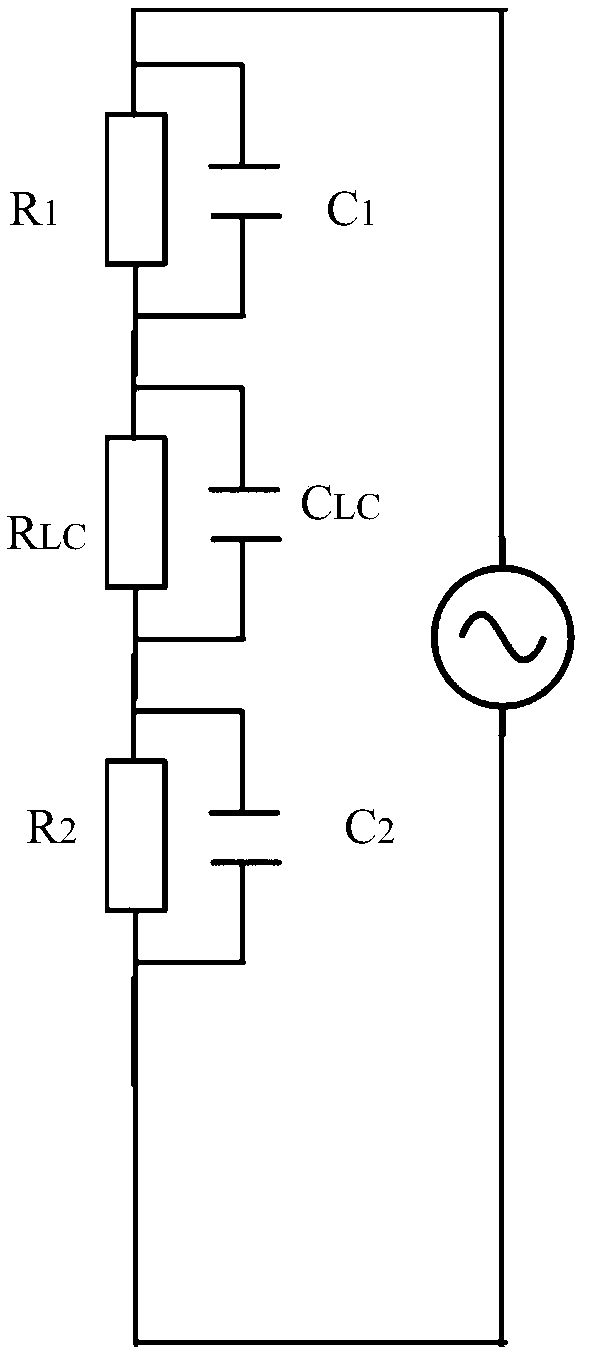

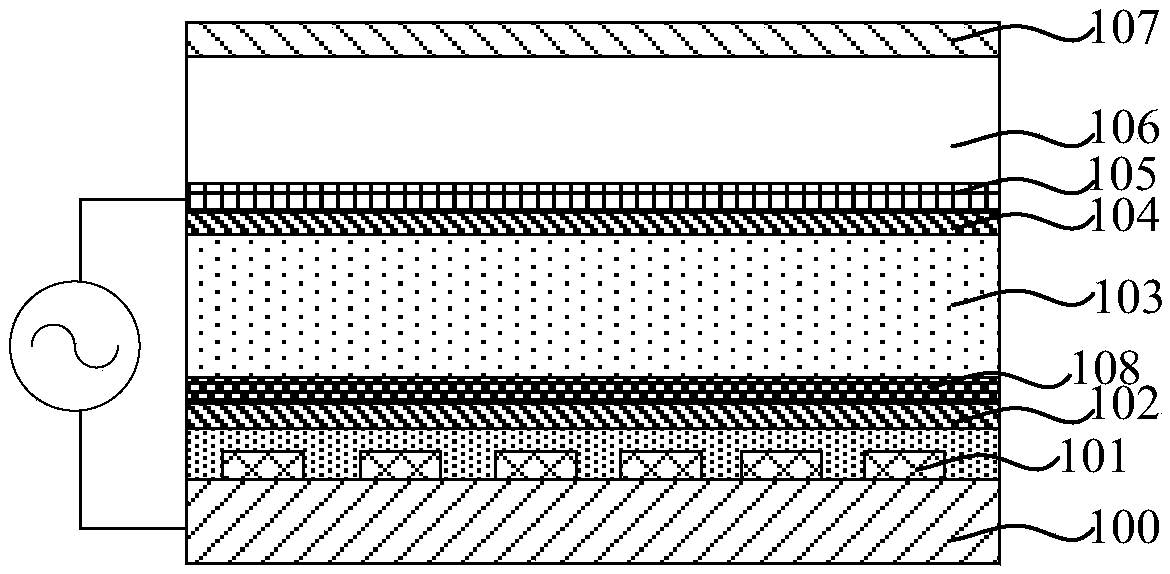

[0032] Please refer to Figure 4A to Figure 4C , the present invention provides an LCOS display, comprising a wafer substrate 300, a mirror stack 301, a pixel electrode layer 302, a first alignment layer 303, a liquid crystal layer 304, a second alignment layer 305, a transparent conductive layer 306, a transparent The cover plate 307, the anti-reflection layer 308, and the conductive via structure 300b.

[0033]Wherein, the wafer substrate 300 may be any suitable semiconductor material known to those skilled in the art, such as silicon, germanium, silicon germanium, silicon carbide, silicon-on-insulator, germanium-on-i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com