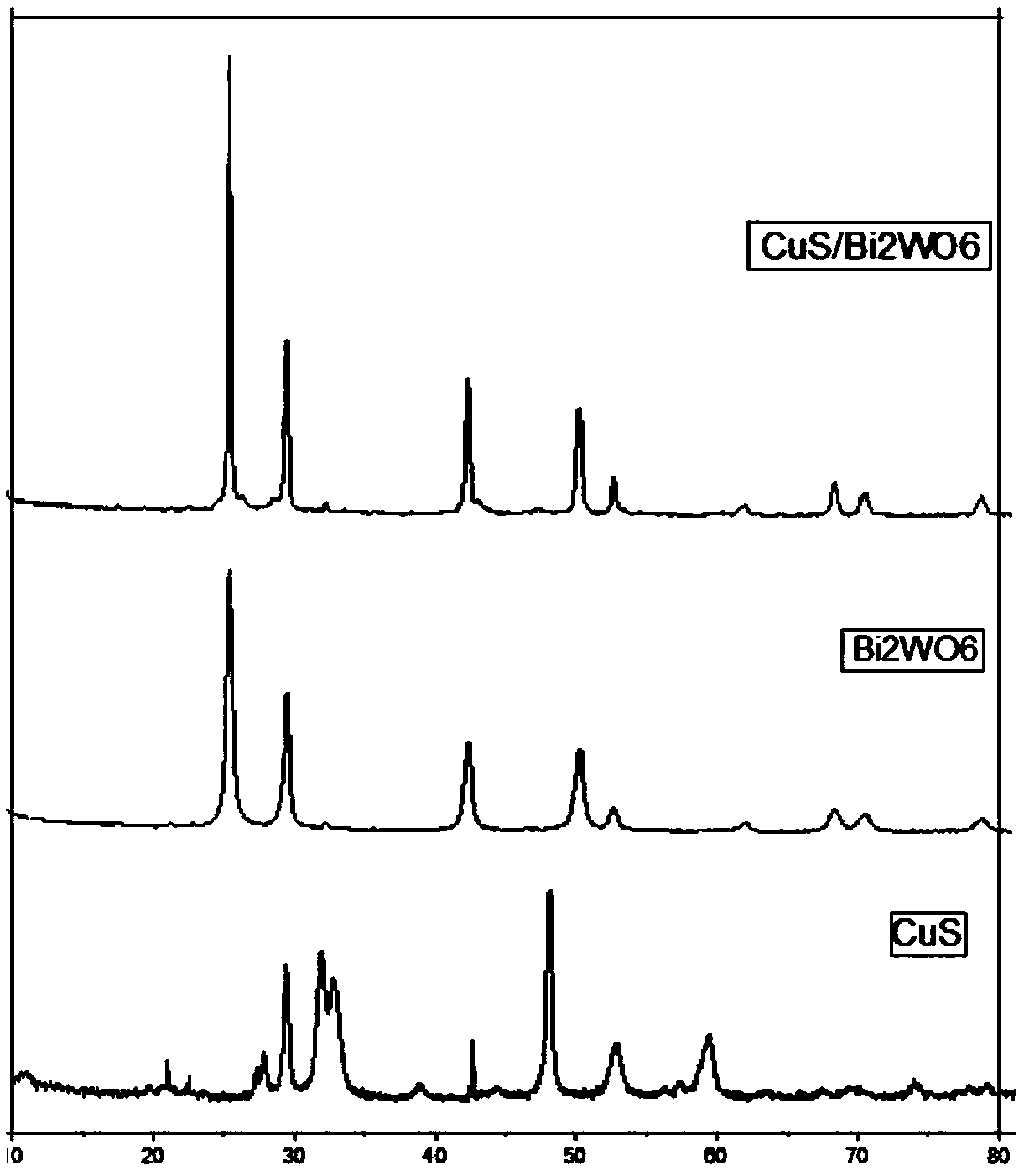

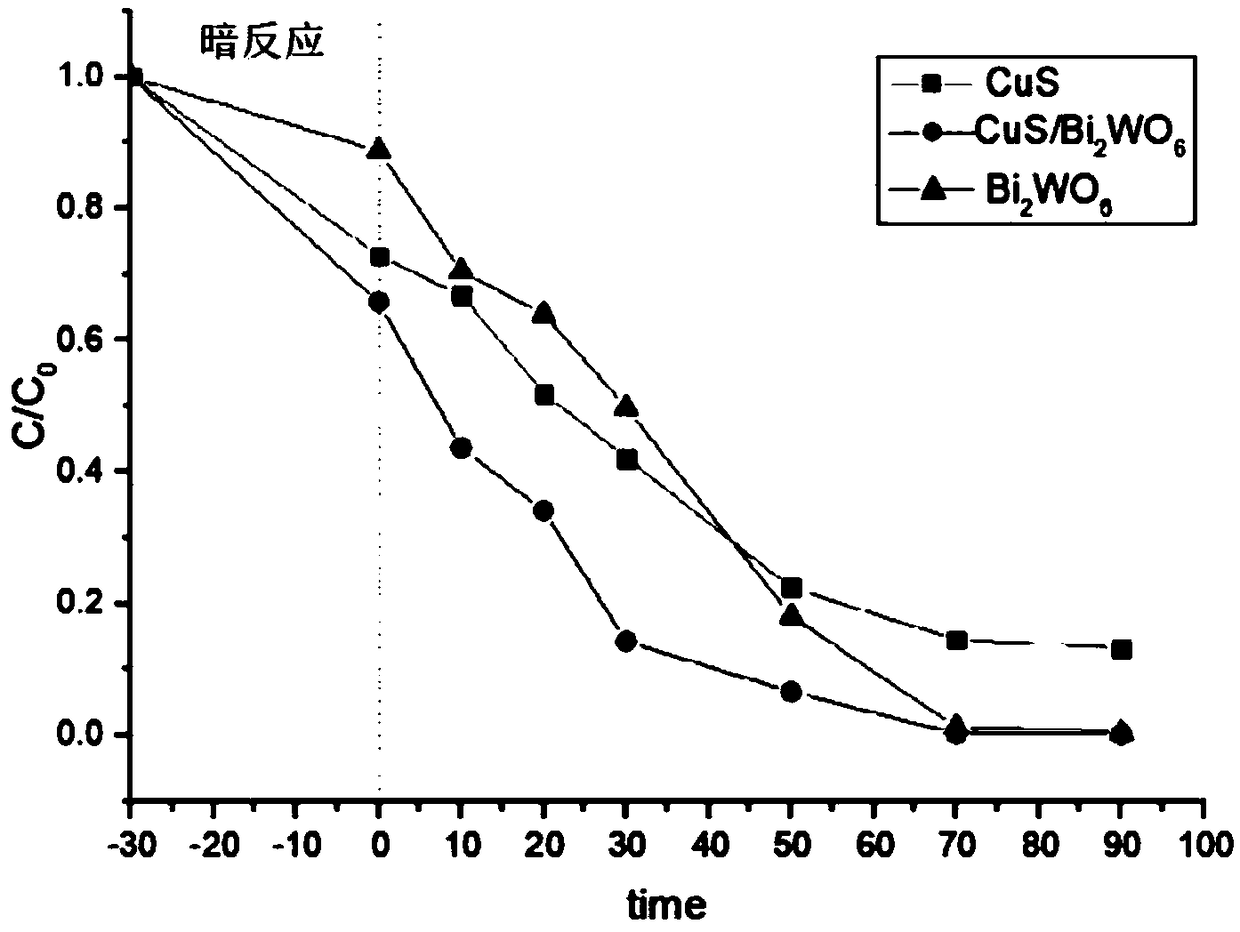

CuS/Bi2WO6 heterojunction photocatalyst as well as preparation method and application thereof

A photocatalyst and heterojunction technology, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc. It can solve the problems of limited contact area, environmental pollution by other substances, preparation The process is cumbersome and other problems, to achieve the effect of enhanced absorption range, simple preparation process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A CuS / Bi 2 WO 6 Heterojunction photocatalyst, its preparation method comprises the following steps:

[0026] (1) At room temperature, weigh 0.25 mmol of copper acetate solid and dissolve it in 40 mL of ethylene glycol to form solution A;

[0027] (2) Weigh 1mmol thiourea and dissolve it in 40mL ethylene glycol to form solution B;

[0028] (3) Mix solution A and solution B evenly, add 1mmol Bi to the mixed solution 2 WO 6 Solid powder, stir evenly;

[0029] (4) 36% acetic acid solution was dripped dropwise into the mixed solution obtained in step (3) under stirring condition, until the pH value of the mixed solution was 4, and continued to stir for 30 min;

[0030] (5) Transfer the mixed solution obtained in step (4) into a 100mL hydrothermal kettle, react at 160°C for 12h, cool naturally to room temperature, alternately wash with deionized water and absolute ethanol, and dry at 80°C to prepare have to.

Embodiment 2

[0032] A CuS / Bi 2 WO 6 Heterojunction photocatalyst, its preparation method comprises the following steps:

[0033] (1) At room temperature, weigh 1 mmol of copper acetate solid and dissolve it in 40 mL of ethylene glycol to form solution A;

[0034] (2) Weigh 4mmol thiourea and dissolve it in 40mL ethylene glycol to form solution B;

[0035] (3) Mix solution A and solution B evenly, add 1mmol Bi to the mixed solution 2 WO 6 Solid powder, stir evenly;

[0036] (4) 36% acetic acid solution was dripped dropwise into the mixed solution obtained in step (3) under stirring condition, until the pH value of the mixed solution was 5, and continued to stir for 30 min;

[0037] (5) Transfer the mixed solution obtained in step (4) into a 100mL hydrothermal kettle, react at 150°C for 12h, cool naturally to room temperature, alternately wash with deionized water and absolute ethanol, and dry at 80°C to prepare have to.

Embodiment 3

[0039] A CuS / Bi 2 WO 6 Heterojunction photocatalyst, its preparation method comprises the following steps:

[0040] (1) At room temperature, weigh 0.25 mmol of copper acetate solid and dissolve it in 40 mL of ethylene glycol to form solution A;

[0041] (2) Weigh 4mmol thiourea and dissolve it in 40mL ethylene glycol to form solution B;

[0042] (3) Mix solution A and solution B evenly, add 1.5mmol Bi to the mixed solution 2 WO 6 Solid powder, stir evenly;

[0043] (4) 36% acetic acid solution was dripped dropwise into the mixed solution obtained in step (3) under stirring condition, until the pH value of the mixed solution was 6, and continued to stir for 30 min;

[0044] (5) Transfer the mixed solution obtained in step (4) into a 100mL hydrothermal kettle, react at 140°C for 12h, cool naturally to room temperature, alternately wash with deionized water and absolute ethanol, and dry at 80°C to prepare have to.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com