Surfactant with low surface and interface tension and high contact angle and preparation method thereof

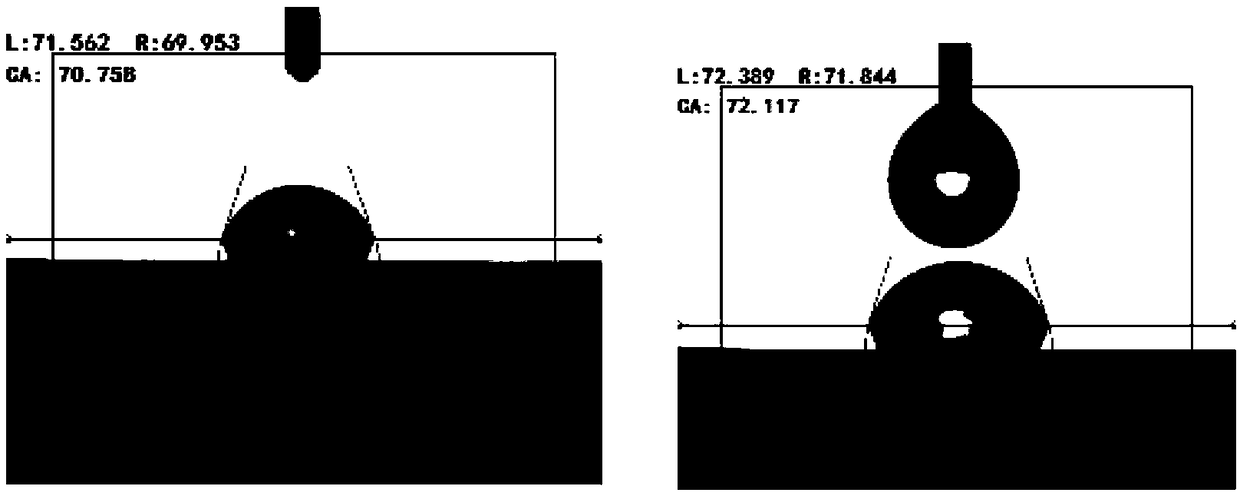

A surfactant and co-surfactant technology, which is applied in the field of low surface interfacial tension and high contact angle oilfield chemical additives and its preparation, can solve the problem of single well productivity decline, high development cost, and low permeability reservoirs Poor permeability and other problems, to achieve low interfacial tension and reduce the effect of oil-water interfacial tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] This embodiment provides a low surface and interfacial tension high contact angle surfactant, which comprises the following components in parts by weight: 20 parts of perfluoroalkyl polyoxyethylene ether, 50 parts of OP-10, polyallyl trimethyl 50 parts of ammonium chloride, 50 parts of methanol.

[0024] The preparation method of the low surface interfacial tension high contact angle surfactant of the present embodiment comprises the following steps:

[0025] Take polyallyltrimethylammonium chloride polymer and add co-surfactant, stir evenly, add perfluoroalkyl polyoxyethylene ether, OP-10 and continue stirring, then add 50 parts by weight of water and stir until uniform, that is have to.

Embodiment 2

[0027] This embodiment provides a low surface and interfacial tension high contact angle surfactant, which comprises the following components in parts by weight: 15 parts of perfluoroalkyl polyoxyethylene ether, 60 parts of OP-10, polyallyl trimethyl 40 parts of ammonium chloride, 60 parts of ethanol.

[0028] The preparation method of the low surface interfacial tension high contact angle surfactant of the present embodiment comprises the following steps:

[0029] Take polyallyltrimethylammonium chloride polymer and add co-surfactant, stir evenly, add perfluoroalkyl polyoxyethylene ether, OP-10 and continue stirring, then add 40 parts by weight of water and stir until uniform, that is have to.

Embodiment 3

[0031] This embodiment provides a low surface and interfacial tension high contact angle surfactant, which comprises the following components in parts by weight: 25 parts of perfluoroalkyl polyoxyethylene ether, 40 parts of OP-10, polyquaternium-7 60 parts, 40 parts of n-propanol.

[0032] The preparation method of the low surface interfacial tension high contact angle surfactant of the present embodiment comprises the following steps:

[0033] Take polyquaternium-7 high polymer, add co-surfactant, stir evenly, add perfluoroalkyl polyoxyethylene ether, OP-10 and continue stirring, then add 60 parts by weight of water and stir until uniform, to obtain.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com