Embroidering product capable of rapidly eliminating swelling, inhibiting bacteria and repairing skin and preparation method of embroidering product

A skin-repairing and rapid technology, applied in the field of tattoo and embroidery, can solve the problems of limited promotion, single effect and incompleteness, and achieve the effect of remarkable specificity, comprehensive effect, and elimination of inflammation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] This embodiment provides a preparation method of a tattoo product that rapidly reduces swelling, inhibits bacteria, and repairs the skin, including the following steps:

[0026] (1) preparing sodium hyaluronate, comprises the steps:

[0027] (1) Cultivate the fermentation broth of Streptococcus zooepidemicus. After the completion, keep the fermentation broth of Streptococcus zooepidemicus at 70°C for 2 hours, then add trichloroacetic acid to adjust the pH of the system to 4.5, and then sterilize it. liquid;

[0028] (2) Add diatomite to the sterilized fermentation broth, the weight ratio of diatomite to the sterilized fermentation broth is 1:100, and then filter at 70°C to obtain sodium hyaluronate.

[0029] (II) Preparation of tattoo products:

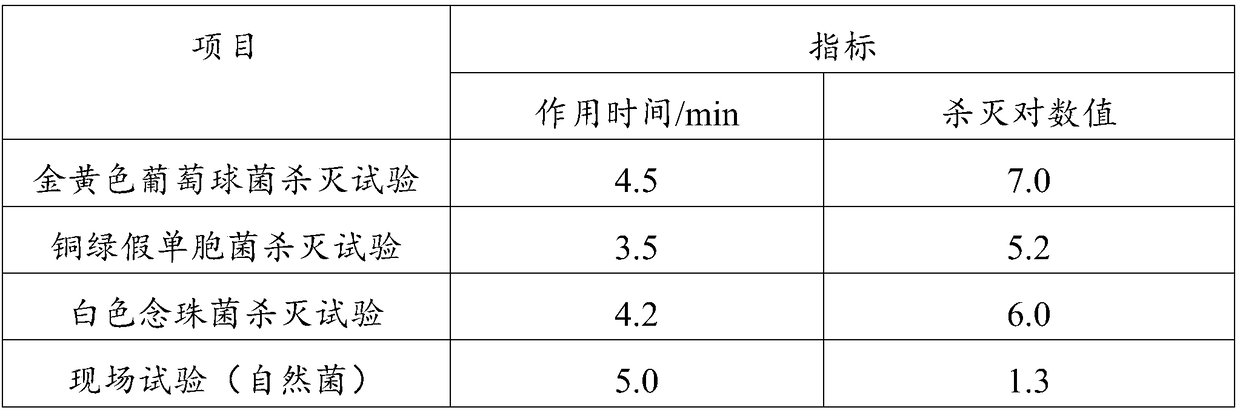

[0030] Mix 50g Panax notoginseng extract with a particle size of 800-850 mesh, 200g EGF, 30g clindamycin, 250g sodium hyaluronate and 450g distilled water with a conductivity of 0.05mS / m at a speed of 60r / min for 30min to obt...

Embodiment 2

[0032] This embodiment provides a preparation method of a tattoo product that rapidly reduces swelling, inhibits bacteria, and repairs the skin, including the following steps:

[0033] (1) preparing sodium hyaluronate, comprises the steps:

[0034] (1) Cultivate the fermentation liquid of Streptococcus zooepidemicus. After the completion, keep the fermentation liquid of Streptococcus zooepidemicus at 80°C for 1 hour, then add trichloroacetic acid to adjust the pH of the system to 4.8, and then sterilize it. After the completion, sterilized fermentation is obtained liquid;

[0035] (2) Add diatomite to the sterilized fermentation broth, the weight ratio of diatomite to the sterilized fermentation broth is 2:100, and then filter at 60°C to obtain sodium hyaluronate.

[0036] (II) Preparation of tattoo products:

[0037] Mix 150g Panax notoginseng extract with a particle size of 950-1000 mesh, 100g EGF, 70g clindamycin, 150g sodium hyaluronate and 550g distilled water with a co...

Embodiment 3

[0039] This embodiment provides a preparation method of a tattoo product that rapidly reduces swelling, inhibits bacteria, and repairs the skin, including the following steps:

[0040] (1) preparing sodium hyaluronate, comprises the steps:

[0041] (1) Cultivate the fermented liquid of Streptococcus zooepidemicus. After the completion, keep the fermented liquid of Streptococcus zooepidemicus at 75°C for 1.5 hours, then add trichloroacetic acid to adjust the pH of the system to 4.6, and then sterilize it. fermentation broth;

[0042] (2) Add diatomite to the sterilized fermentation broth, the weight ratio of diatomite to the sterilized fermentation broth is 1.5:100, and then filter at 65°C to obtain sodium hyaluronate.

[0043] (II) Preparation of tattoo products:

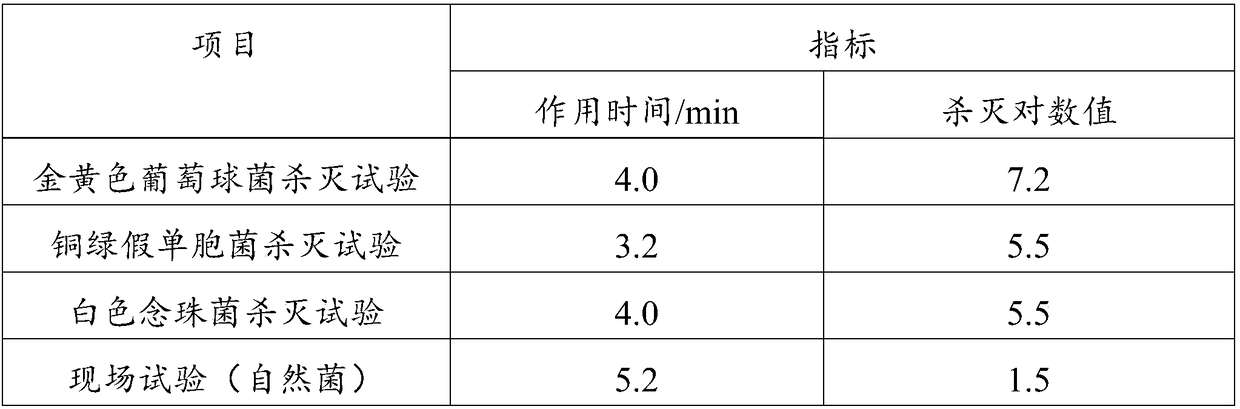

[0044] Mix 100g Panax notoginseng extract with a particle size of 850-950 mesh, 150g EGF, 50g clindamycin, 200g sodium hyaluronate and 500g distilled water with a conductivity of 0.1mS / m at a speed of 70r / min for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com