Enclosure for bracelet monitoring vital signs and preparation method of enclosure

A vital sign and shell technology, which is applied to the shell of a vital sign monitoring wristband and the field of its preparation, can solve the problems of cracking, easy fracture, easy wear and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

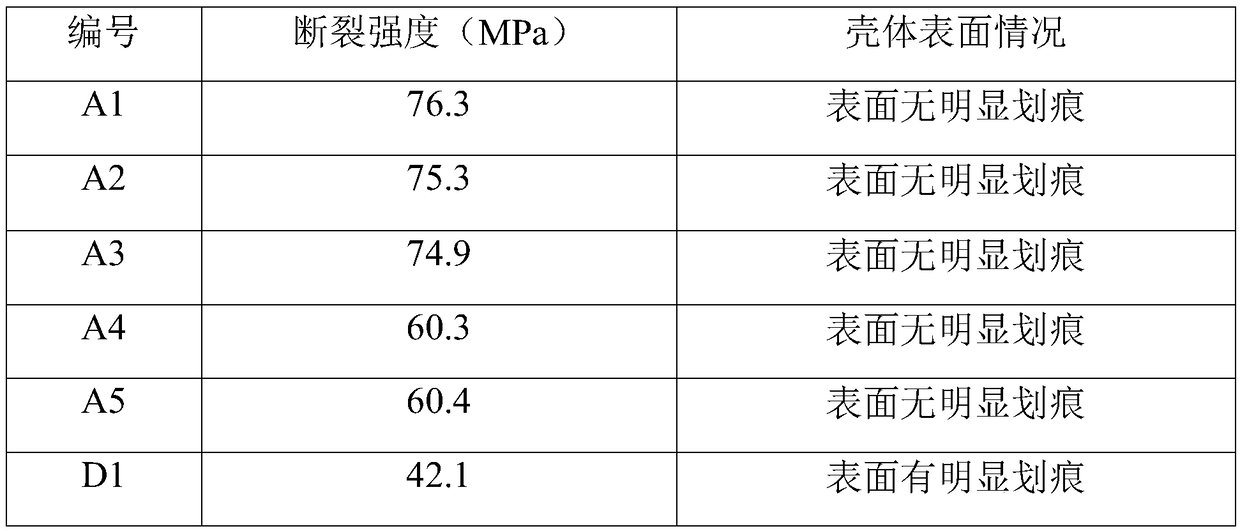

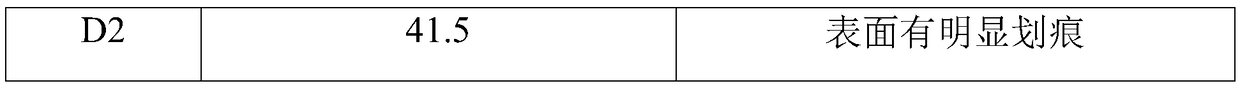

Examples

preparation example Construction

[0013] The invention provides a method for preparing a shell of a vital sign monitoring bracelet, wherein the preparation method comprises: polypropylene, polyphenylene sulfide, acrylate oligomers, polyethylene wax, emulsifier After mixing with the stabilizer, extruding and granulating to obtain masterbatch M; mixing the masterbatch M, glass fiber and sodium dodecylbenzenesulfonate, and extruding to obtain the shell, wherein, extruding The molding is carried out in a twin-screw extruder. The temperature of the feeding zone in the twin-screw extruder is: 110-130°C; the temperature of the melting zone: 170-200°C; the temperature of the mixing zone: 210-230°C; The temperature in the pressure build-up zone is 220-245°C; relative to 100 parts by weight of polypropionic acid, the amount of polyphenylene sulfide is 50-70 parts by weight, the amount of acrylate oligomers is 20-28 parts by weight, polyethylene The consumption of wax is 30-55 parts by weight, the consumption of emulsifi...

Embodiment 1

[0020] After mixing 100g polypropylene, 55g polyphenylene sulfide, 22g acrylate oligomer, 40g polyethylene wax, 4g octylphenol polyoxyethylene ether and 1g lead nitrate, extrude and granulate to obtain masterbatch M; Masterbatch M, 30g glass fiber and 20g sodium dodecylbenzene sulfonate are mixed and extruded to obtain shell A1, wherein the extrusion molding is carried out in a twin-screw extruder, and the feeding in the twin-screw extruder Zone temperature: 110°C; melting zone temperature: 170°C; kneading zone temperature: 210°C; pressure building zone temperature: 220°C.

Embodiment 2

[0022] After mixing 100g polypropylene, 65g polyphenylene sulfide, 26g acrylate oligomer, 50g polyethylene wax, 6g benzyldimethylphenol polyoxyethylene ether and 1.2g lead sulfate, extrude and granulate to obtain the mother Granule M; masterbatch M, 35g glass fiber and 25g sodium dodecylbenzene sulfonate are mixed, and the shell A2 is obtained through extrusion molding, wherein, the extrusion molding is carried out in a twin-screw extruder, and the twin-screw extrusion The temperature of the feeding zone in the machine is 130°C; the temperature of the melting zone is 200°C; the temperature of the kneading zone is 230°C; the temperature of the pressure building zone is 245°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com