Processing method of high-quality minced fish product containing fish roe grains

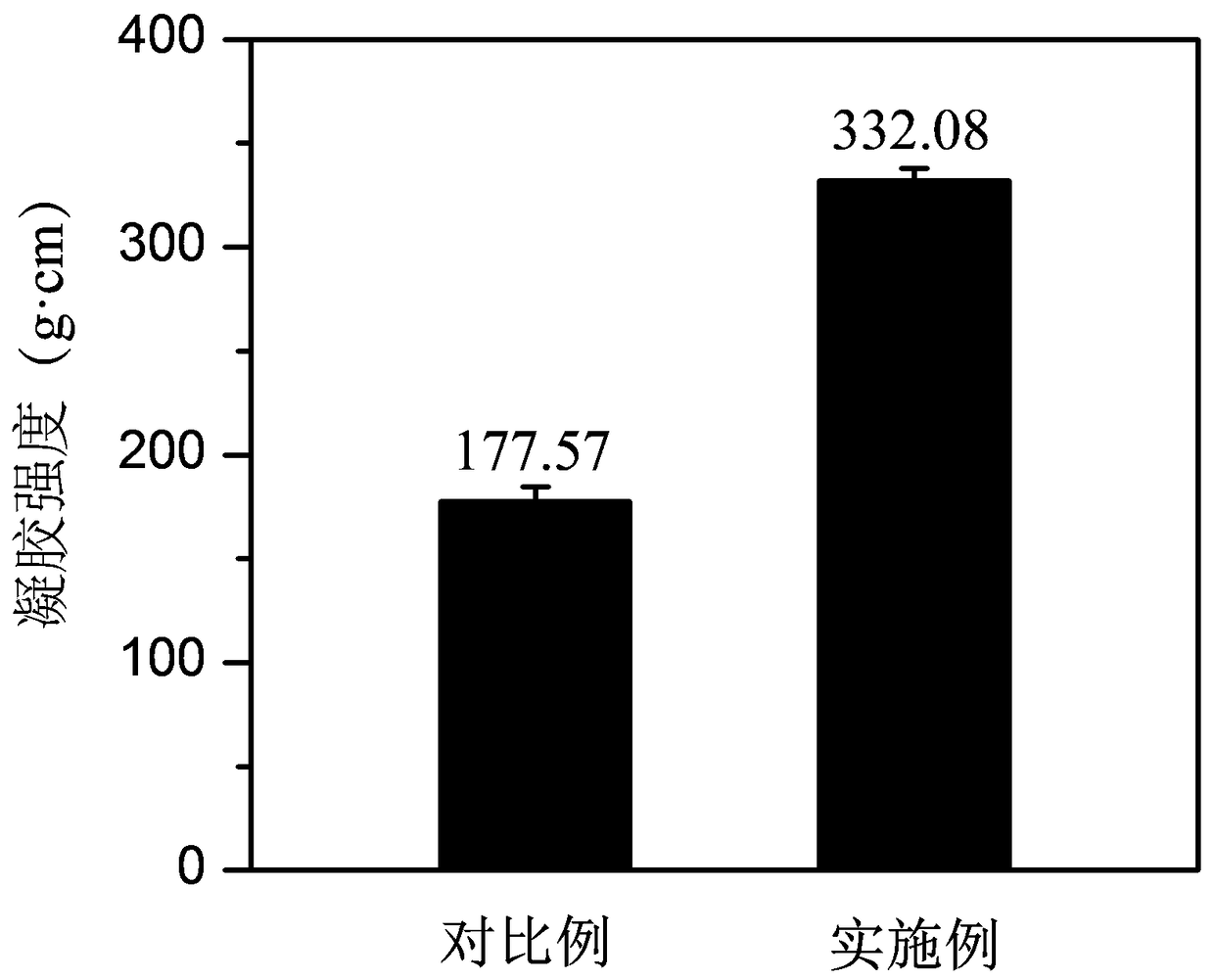

A technology of surimi products and processing methods, which is applied in the direction of food ingredients as taste improvers, food science, etc., can solve the problems of surimi product gel deterioration, market development resistance, and failure to reach products, so as to prevent waste heat and cooling time Too long, significant difference in gel strength, guaranteed tenderness and crispness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

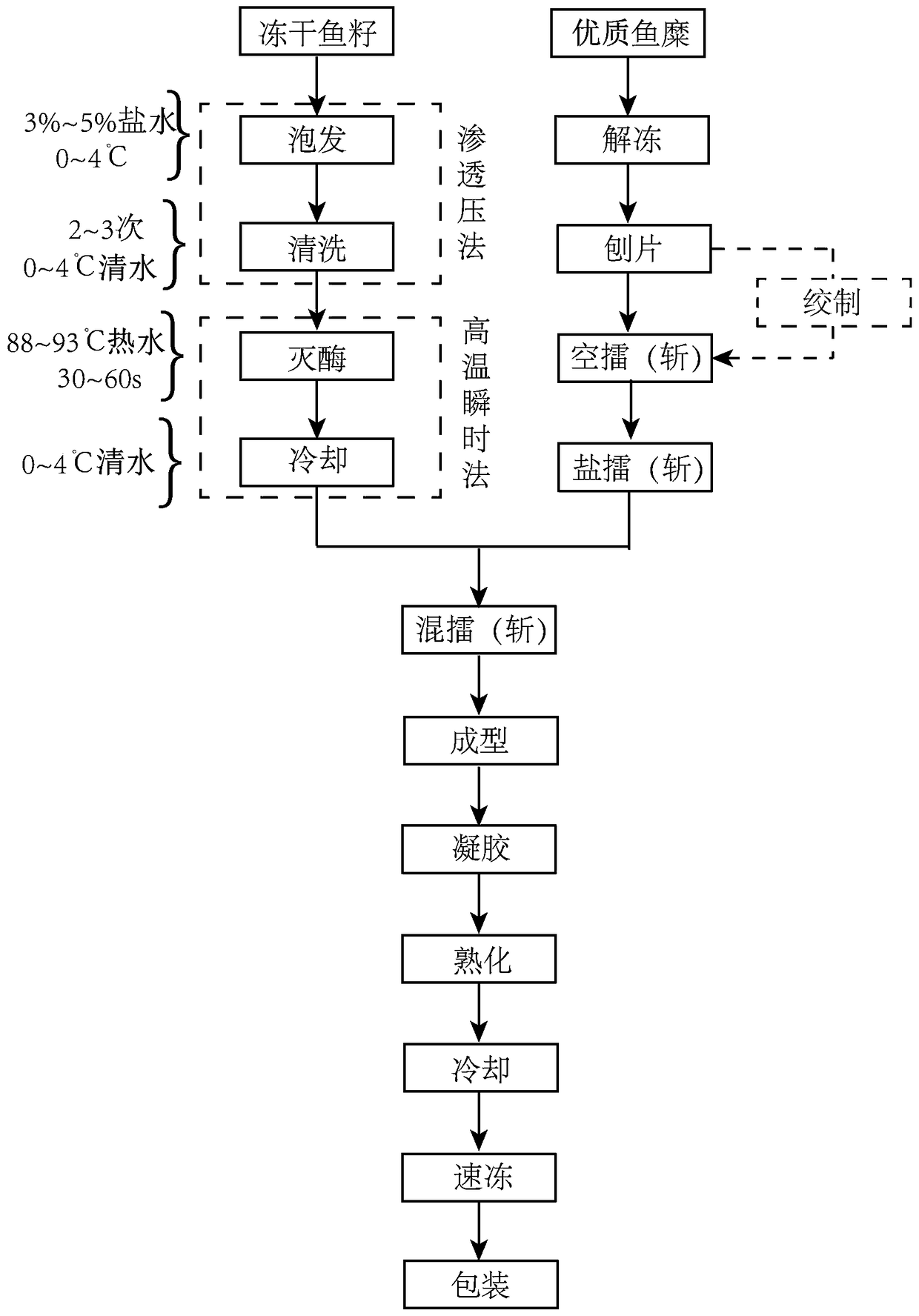

[0040] The present invention obtains fish roe balls containing fish roe particles through the following steps.

[0041] (1) Soak the freeze-dried fish roe in 3% salt water at 0 ~ 4°C for 2 hours, and stir once every 15 minutes, in which the volume of the salt water is not less than 3 times the volume of the fish roe;

[0042] (2) Wash the soaked fish roe in clean water at 0-4°C for 3 times. The volume of clean water is not less than the volume of the soaked fish roe. After cleaning, filter and dry with a sieve;

[0043] (3) The dried fish roe is blanched in hot water at 90°C for 45 seconds to inactivate the enzyme until the surface hardens slightly and the interior remains liquid. Stirring is required during the inactivation process;

[0044] (4) Transfer the fish roe to clean water at 0-4°C and cool it down to below 4°C, filter it dry with a sieve, and obtain prefabricated fish roe for later use;

[0045] (5) Indian gold thread surimi with a gel strength ≥ 500g·cm is thawed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Gel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com