Polyethyleneimine functionalized inorganic particle/brominated polyphenylene ether hybrid ultrafiltration membrane and preparation method thereof

A technology of polyethyleneimine and brominated polyphenylene ether, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of weak force and limited improvement of membrane performance, and achieve low production cost , easy batch production, and excellent pollution recovery performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

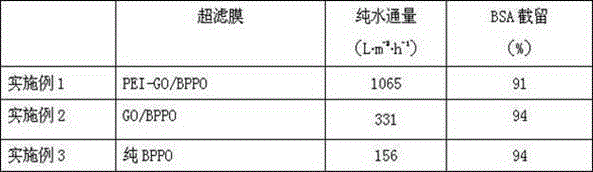

Embodiment 1

[0018] First, prepare polyethyleneimine functionalized graphene oxide, disperse 0.06 parts by weight of modified graphene oxide in 20% (w / w) BPPO / NMP solution (10 parts by weight of brominated polyphenylene ether are dispersed in 37 parts by weight of N-methyl-2-pyrrolidone), stirring, ultrasonication, standing and degassing, coating the casting solution on a clean glass plate, and then placing the glass plate horizontally at 30 o C in the coagulation bath (water bath) for 2 hours. Finally, wash the prepared membrane with a large amount of deionized water to remove the residual solvent in the membrane, and store it in water. The obtained membrane is a PEI-GO / BPPO hybrid ultrafiltration membrane.

[0019] Under the operating pressure of 0.2MPa, the PEI-GO / BPPO hybrid ultrafiltration membrane has a rejection rate of 91% for bovine serum albumin aqueous solution with a concentration of 0.5g / L and a pure water flux of 1065L m -2 h -1 .

[0020] With embodiment 1, the unmodified...

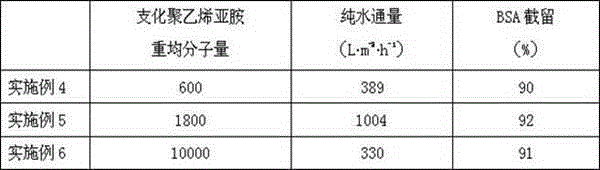

Embodiment 4-6

[0025] As in Example 1, different modified graphene oxide particles were prepared with branched polyethyleneimines with different weight average molecular weights (Mw=600, 1800 and 10000), respectively PEI(600)-GO, PEI(1800) -GO, PEI(10000)-GO, and then disperse 0.06 parts by mass of PEI-GO into 20% (w / w) BPPO / NMP (10 parts by weight of brominated polyphenylene ether dispersed in 37 parts by weight of N-methyl Base-2-pyrrolidone), stirring, ultrasonication, standing and defoaming, and finally phase inversion to obtain PEI-GO / BPPO hybrid ultrafiltration membranes containing polyethyleneimine modified graphene oxide with different molecular weights. They are PEI(600)-GO / BPPO, PEI(1800)-GO / BPPO, PEI(10000)-GO / BPPO hybrid ultrafiltration membranes.

[0026] These several examples are to investigate the influence of polyethyleneimine with different molecular weight on the performance of polyethyleneimine functionalized graphene oxide / brominated polyphenylene ether hybrid ultrafiltr...

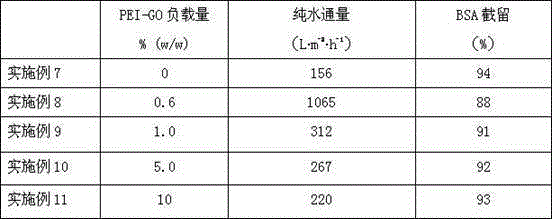

Embodiment 7-11

[0030] With embodiment 1, the unmodified graphene oxide of 0~1 mass part is dispersed in 20% (w / w) BPPO / NMP solution (the brominated polyphenylene ether of 10 weight parts is dispersed in the N- Methyl-2-pyrrolidone), stirring, ultrasonication, standing and defoaming, and finally phase inversion to obtain PEI-GO / BPPO hybrid ultrafiltration membranes with different loadings of modified particles.

[0031] These several examples are to investigate the effect of different PEI-GO loadings on the performance of the prepared hybrid ultrafiltration membrane. The pure water flux under the pressure of 0.2MPa and the interception test results of BSA at pH=4.7 and 0.5mg / L are as follows:

[0032]

[0033] It can be seen from Examples 7-11 that the flux of 0.6% (w / w) PEI-GO / BPPO hybrid ultrafiltration membrane is the largest, which is 2 to 7 times that of other membranes, and the interception of protein is very small.

[0034]It can be seen that lower addition amount can realize the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com