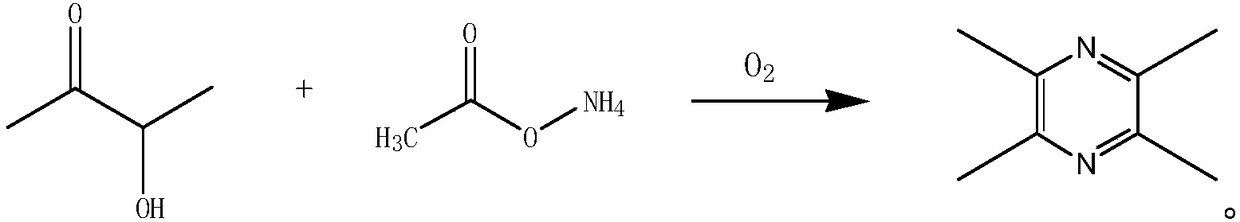

Synthesis method and device of 2,3,5,6-tetramethylpyrazine

A technology of tetramethylpyrazine and synthetic methods, applied in the direction of organic chemistry, etc., can solve the problems of high operating conditions, high production costs, and difficulty in separation, and achieve the effects of low raw material cost, high yield, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

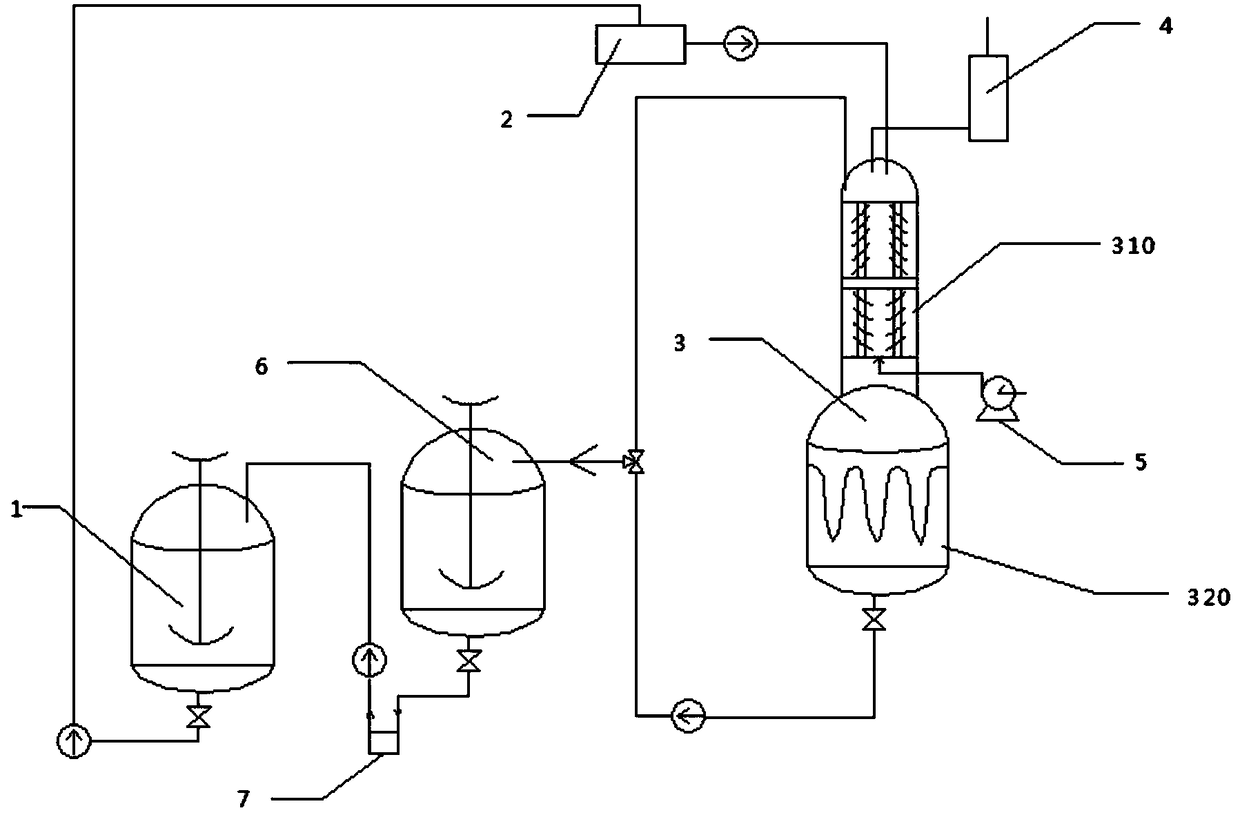

[0055] Prepare the pipeline reactor, condenser, metering pump and reaction kettle equipped with elevated tank and bubbling device;

[0056] Heat the reactor water bath to 80°C, prepare a mixed aqueous solution of acetoin, ammonium acetate and sodium acetate, and add it to the batching kettle; the molar ratio of acetoin and ammonium acetate is 1:1.15;

[0057] Use the metering pump to transfer the reaction liquid to the head tank, and then enter the radial adiabatic fixed bed reactor through the metering pump in the head tank;

[0058] The temperature of the water bath is raised to 80°C, and at the same time, the bubbler is turned on, and the air is blown into the pipeline for reaction. When the content of 2,3,5,6-tetramethylpyrazine in the material reaches the preset value, the material is transferred to the neutralization Carry out post-processing in the freezer;

[0059] The post-treated material is separated by a centrifugal separation device to recover the solid product, ...

Embodiment 2

[0063] Prepare the pipeline reactor equipped with elevated tank and bubbling device, condenser, metering pump and reactor;

[0064] Heat the reactor water bath to 80°C, prepare a mixed aqueous solution of acetoin, ammonium acetate and sodium acetate, and add it to the batching kettle; the molar ratio of acetoin and ammonium acetate is 1:1.2;

[0065] Use the metering pump to transfer the reaction liquid to the head tank, and then enter the radial adiabatic fixed bed reactor through the metering pump in the head tank;

[0066] The temperature of the water bath is raised to 80°C, and at the same time, the bubbler is turned on, and the air is blown into the pipeline for reaction. When the content of 2,3,5,6-tetramethylpyrazine in the material reaches the preset value, the material is transferred to the neutralization Carry out post-processing in the freezer;

[0067] The post-treated material is separated by a centrifugal separation device to recover the solid product, and the c...

Embodiment 3

[0071] Prepare the pipeline reactor, condenser, metering pump and reaction kettle equipped with elevated tank and bubbling device;

[0072] Heat the reactor water bath to 80°C, prepare a mixed aqueous solution of acetoin, ammonium acetate and sodium acetate, and add it to the batching kettle; the molar ratio of acetoin and ammonium acetate is 1:1.18;

[0073] Use the metering pump to transfer the reaction liquid to the head tank, and then enter the radial adiabatic fixed bed reactor through the metering pump in the head tank;

[0074] The temperature of the water bath is raised to 80°C, and at the same time, the bubbler is turned on, and the air is blown into the pipeline for reaction. When the content of 2,3,5,6-tetramethylpyrazine in the material reaches the preset value, the material is transferred to the neutralization Carry out post-processing in the freezer;

[0075] The post-treated material is separated by a centrifugal separation device to recover the solid product, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap