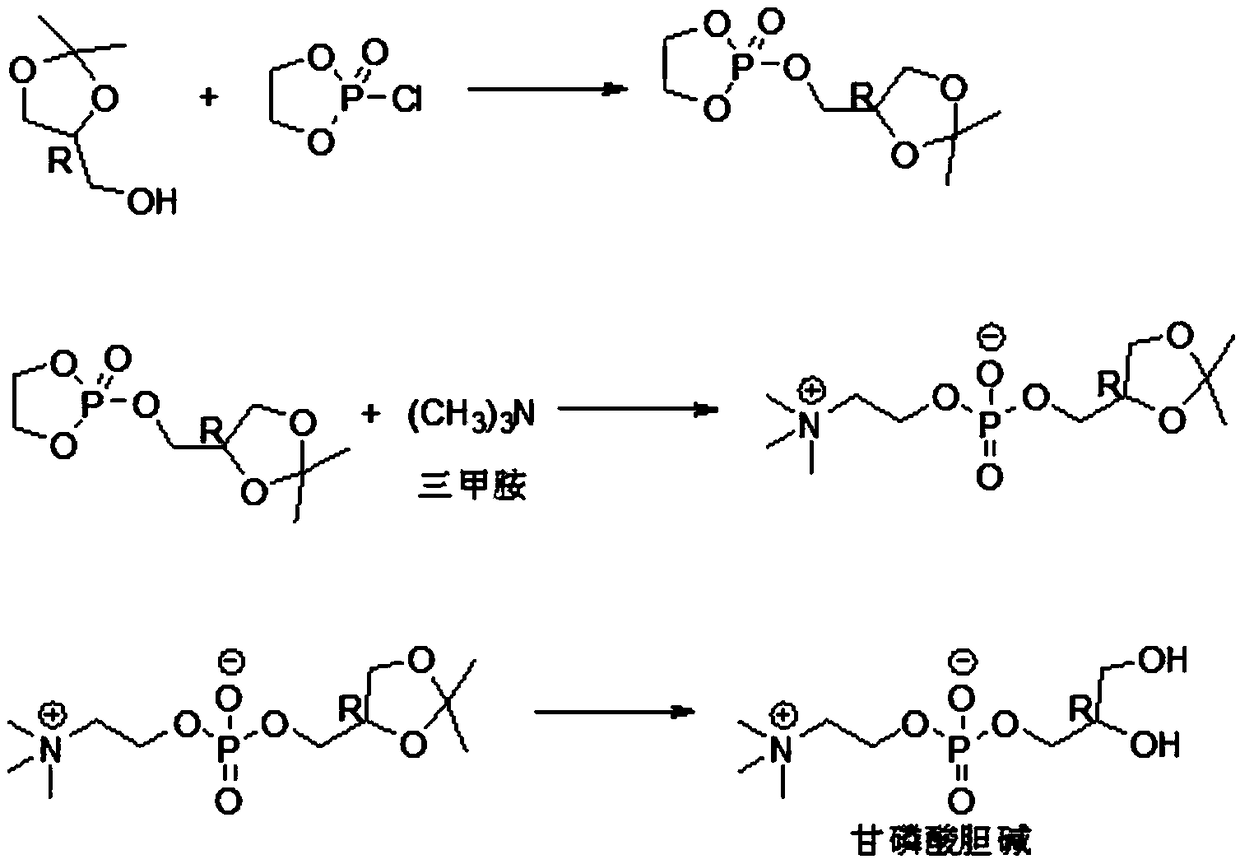

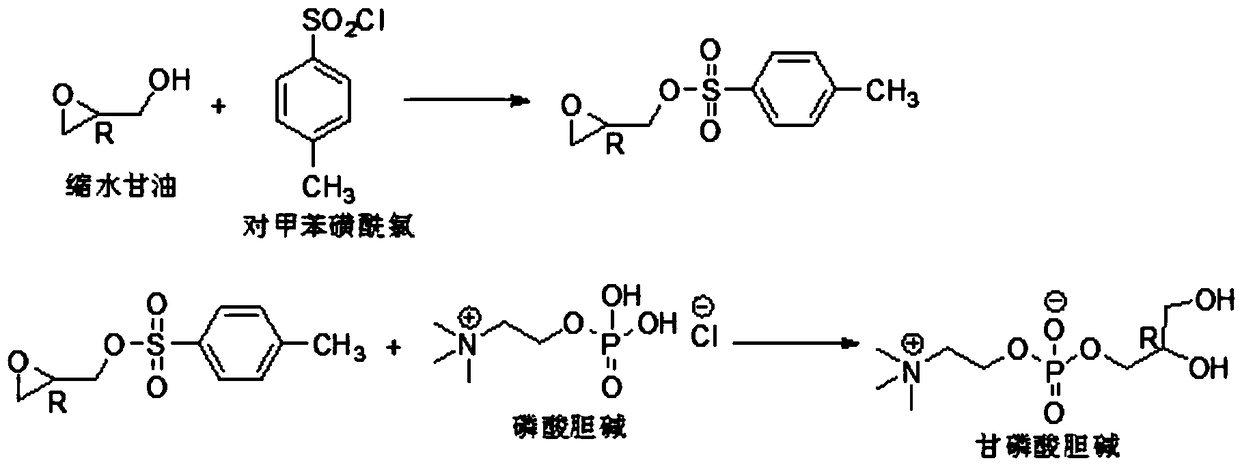

Synthetic catalyst for L-alpha glycerylphosphorylcholine and preparation method thereof

A technology of glycerol phosphatidylcholine and catalyst, which is applied in the field of synthesis catalyst of glycerol phosphatidylcholine and its preparation, which can solve the problems of low yield and achieve the effects of promoting preparation, easy availability of raw materials, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The present invention provides a kind of preparation method of the synthesis catalyst of glycerol phosphatidylcholine, comprising:

[0022] 1) mixing vanadium chloride, copper salt, tin salt, expanded vermiculite and alcohol to form a mixed solution;

[0023] 2) mixing the mixed solution and water, and then performing a solvothermal reaction to obtain a reaction product;

[0024] 3) Calcining the reaction product to obtain the synthesis catalyst of glycerol phosphatidylcholine.

[0025] In step 1) of the above-mentioned preparation method, the consumption of materials can be selected in a wide range, but in order to further improve the catalytic efficiency of the catalyst, preferably, in step 1), the vanadium chloride, copper salt, tin salt , The dosage ratio of expanded vermiculite to alcohol is 10mmol: 1-1.5mmol: 2.5-4mmol: 0.1-0.4mmol: 20-40mL.

[0026] In step 2) of the above-mentioned preparation method, the consumption of materials can be selected in a wide rang...

Embodiment 1

[0034] 1) Vanadium chloride, copper salt (copper chloride), tin salt (tin methanesulfonate), expanded vermiculite and alcohol (ethanol) according to 10mmol: 1-1.5mmol: 2.5-4mmol: 0.1-0.4g: 20 -40mL is mixed in proportion (mixing temperature is 25°C, mixing time is 50min) to form a mixed solution;

[0035] 2) Mix the mixed solution and water according to the volume ratio of 1:1.8 (the mixing temperature is 25°C, the mixing time is 50min), and then carry out solvothermal reaction (the reaction temperature is 130°C, the reaction time is 7h) to obtain the reaction product;

[0036] 3) The reaction product is calcined (from 25°C to 200°C at a rate of 1.8°C / min and kept for 3 hours, then heated to 470°C at a rate of 1°C / min and kept for 3.5 hours, then cooled to 25°C) to obtain the synthesis catalyst A1 of the glycerol phosphatidylcholine.

Embodiment 2

[0038] 1) Vanadium chloride, copper salt (copper sulfate), tin salt (tin ethanesulfonate), expanded vermiculite and alcohol (propanol) according to 10mmol: 1-1.5mmol: 2.5-4mmol: 0.1-0.4g: 20-40mL is mixed in proportion (mixing temperature is 15°C, mixing time is 60min) to form a mixed solution;

[0039] 2) Mix the mixed solution and water according to the volume ratio of 1:1.5 (the mixing temperature is 15°C, the mixing time is 60min), and then perform solvothermal reaction (the reaction temperature is 120°C, the reaction time is 8h) to obtain the reaction product;

[0040] 3) Calcining the reaction product (increasing the temperature from 15°C to 180°C at a rate of 1.5°C / min and maintaining it for 2 hours, then raising the temperature to 450°C at a rate of 0.8°C / min and maintaining it for 3 hours, then cooling to 15°C ℃) to prepare the synthesis catalyst A2 of the glycerol phosphatidylcholine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com