Salt resistance and calcium resistant deep extra-heavy oil emulsifier and viscosity dropping agent

A technology for emulsification, viscosity reduction, salt resistance and calcium resistance, which is applied in the fields of organic chemistry, chemical instruments and methods, and sulfonic acid preparation to achieve the effects of strong emulsifying ability, mild reaction conditions and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

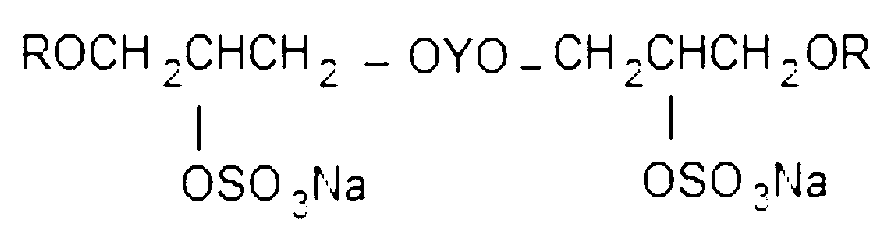

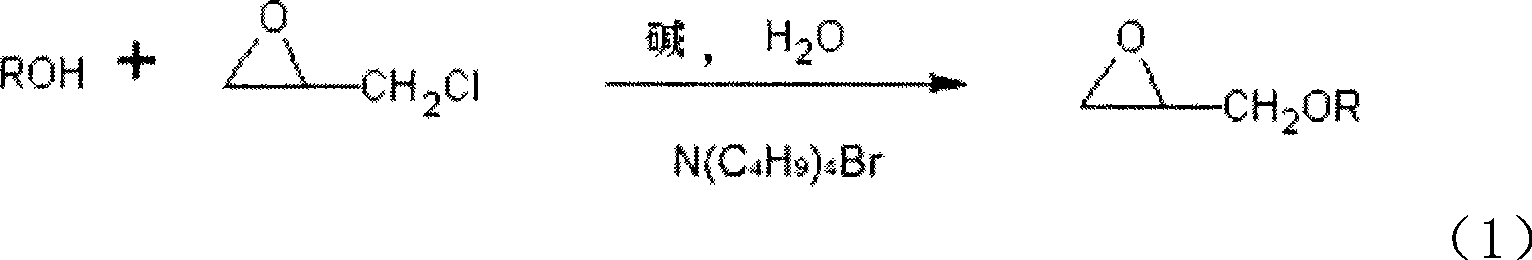

[0023] 1. Synthesis of glycerol ether

[0024] In a clean and dry three-necked flask, add 1 mol of long-chain fatty alcohol, add 1 to 1.5 mol of base, 2 to 4 mol of distilled water, and 0.015 to 0.02 mol of phase transfer catalyst tetrabutylammonium bromide. Add ring at 40°C to 55°C. Oxychloropropane is 1 to 2.5 mol, heated and stirred for reaction for 2 to 6 hours, cooled, filtered with suction, dried with anhydrous magnesium sulfate, filtered with suction, separated, and then distilled under reduced pressure to remove impurities to obtain monoglycidyl ether.

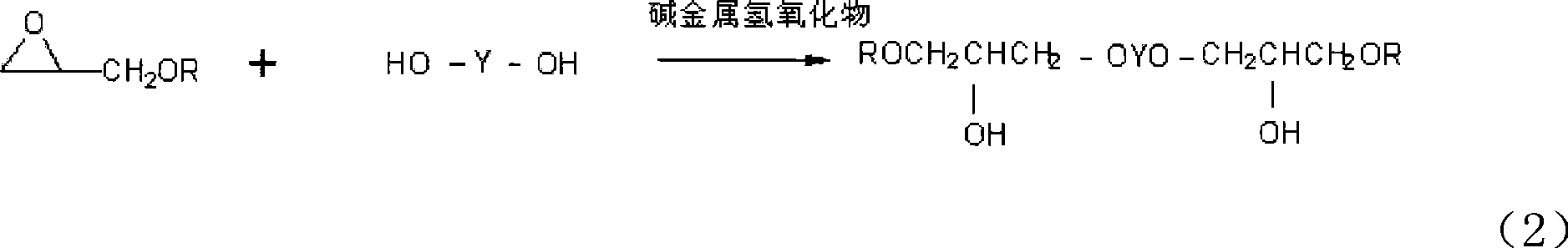

[0025] 2. Synthesis of dialkyl alkoxy glycol

[0026] Weigh 1 mol of the monoglycidyl ether prepared, and then weigh the diol at a molar ratio of 1:1 to 4:1, while adding 3% to 6% of the total mass of the alkali metal hydroxide catalyst at 90°C The reaction is stirred for 18-24 hours. After cooling, the mixture is subjected to vacuum distillation to remove impurities by using the difference in boiling points to obtain dialky...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com