Method of utilizing Tween emulsifier to prepare microcapsule tributyrin

A technology of tributyrin and microcapsules, which is applied in application, animal feed, additional food elements, etc., can solve the problems of unfavorable transportation and storage, easy rancidity and oxidation, and insoluble in water, etc., to achieve extended storage period, dispersibility and Solubility Enhancement and Odor Reduction Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

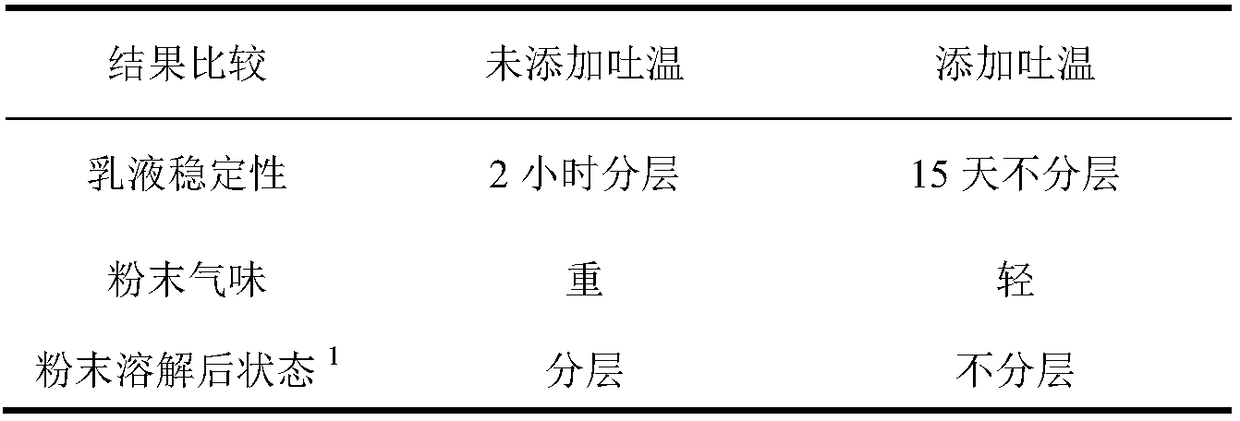

[0026] Whether embodiment 1 adds the impact of Tween on the preparation of microcapsule tributyrin

[0027] The preparation process of microcapsule tributyrin is carried out according to the following steps: take cornstarch milk with a mass concentration of 200g / L as raw material, add 2U / (g starch wet basis) cyclodextrin glucosyltransferase and liquefy at 90°C 30min, after cooling to 45°C, add 2U / (g starch wet base) cyclodextrin glucosyltransferase to cyclize at 45°C for 12h, add tributyrin after the reaction, the mass ratio of the added amount to corn starch is 0.50:1, and tributyrin is pre-mixed with ethanol at a mass ratio of 3:1. Add Tween 20 emulsifier to the above solution for mixing, the mass ratio of Tween 20 to corn starch is 0.3:1, and the high-speed shearing machine is 8000-20000rpm to increase the high-speed shearing of the above solution for 2-5 minutes, and then The obtained emulsion is homogenized to obtain a uniform and stable emulsion, the homogenization pres...

Embodiment 2

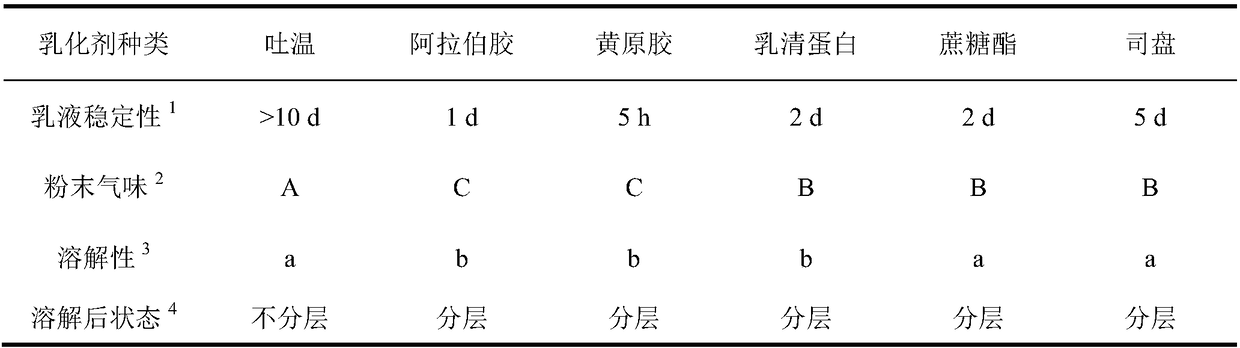

[0032] The impact of embodiment 2 emulsifier types on the preparation of microcapsule oil

[0033] The preparation process of microcapsule tributyrin is carried out according to the following steps: take cornstarch milk with a mass concentration of 200g / L as raw material, add 2U / (g starch wet basis) cyclodextrin glucosyltransferase and liquefy at 90°C 30min, after cooling to 45°C, add 2U / (g starch wet base) cyclodextrin glucosyltransferase to cyclize at 45°C for 12h, add tributyrin after the reaction, the mass ratio of the added amount to corn starch is 0.50:1, and tributyrin is pre-mixed with ethanol at a mass ratio of 3:1. Add an emulsifier to the above solution for mixing. The mass ratio of the amount of emulsifier to cornstarch is 0.3:1, and the high-speed shearing machine is 8000-20000rpm to increase the high-speed shearing of the above solution for 2-5 minutes, and then the obtained emulsion Homogenizing to obtain a uniform and stable emulsion, the homogenizing pressure...

Embodiment 3

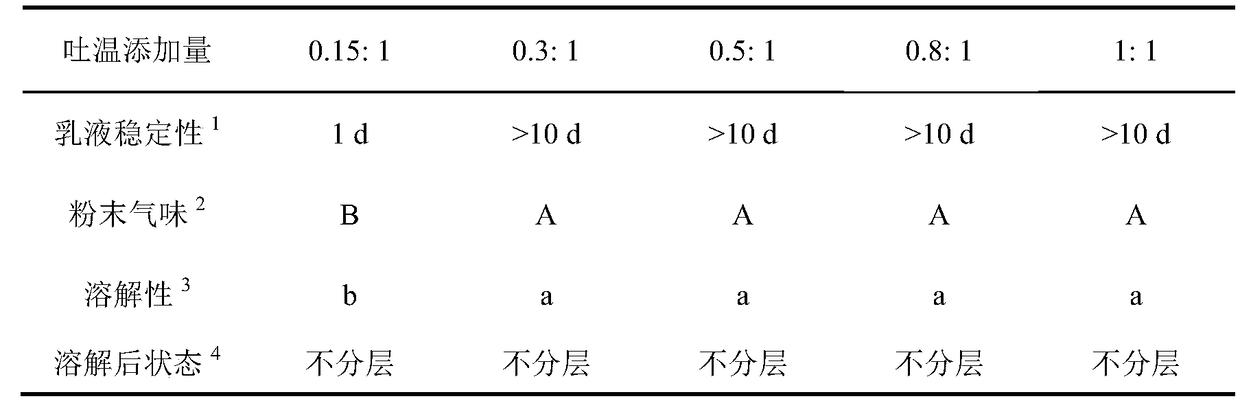

[0041] The influence of embodiment 3 Tween types on the preparation of microcapsule oil

[0042]The preparation process of microcapsule tributyrin is carried out according to the following steps: take cornstarch milk with a mass concentration of 200g / L as raw material, add 2U / (g starch wet basis) cyclodextrin glucosyltransferase and liquefy at 90°C 30min, after cooling to 45°C, add 2U / (g starch wet base) cyclodextrin glucosyltransferase to cyclize at 45°C for 12h, add tributyrin after the reaction, the mass ratio of the added amount to corn starch is 0.5:1, and tributyrin is pre-mixed with ethanol at a mass ratio of 3:1. Add Tween emulsifier to the above solution for mixing, the mass ratio of Tween addition to corn starch is 0.3:1, high-speed shearing machine 8000-20000rpm gradually increases the high-speed shearing of the above solution for 2-5min, and then the obtained The emulsion is homogenized to obtain a uniform and stable emulsion, the homogenization pressure is 30-40 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com