Graphene/teflon film for wastewater treatment and preparation method thereof

A technology of polytetrafluoroethylene membrane and polytetrafluoroethylene, which is applied in the direction of permeation/dialysis water/sewage treatment, chemical instruments and methods, membrane technology, etc., can solve the problem of low filtration efficiency, narrow pore range, and impractical retention of impurities To achieve the effect of enhancing the adsorption effect, improving the adsorption and filtration efficiency, improving the filtered water flow and purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

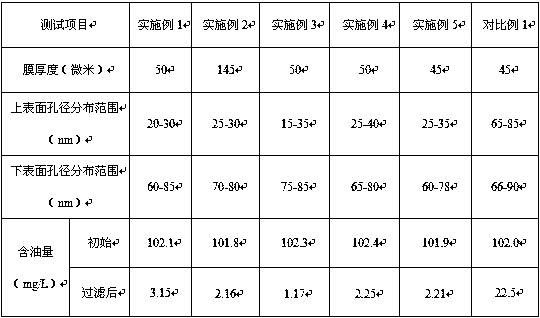

Examples

Embodiment 1

[0032] a. Evenly mix 75 parts by weight of polytetrafluoroethylene powder, 10 parts by weight of graphene, and 5 parts by weight of silica aerogel, heat and melt in the extruder to form a melt extrusion, and each section of the extruder is heated The temperature is 300°C in the first stage, 330°C in the second stage, 340°C in the third stage, and 310°C in the fourth stage. A composite base film was formed by three-roll calendering; the rolling speed of the film-forming rolls was 30 m / min, and the temperature difference between the rolls was 10°C. The pore size of silica airgel is 15-20nm.

[0033] b. First, the base film is stretched longitudinally, and the stretching ratio of the longitudinal stretching is 25 times, and then the transverse stretching is carried out; the transverse stretching ratio is 20 times; Liquid nitrogen is used for quenching, and the flow rate of liquid nitrogen is controlled so that the quenching surface temperature of the upper surface is 180°C, and ...

Embodiment 2

[0036] a. Evenly mix 80 parts by weight of polytetrafluoroethylene powder, 5 parts by weight of graphene, and 5 parts by weight of silica airgel, heat and melt in the extruder to form a melt extrusion, and each section of the extruder is heated The temperature is 310°C in the first stage, 320°C in the second stage, 340°C in the third stage, and 310°C in the fourth stage. A composite base film was formed by three-roll calendering; the rolling speed of the film-forming rolls was 30 m / min, and the temperature difference between the rolls was 10°C. The pore size of silica airgel is 15-20nm.

[0037] b. First, the base film is stretched longitudinally, and the stretching ratio of the longitudinal stretching is 25 times, and then the transverse stretching is carried out; the multiple of the transverse stretching is 25 times; Liquid nitrogen is used for quenching, and the flow rate of liquid nitrogen is controlled so that the quenching surface temperature of the upper surface is 180...

Embodiment 3

[0040] a. Evenly mix 85 parts by weight of polytetrafluoroethylene powder, 15 parts by weight of graphene, and 5 parts by weight of silica airgel, heat and melt in the extruder to form a melt extrusion, and each section of the extruder is heated The temperature is 310°C in the first stage, 320°C in the second stage, 330°C in the third stage, and 310°C in the fourth stage. A composite base film was formed by three-roll calendering; the rolling speed of the film-forming rolls was 60 m / min, and the temperature difference between the rolls was 10°C. The pore size of silica airgel is 15-20nm.

[0041] b. First, the base film is stretched longitudinally, and the stretching ratio of the longitudinal stretching is 30 times, and then it is stretched laterally; the multiple of the lateral stretching is 20 times; Liquid nitrogen is used for quenching, and the flow rate of liquid nitrogen is controlled so that the quenching surface temperature of the upper surface is 180°C, and the quenc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap