Multi-hole multi-channel auto part washing system

An auto parts and cleaning system technology, applied in the field of parts cleaning, can solve the problems of prolonged hot air preheating, effective removal of surface oil pollution, poor practical application effect, etc., to achieve quality improvement, sealing and safety assurance , the effect of reducing working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the accompanying drawings.

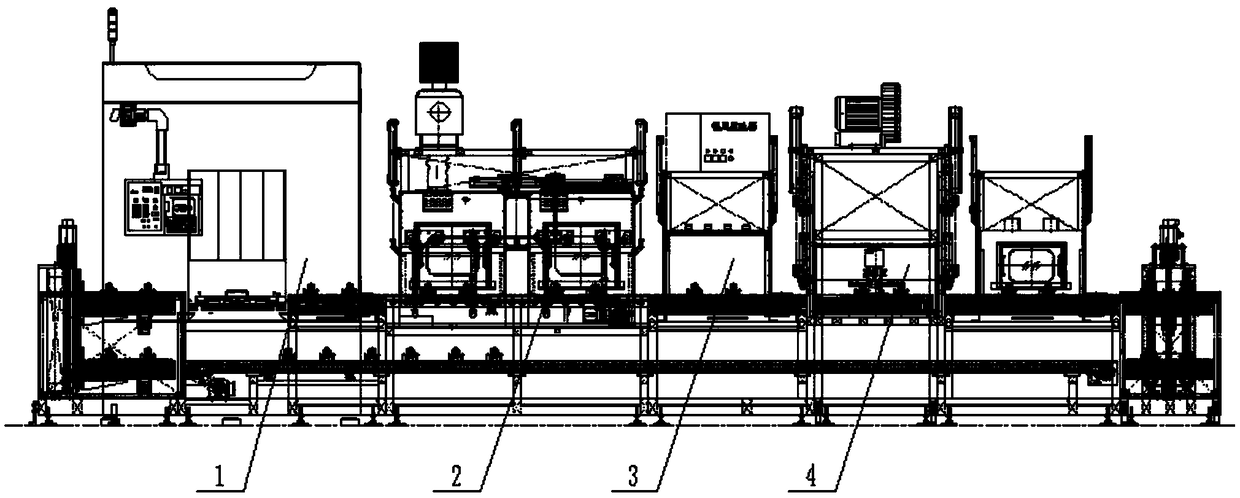

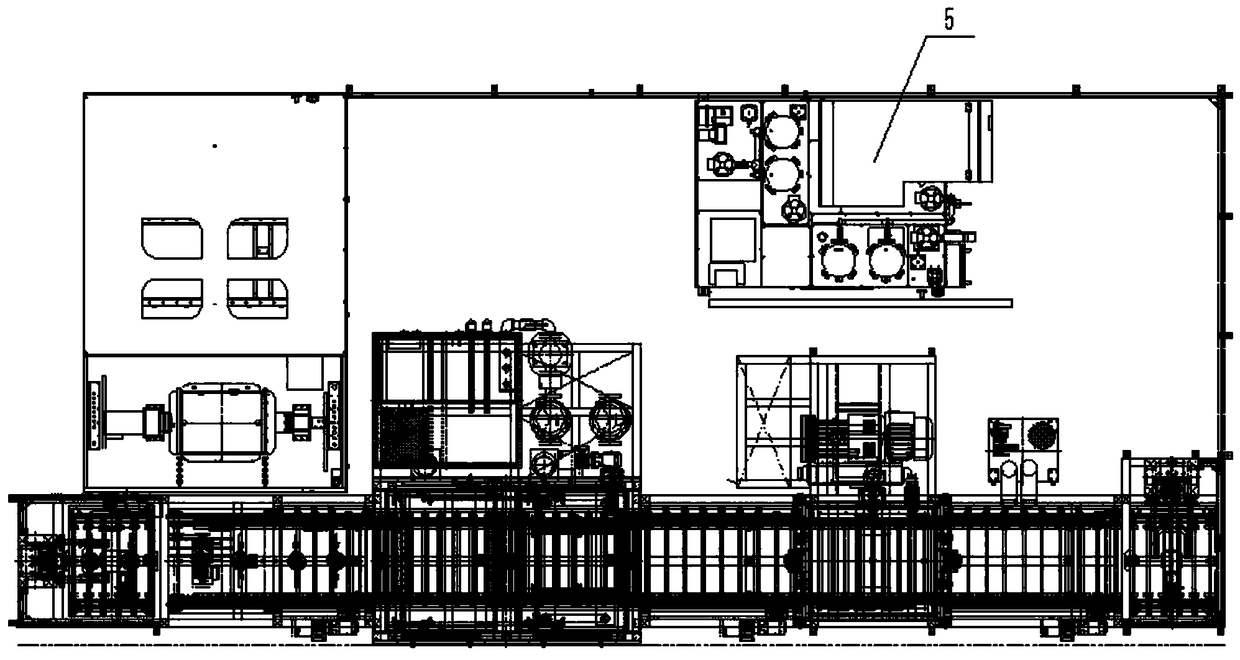

[0023] Such as figure 1 , figure 2 As shown, a porous, multi-channel auto parts cleaning system includes high-pressure cleaning equipment 1, spray wind cutting equipment 2, hot air preheating equipment 3 and vacuum drying equipment 4 in sequence according to the processing procedures;

[0024] High-pressure cleaning equipment 1 uses high-pressure water to clean the burrs and impurities on the outer surface and internal holes and channels of porous and multi-channel auto parts;

[0025] Spray wind cutting equipment 2 uses hot water to spray and rinse sundries and compressed air to cut water to remove most of the water;

[0026] Hot air preheating equipment 3 utilizes hot air to speed up the evaporation of porous, multi-channel residual water on the surface and interior of porous and multi-channel a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com