Heat-conducting nylon material as well as preparation method and application thereof

A nylon and branched nylon technology, applied in the field of polymer materials, can solve the problems of inability to take into account the comprehensive requirements of heat dissipation and mechanical properties, difficulty in meeting the heat dissipation requirements of electronic products, and poor impact resistance of thermally conductive nylon plastics. Flammability, high bending performance, the effect of improving physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

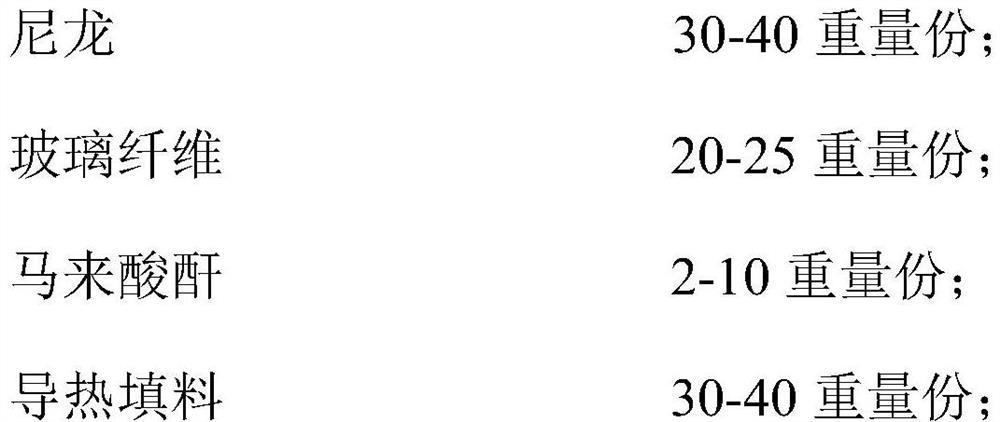

[0040] This embodiment provides a thermally conductive nylon material, including the following components by weight:

[0041]

[0042] The nylon is a combination of branched nylon 6 and nylon 12 with a mass ratio of 7:3, wherein the relative viscosity of branched nylon 6 is 3.60, which is 3200H of Baling Petrochemical, and nylon 12 is purchased from Baling Petrochemical; The filler is a combination of aluminum nitride and silicon carbide at a mass ratio of 3:2.

[0043] The preparation method of the heat-conducting nylon material comprises the following steps:

[0044] (1) Mix branched nylon 6, nylon 12 and maleic anhydride for 10 minutes under stirring to obtain mixture A;

[0045] (2) Add a thermally conductive filler to the mixture A obtained in step (1), and mix for 15 minutes under stirring to obtain a mixture B;

[0046] (3) Add glass fiber (average diameter of 20 μm, dried after immersion in silane coupling agent KH550) and titanium dioxide to the mixture B obtaine...

Embodiment 2

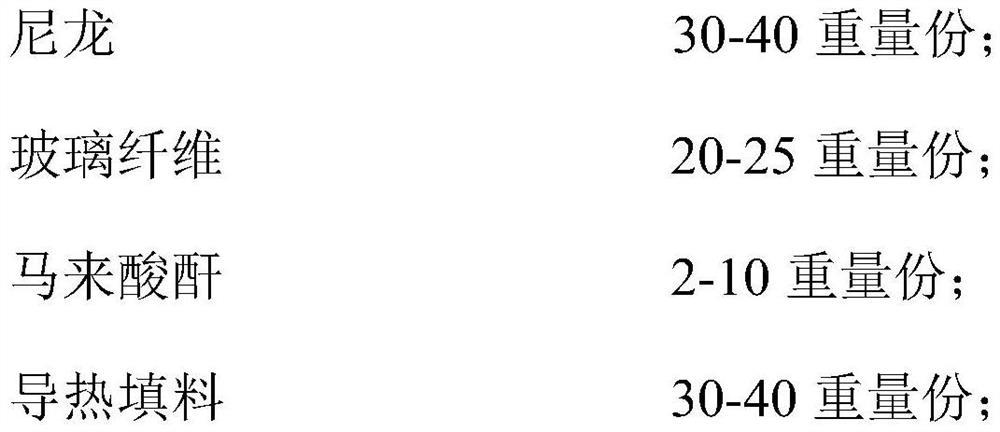

[0048] This embodiment provides a thermally conductive nylon material, including the following components by weight:

[0049]

[0050] The nylon is a combination of branched nylon 6 and nylon 12 at a mass ratio of 2.5:1; the thermally conductive filler is a combination of zinc oxide, magnesium oxide, aluminum oxide, and aluminum hydroxide at a mass ratio of 1:1:1.5:1.5.

[0051] The preparation method of the heat-conducting nylon material comprises the following steps:

[0052] (1) Mix branched nylon 6, nylon 12 and maleic anhydride for 5 minutes under stirring to obtain mixture A;

[0053] (2) Add a thermally conductive filler to the mixture A obtained in step (1), and mix for 10 minutes under stirring conditions to obtain a mixture B;

[0054] (3) Add glass fiber (with an average diameter of 20 μm, dried after being soaked in silane coupling agent KH550) and titanium dioxide to the mixture B obtained in step (2), mix for 5 minutes under agitation, and then use a twin-scr...

Embodiment 3

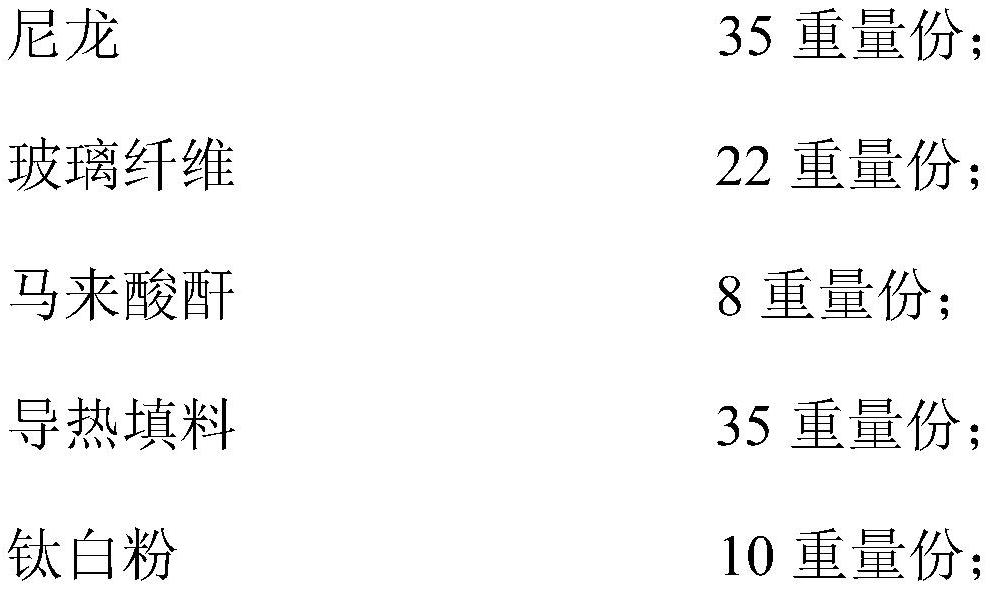

[0056] This embodiment provides a thermally conductive nylon material, including the following components by weight:

[0057]

[0058] The nylon is a combination of branched nylon 6 and nylon 12 in a mass ratio of 2:1; the thermally conductive filler is zinc nitride, aluminum nitride, silicon carbide, and magnesium hydroxide in a mass ratio of 1:2:1:1 The combination.

[0059] The preparation method of the heat-conducting nylon material comprises the following steps:

[0060] (1) Mix branched nylon 6, nylon 12 and maleic anhydride for 15 minutes under stirring to obtain mixture A;

[0061] (2) Add a thermally conductive filler to the mixture A obtained in step (1), and mix for 20 minutes under stirring conditions to obtain a mixture B;

[0062] (3) Add glass fiber (average diameter is 15 μ m, dry after soaking through silane coupling agent KH550) and titanium dioxide in the mixture B that step (2) obtains, mix 15min under agitation condition, then adopt extruder at 195 U...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com