Phase-change material for fabric based on microporous membrane, yarn, fabric and wearings

A phase change material and microporous technology, which is applied in the field of phase change materials, yarns, fabrics and wearables, can solve the problem that the core paraffin hydrocarbon phase change heat cannot be transmitted well, the heat transfer effect is poor, and energy waste, etc. problem, to achieve the effect of not easily soluble in water, high utilization rate and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

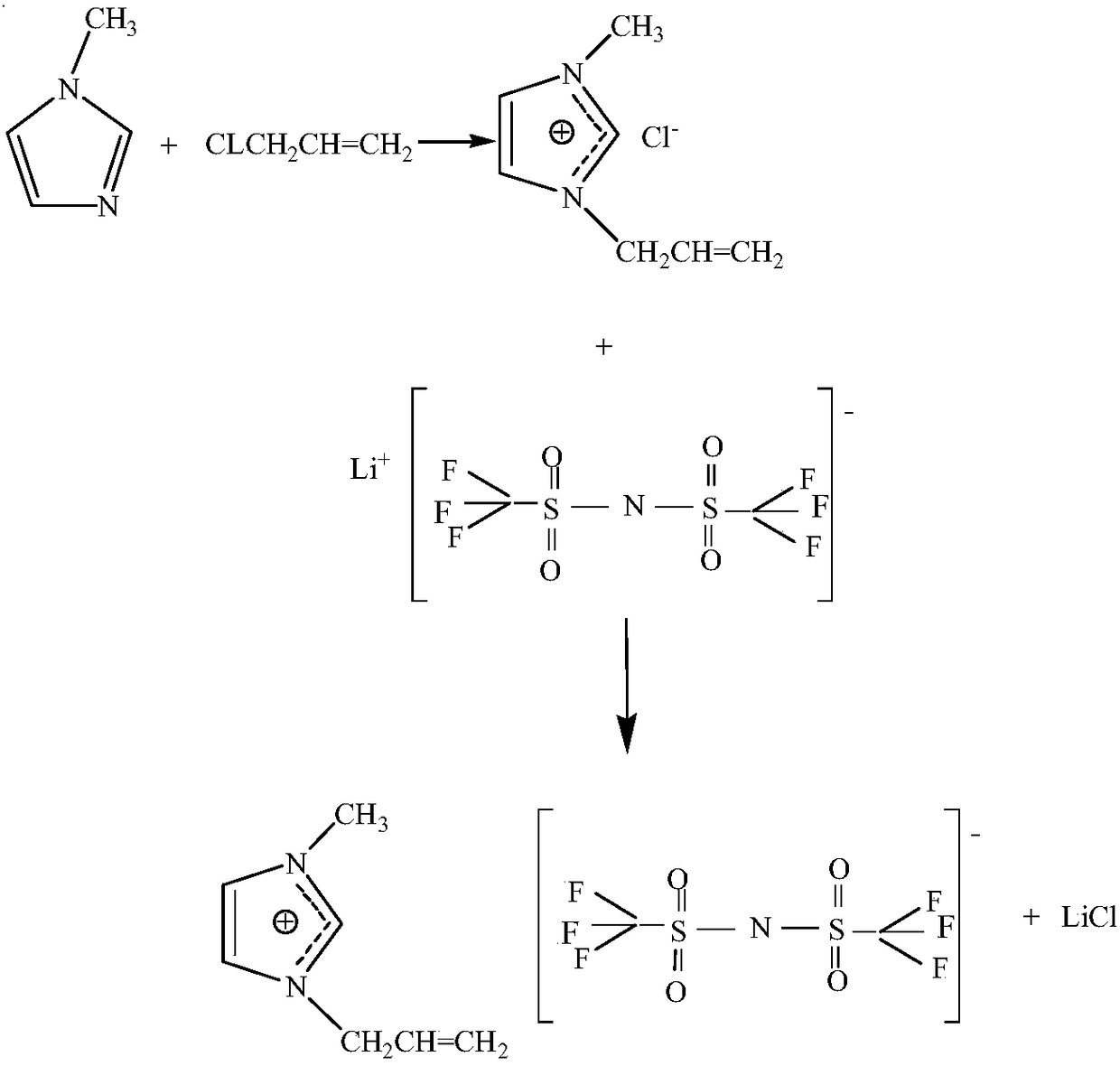

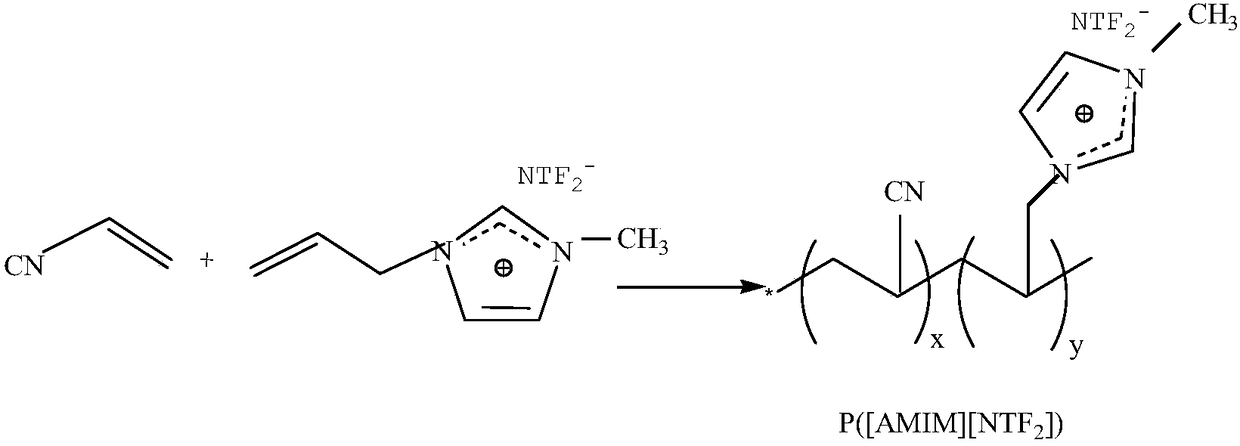

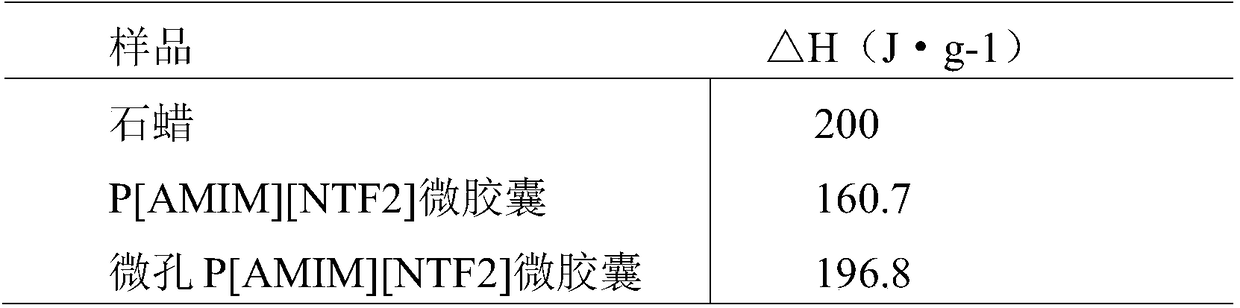

Method used

Image

Examples

Embodiment 1

[0027] The microporous phase change material used for fabrics is a microporous microcapsule composed of a shell material and a core material, the shell material is a microporous polymer ion liquid polymer membrane, and the core material includes a phase change material.

[0028] Wherein, the microporous polymer ionic liquid polymer membrane is a microporous ionic liquid polymer membrane. The phase change temperature of the phase change material of the core is between 0°C and 50°C, and the phase change material is inorganic salt hydrate, polyethylene glycol, long straight chain alkanes, paraffins, medium and long straight chain alkanes, stearin One or more of the acid esters. The cations in the ionic liquid in the microporous polymer ionic liquid polymer film are N, N'-dialkylimidazolium cations, alkyl ammonium cations, alkyl quaternary phosphine cations, N-alkylpyridinium cations or guanidine salts Cation, the anion in the ionic liquid in the microporous polymer ionic liquid ...

Embodiment 2

[0050] The microporous phase change material used for fabrics is a microporous microcapsule composed of a shell material and a core material, the shell material is a microporous polymer ion liquid polymer membrane, and the core material includes a phase change material.

[0051] Wherein, the microporous high molecular ionic liquid polymer membrane is a microporous ionic liquid-high molecular polymer composite membrane. The phase change temperature of the phase change material of the core is between 0°C and 50°C, and the phase change material is inorganic salt hydrate, polyethylene glycol, long straight chain alkanes, paraffins, medium and long straight chain alkanes, stearin One or more of the acid esters. The cations in the ionic liquid in the microporous polymer ionic liquid polymer film are N, N'-dialkylimidazolium cations, alkyl ammonium cations, alkyl quaternary phosphine cations, N-alkylpyridinium cations or guanidine salts Cation, the anion in the ionic liquid in the m...

Embodiment 3

[0074] The microporous phase change material used for fabrics is a microporous microcapsule composed of a shell material and a core material, the shell material is a microporous polymer ion liquid polymer membrane, and the core material includes a phase change material.

[0075] Wherein, the microporous polymer ion liquid polymer membrane is a microporous polyionic liquid functional polymer membrane. The phase change temperature of the phase change material of the core is between 0°C and 50°C, and the phase change material is inorganic salt hydrate, polyethylene glycol, long straight chain alkanes, paraffins, medium and long straight chain alkanes, stearin One or more of the acid esters. The cations in the ionic liquid in the microporous polymer ionic liquid polymer film are N, N'-dialkylimidazolium cations, alkyl ammonium cations, alkyl quaternary phosphine cations, N-alkylpyridinium cations or guanidine salts Cation, the anion in the ionic liquid in the microporous polymer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com