Modified nonwoven fabric capable of quickly adsorbing heavy metal ions and preparation method thereof

A technology for adsorbing heavy metals and non-woven fabrics. It is applied in the fields of alkali metal compounds, chemical instruments and methods, and adsorption water/sewage treatment. It can solve the problems of long adsorption equilibrium time, low adsorption capacity of heavy metal ions, and small specific surface area of ordinary fibers. problems, to achieve the effect of fast adsorption speed, large adsorption capacity and short adsorption equilibrium time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

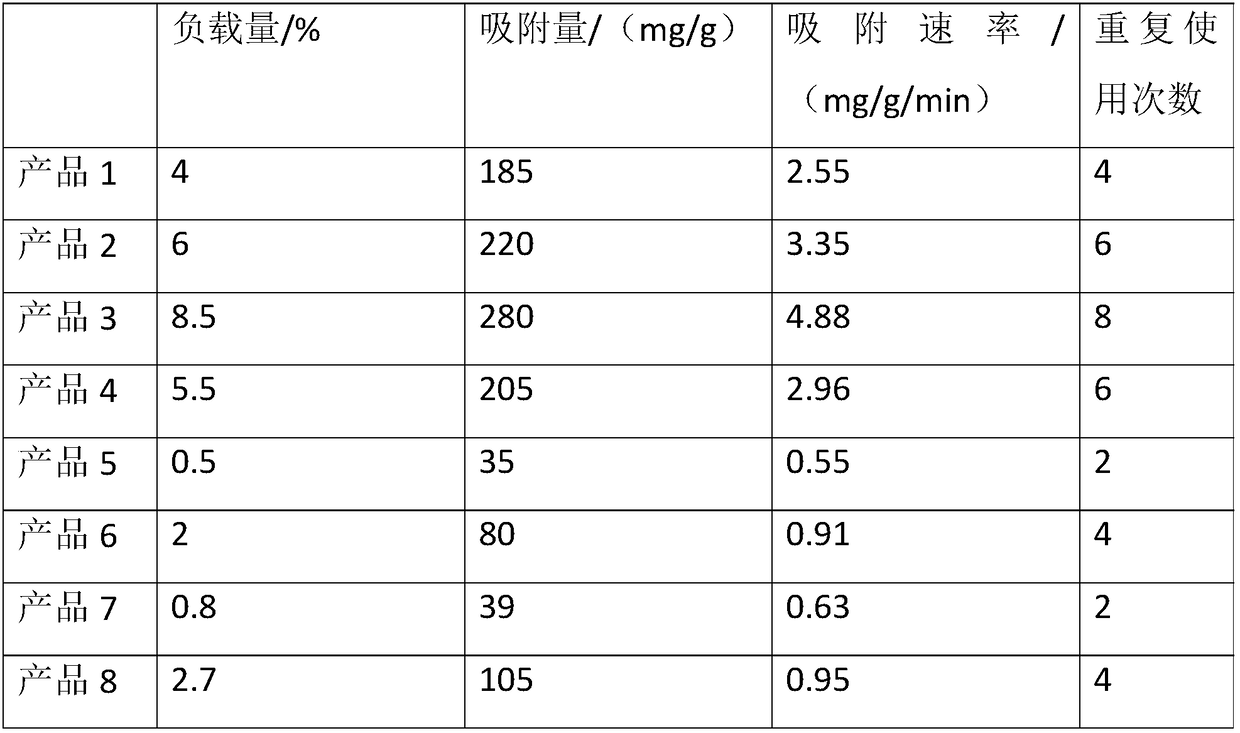

Examples

Embodiment 1

[0031] A kind of preparation method of the modified non-woven fabric that fast absorbs heavy metal ion, concrete implementation steps are as follows:

[0032] (1) 2g polypropylene nonwoven fabric (gram weight 60g / m 2 , thickness 295 μm) was treated with ethanol ultrasonic vibration to remove organic impurities on the surface, and then dried;

[0033] (2) Preparation of buffer solution

[0034] Prepare a tris(hydroxymethyl)aminomethane hydrochloride buffer solution whose pH is 8.0 with a concentration of 0.01mol / L;

[0035] (3) Based on the total weight of the modified solution, 0.2wt% catechol and 0.2wt% diethylenetriamine were dissolved in the buffer solution to prepare a modified solution with a volume of 300ml;

[0036] (4) Soak the polypropylene nonwoven fabric of step (1) in the modified solution for 10 hours to obtain the modified nonwoven fabric;

[0037] (5) Wash and dry the modified nonwoven fabric.

[0038] Wherein the modified nonwoven fabric in the step (5) is ...

Embodiment 2

[0040] A kind of preparation method of the modified non-woven fabric that fast absorbs heavy metal ion, concrete implementation steps are as follows:

[0041] (1) 2g polyester nonwoven fabric (gram weight 70g / m 2 , thickness 395 μm) was treated with ethanol ultrasonic vibration to remove organic impurities on the surface, and then dried;

[0042] (2) Preparation of buffer solution

[0043] Prepare a tris(hydroxymethyl)aminomethane hydrochloride buffer solution whose pH is 8.0 with a concentration of 0.01mol / L;

[0044] (3) Based on the total weight of the modified solution, 0.2wt% dopamine and 0.4wt% diethylenetriamine were dissolved in the buffer solution to prepare a modified solution with a volume of 300ml;

[0045] (4) Soak the polyester nonwoven fabric in step (1) in the modification solution for 24 hours to obtain the modified nonwoven fabric;

[0046] (5) Wash and dry the modified nonwoven fabric.

[0047] Wherein in step (5), the modified nonwoven fabric is cleaned...

Embodiment 3

[0049] A kind of preparation method of the modified non-woven fabric that fast absorbs heavy metal ion, concrete implementation steps are as follows:

[0050] (1) 2g nylon non-woven fabric (gram weight 60g / m 2 , with a thickness of 255 μm) was treated with ultrasonic vibration of ethanol to remove organic impurities on the surface, and then dried;

[0051] (2) Preparation of buffer solution

[0052] Prepare a tris(hydroxymethyl)aminomethane hydrochloride buffer solution whose pH is 8.5 with a concentration of 0.01mol / L;

[0053] (3) Based on the total weight of the modified solution, 0.4wt% dopamine and 0.8wt% polyethyleneimine were dissolved in a buffer solution to prepare a modified solution with a volume of 300ml;

[0054] (4) Soak the nylon nonwoven fabric of step (1) in the modification solution, and soak for 24 hours to obtain the modified nonwoven fabric;

[0055] (5) Wash and dry the modified nonwoven fabric.

[0056]Wherein in step (5), the modified nonwoven fabri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com