Multifunctional self-repairing adhesive for lithium-sulfur battery positive electrode, preparation method and application thereof

A lithium-sulfur battery, multi-functional technology, applied in the direction of battery electrodes, lithium batteries, positive electrodes, etc., can solve the problems of limited ability to adsorb polysulfide compounds, poor toughness of polyacrylic acid, etc., to protect the integrity of the interface and ensure the conductive path , the effect of excellent cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0069] Preparation of Sulfur / Carbon Black Composite: Sulfur Loading of Commercial Super p Carbon Materials Using In Situ Generation. The specific operation is: put 3.0g of Na 2 S 2 o 3 ·5H 2 O and 0.15g of Super p carbon material were placed in a 50mL round-bottomed flask, and 10mL of deionized water was added, stirred for 10min until uniform and ready for use. Measure the concentrated hydrochloric acid (38wt%) of 2.37g again, after adding 23.7g deionized water and fully mixing, dilute hydrochloric acid is slowly dripped in the above-mentioned round bottom flask, after stirring and reacting for 12h, the reaction system is carried out suction filtration, washing to The filtrate was neutral, and the product was dried in a blast oven at 60°C, and then dried for use.

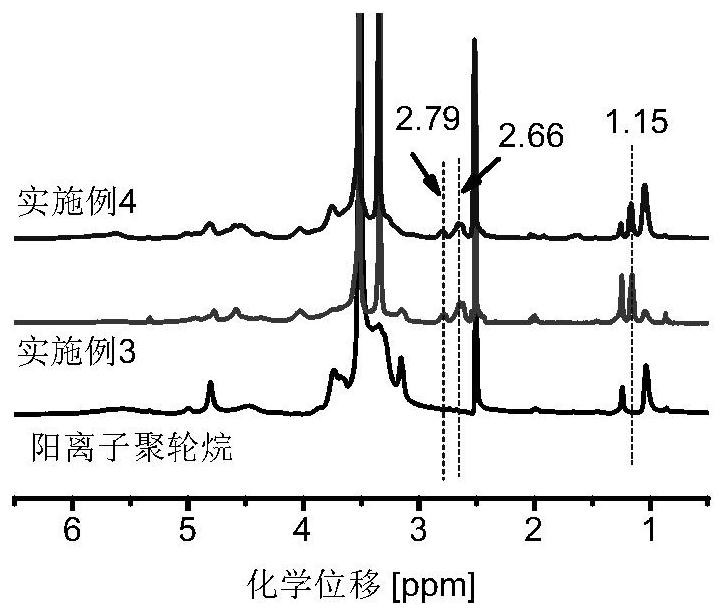

[0070] Polyrotaxane is a polymer material prepared by α-cyclodextrin and polyethylene glycol through supramolecular self-assembly-capping method. The cationic polyrotaxane is a polymer material obtained by reac...

Embodiment 1

[0072] The preparation of embodiment 1 phenylboronic acid graft polyacrylic acid

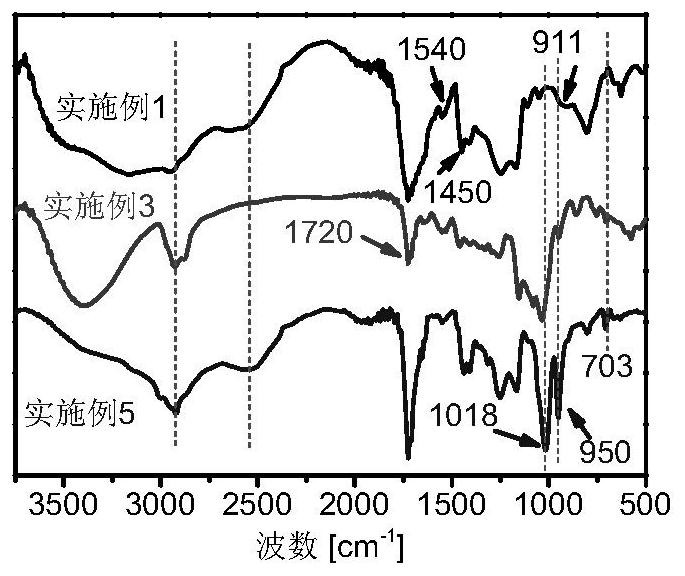

[0073] Weigh 1.0g of dried polyacrylic acid (number average molecular weight 400kDa) and add it to 20mL of dimethylformamide (DMF). After stirring to obtain a clear solution, add 5mL of DMF solution containing 0.06g of N,N-dicarbonylimidazole , stirred and reacted at 50°C in an argon atmosphere for 12h, cooled to 30°C and added 0.086g of 3-aminophenylboronic acid, kept the temperature for 48h, concentrated and dripped into excess tetrahydrofuran (THF) for precipitation, separated by Vacuum drying to obtain phenylboronic acid grafted polyacrylic acid. Infrared spectrogram see attached figure 1 , where at 1540cm -1 and 1450cm -1 The absorption peak that appears comes from the skeleton vibration of C=C in the benzene ring, at 911cm -1 The C-H out-of-plane bending vibration signal in the benzene ring structure appeared at , indicating the successful preparation of phenylboronic acid grafted poly...

Embodiment 2

[0074] The preparation of embodiment 2 phenylboronic acid graft polyacrylic acid

[0075] Weigh 1.0g of dried polyacrylic acid (number average molecular weight 400kDa) and add it to 20mL of dimethylformamide (DMF). After stirring to obtain a clear solution, add 5mL of DMF solution containing 0.3g of N,N-dicarbonylimidazole , stirred and reacted at 50°C in an argon atmosphere for 12h, cooled to 30°C and added 0.086g of 3-aminophenylboronic acid, kept the temperature for 48h, concentrated and dripped into excess tetrahydrofuran (THF) for precipitation, separated by Vacuum drying to obtain phenylboronic acid grafted polyacrylic acid. In this embodiment, the grafting rate of phenylboronic acid grafted polyacrylic acid is 13.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| number average molecular weight | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com