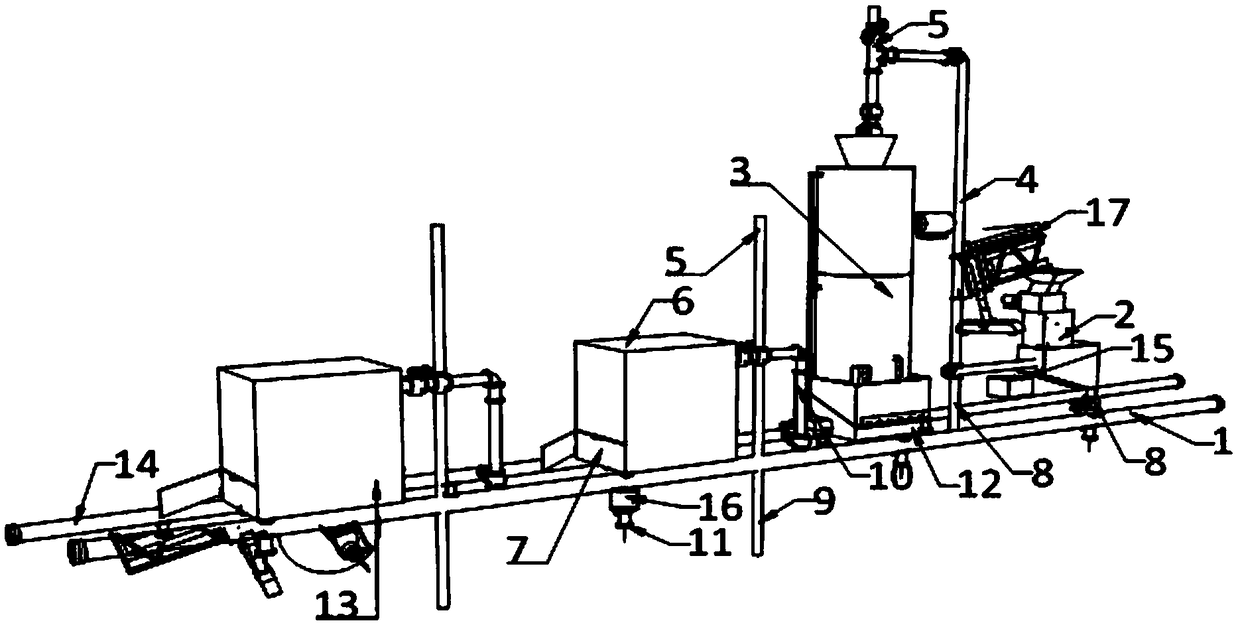

Fresh air humidification and sterilization device in dairy product production wastewater treatment

A sterilizing device and technology for producing wastewater, which is applied in water/sewage treatment, biomass post-treatment, biomass pretreatment, etc., and can solve problems such as complex assembly process, many structural parts, and no sterilizing device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

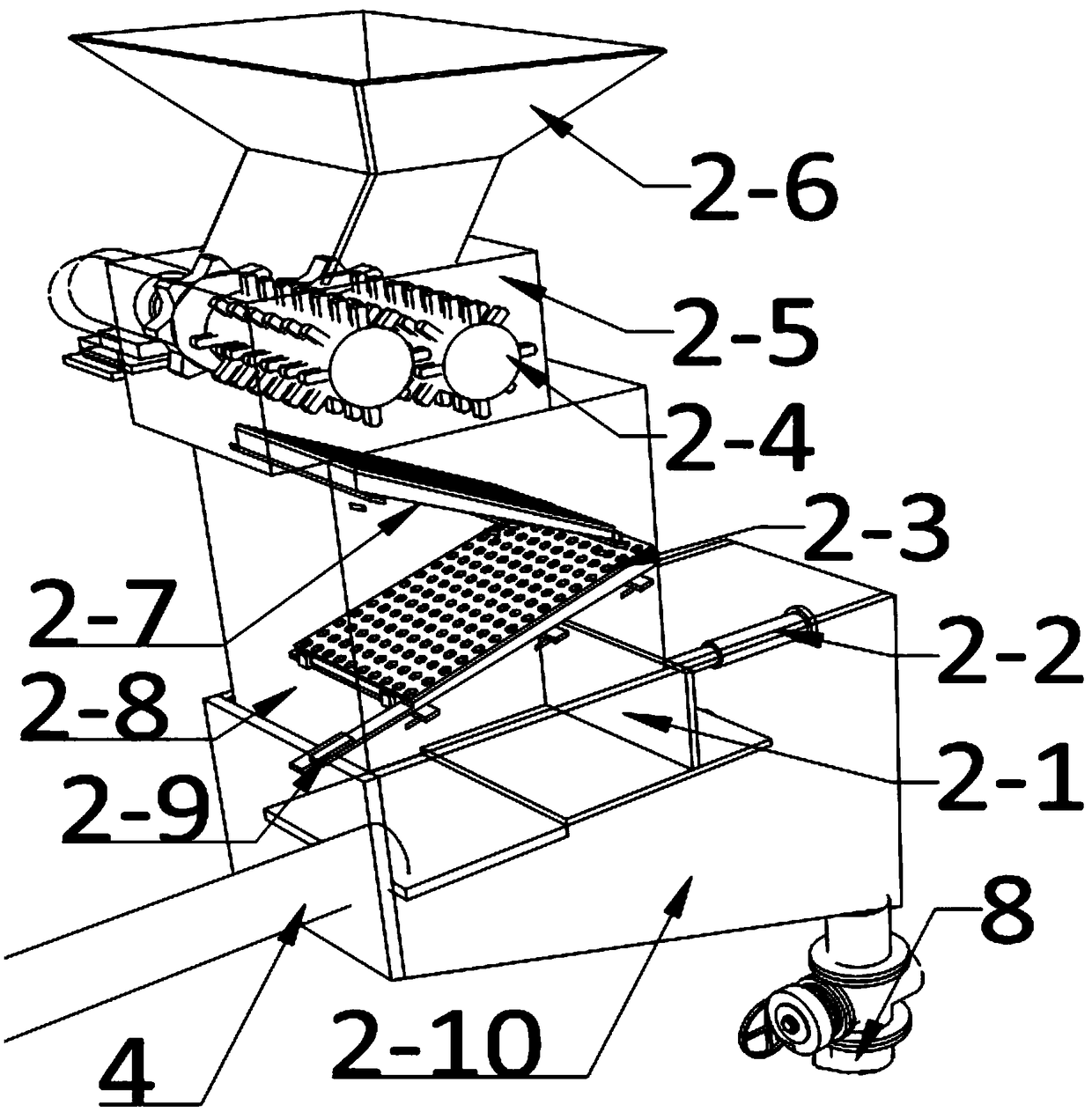

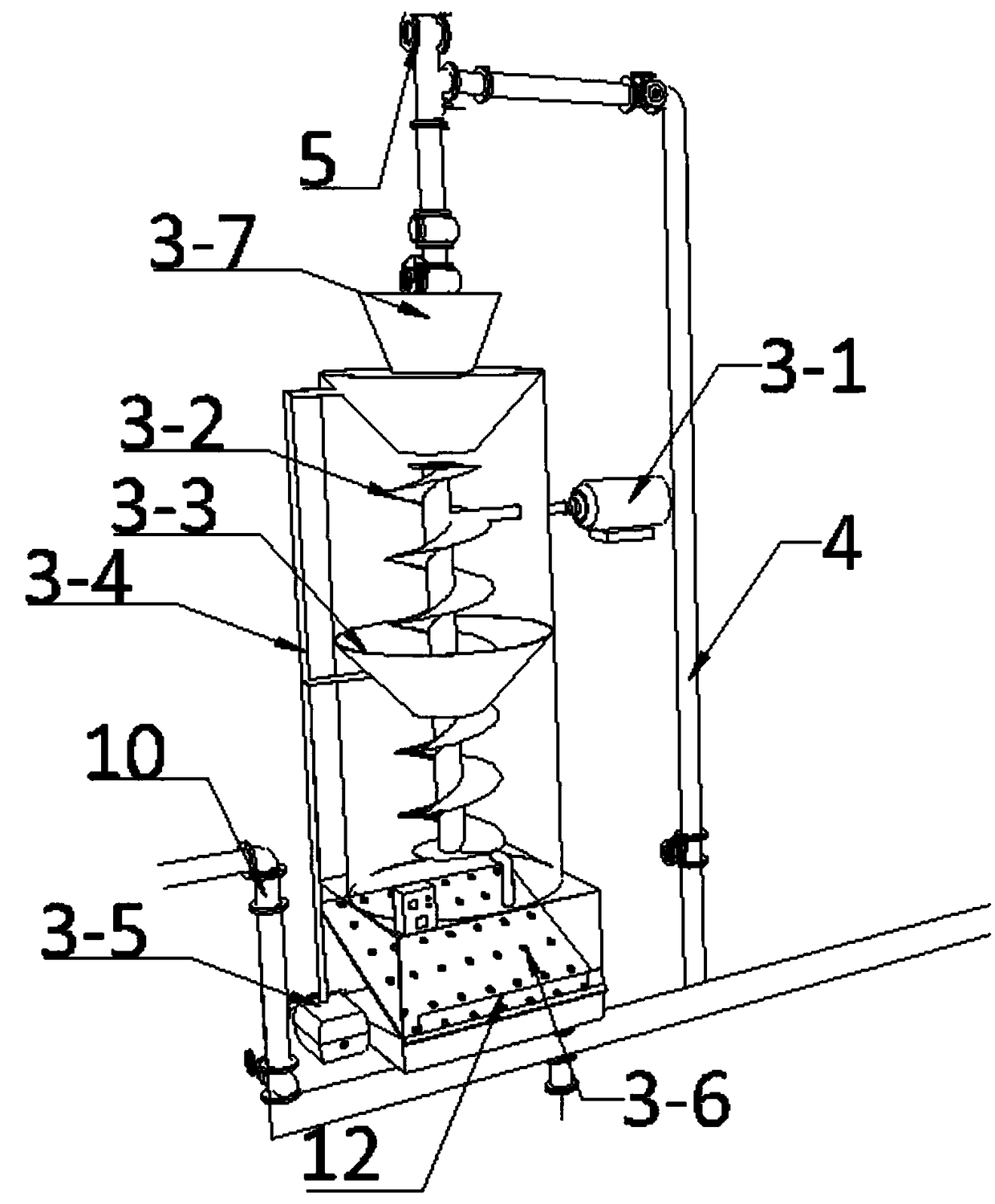

Method used

Image

Examples

Embodiment 1

[0057] Prepare the filtrate plate 3-6 of the present invention according to the following steps, and in parts by weight:

[0058] Step 1: In a twin-shaft stirred reactor, add 268.5 parts of purified water and 3-methyl-4-(2,6,6-trimethyl-1-yl)-3-buten-2-one 60.3 parts, start the mixer in the twin-shaft stirred reactor, set the speed at 61rpm, start the fuel heater in the twin-shaft stirred reactor, make the temperature rise to 76.5°C, add 1-methoxy-3,7 - 63.2 parts of bis[[3-(trimethoxysilyl) propoxy] methyl] end-capped poly(silane) were stirred evenly, and the reaction was carried out for 53.3 minutes, and 59.2 parts of methylvinyl dichlorosilane were added, and the flow rate was 52.5m 3 Nitrogen per min for 53.3 minutes; then add 62.6 parts of collagen powder to the biaxial stirred reactor, start the fuel heater in the biaxial stirred reactor again, raise the temperature to 93.2°C, keep warm for 53.2 minutes, add methyl 65.2 parts of tetrahydrophthalic anhydride, adjust the...

Embodiment 2

[0064] Prepare the filtrate plate 3-6 of the present invention according to the following steps, and in parts by weight:

[0065] Step 1: In a twin-shaft stirred reactor, add 493.0 parts of purified water and 3-methyl-4-(2,6,6-trimethyl-1-yl)-3-buten-2-one 102.7 parts, start the mixer in the twin-shaft stirred reactor, set the speed at 107rpm, start the fuel oil heater in the double-shaft stirred reactor, make the temperature rise to 77.0°C, add 1-methoxy-3,7 - 172.2 parts of bis[[3-(trimethoxysilyl) propoxy] methyl] end-capped poly(silane) and stirred evenly, reacted for 64.7 minutes, added 76.0 parts of methylvinyl dichlorosilane, and the flow rate was 93.0m 3 / min of nitrogen for 64.7 minutes; then add 119.1 parts of collagen powder to the twin-shaft stirred reactor, start the fuel heater in the twin-shaft stirred reactor again, raise the temperature to 126.2°C, keep warm for 64.0 minutes, add methyl 126.5 parts of tetrahydrophthalic anhydride, adjust the pH value of the ...

Embodiment 3

[0071] Prepare the filtrate plate 3-6 of the present invention according to the following steps, and in parts by weight:

[0072] Step 1: Add 268.9 parts of purified water and 3-methyl-4-(2,6,6-trimethyl-1-yl)-3-buten-2-one to the twin-shaft stirred reactor 60.9 parts, start the mixer in the twin-shaft stirred reactor, set the speed at 61rpm, start the fuel heater in the double-shaft stirred reactor, make the temperature rise to 76.9 ° C, add 1-methoxy-3,7 - 63.9 parts of bis[[3-(trimethoxysilyl) propoxy] methyl] end-capped poly(silane) were stirred evenly, and the reaction was carried out for 53.9 minutes, and 59.9 parts of methyl vinyl dichlorosilane were added, and the flow rate was 52.9m 3 Nitrogen per min for 53.9 minutes; then add 62.9 parts of collagen powder to the biaxial stirred reactor, start the fuel heater in the biaxial stirred reactor again, raise the temperature to 93.9°C, keep warm for 53.9 minutes, add methyl 65.9 parts of tetrahydrophthalic anhydride, adju...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com