A kind of degradable low-temperature co-fired ceramics and its preparation method

A technology of low temperature co-fired ceramics and ceramics, applied in the field of electronic engineering applications, can solve problems such as environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

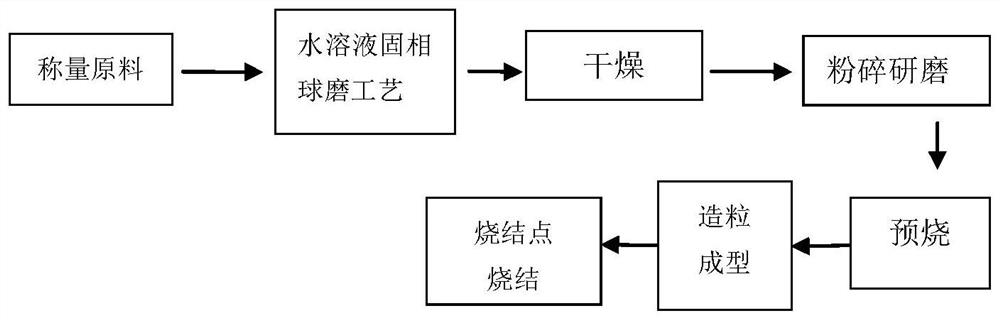

[0025] Such as figure 1 Shown, a kind of preparation method of above-mentioned degradable low-temperature co-fired ceramics, comprises the following steps:

[0026] S1, with SiO 2 , SiO 2 ·nH 2 O, H 3 BO 3 , B 2 o 3 , NaOH, KOH, Ba(OH) 2 ·8H 2 O, Al(OH) 3 , MgO, CaO, SrO, ZnO and rare earth oxides as raw materials, according to the composition of ceramics, weigh each raw material separately, and add distilled water according to the water-solid ratio of 3 to 5:1 to make a mixture, and set aside;

[0027] S2. Using a ball mill to mill the water-solid mixture in step S1, the milling time is 5 to 7 hours;

[0028] S3. After the treatment in step S2, the ceramic suspension slurry is separated, and dried at a temperature of 80-100° C. to a constant weight for 24-36 hours to obtain a dry sample;

[0029] S4, taking out the dry sample and crushing and grinding to obtain a powdery material with a particle size of 2-50 μm;

[0030] S5, placing the powdery material in a cruc...

Embodiment 1

[0034] A method for preparing the above-mentioned degradable low-temperature co-fired ceramics, comprising the following steps:

[0035] S1, with SiO 2 、H 3 BO 3 , Al(OH) 3 as raw material, according to xB 2 o 3 ·ySiO 2 · zAl 2 o 3 In wMO, x=23%, y=64%, z=13%, w=0% ratio, weigh each raw material separately, and add distilled water according to the water-solid ratio of 3-5:1 to make a mixture, set aside ;

[0036] S2. Use a ball mill to mill the water-solid mixture in step S1, and the milling time is 6 hours;

[0037] S3. After the treatment in step S2, the ceramic suspension slurry is separated, and dried at a temperature of 90° C. to a constant weight for 30 hours to obtain a dry sample;

[0038] S4, taking out the dry sample and crushing and grinding to obtain a powdery material with a particle size of 2-50 μm;

[0039] S5, placing the powdery material in a crucible, and calcining at a temperature of 300° C. for 5 hours to obtain a pre-calcined sample;

[0040] S6,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com