Film with room temperature phosphorescence and preparation method thereof

A technology for room temperature phosphorescence and thin film preparation, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of long afterglow luminescence, high quantum yield, and difficulty in application, and achieve simple preparation methods, low synthesis temperature, and stability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: (RCH 2 CH 2 NH 3 ) 1.9 (R'CH 2 CH 2 NH 3 ) 0.1 PbBr 4 preparation of

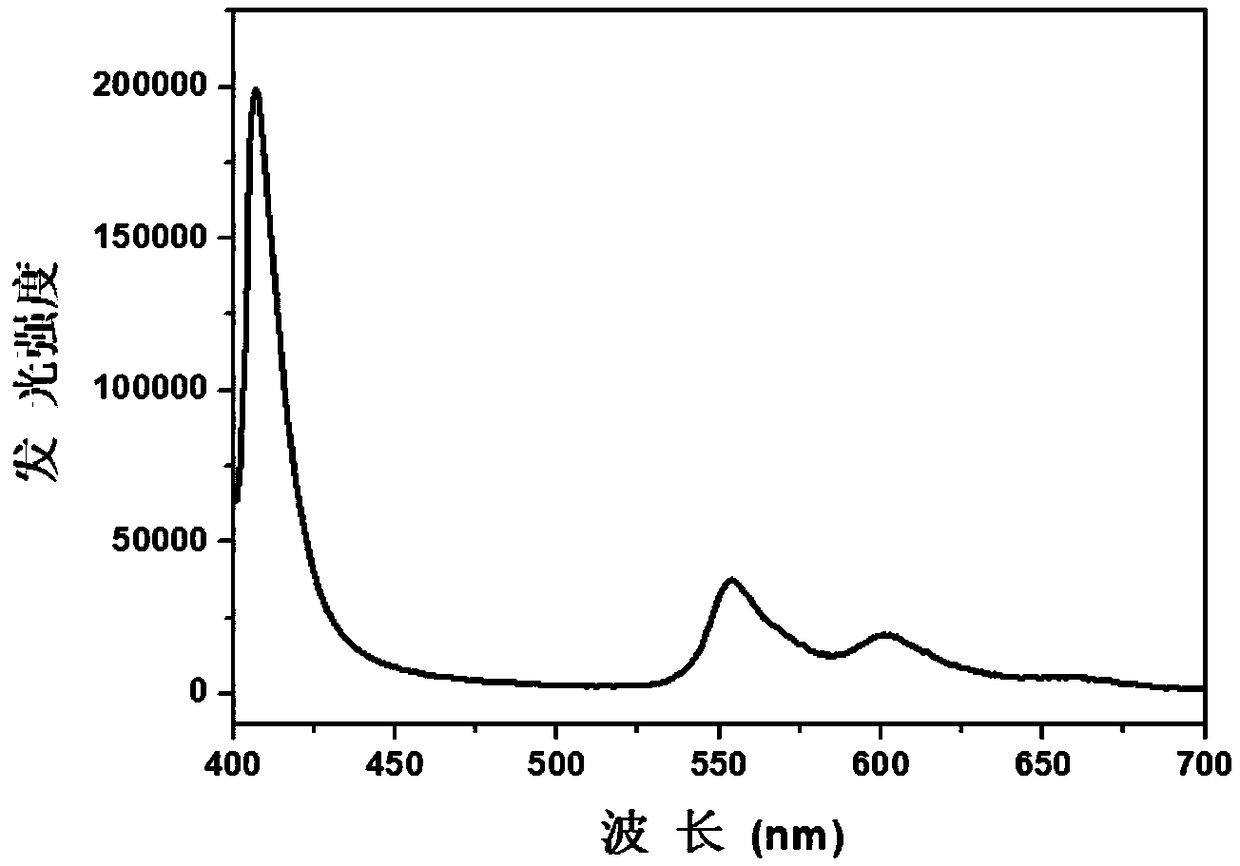

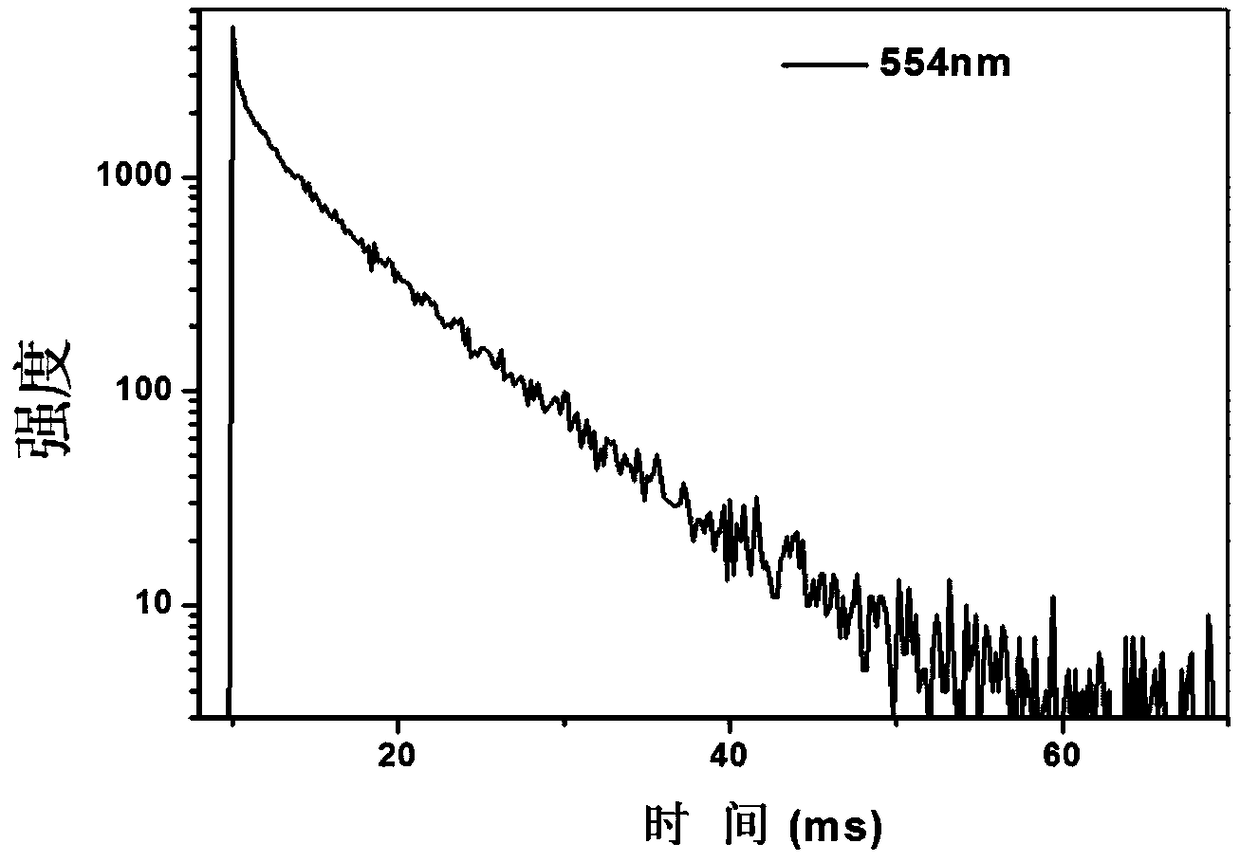

[0024] 767.6 mg (3.8 mmol) of phenethylammonium bromide salt RCH 2 CH 2 NH 3 Br and 64.2 mg (0.2 mmol) of N -(2-aminoethyl)naphthalimide hydrobromide R'CH 2 CH 2 NH 3 Br was dissolved in 10 mL of N,N-dimethylformamide, and then 734 mg (2 mmol) of lead bromide PbBr was added 2 , stirred evenly to obtain a mixed solution, and the obtained mixed solution was spin-coated on a glass sheet to form a film, the spin-coating rate was 3000R / min, the spin-coating time was 30s, and after drying in a vacuum oven at 100°C for 10 minutes, the obtained Room-temperature phosphorescent films (RCH 2 CH 2 NH 3 ) 1.9 (R'CH 2 CH 2 NH 3 ) 0.1 PbBr 4 . It appears light blue under a 365nm ultraviolet lamp, the lifetime of phosphorescence is 5.8ms, and the quantum yield is 5.5%. Its luminescence spectrum is attached figure 1 As shown, the luminescence lifetime spectrum is attached figu...

Embodiment 2

[0025] Embodiment 2: (RCH 2 CH 2 NH 3 ) 1.56 (R'CH 2 CH 2 NH 3 ) 0.44 PbBr 4 preparation of

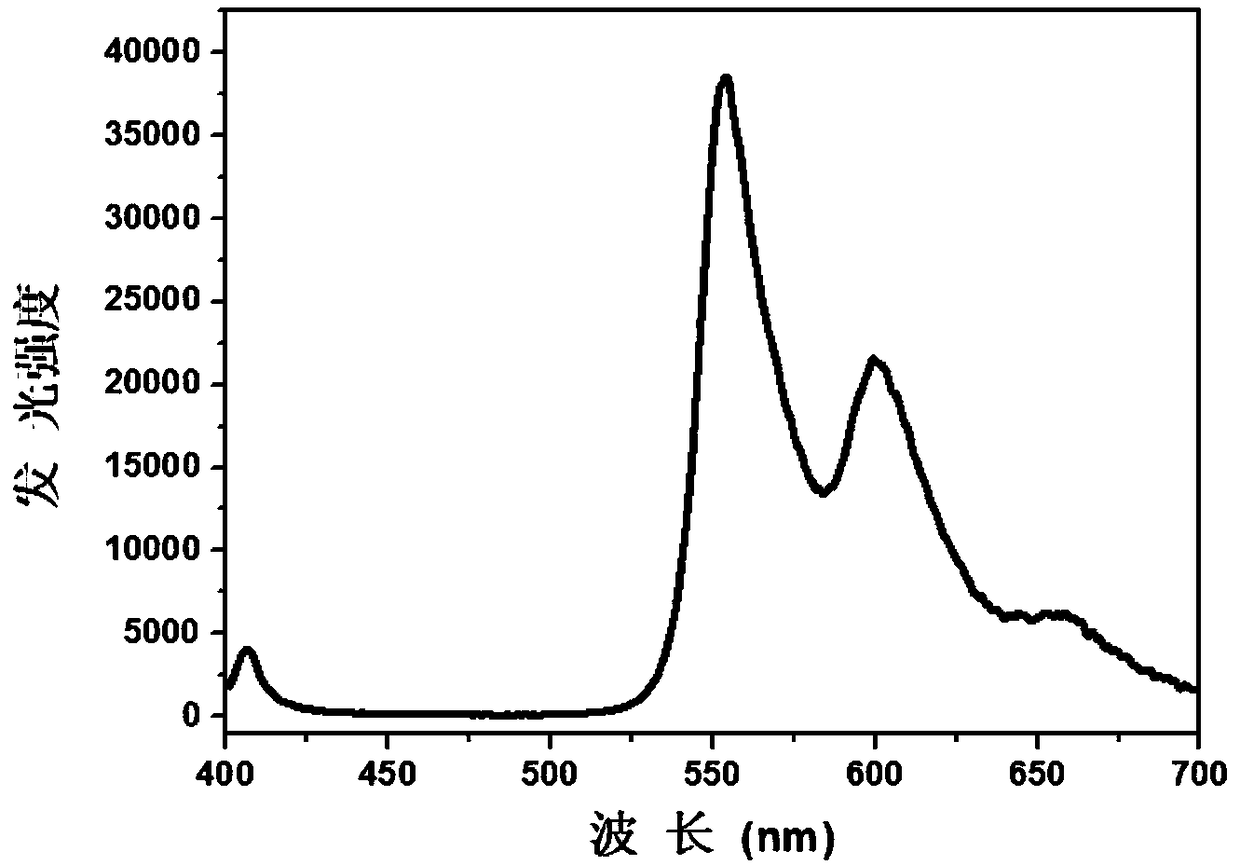

[0026] 626.2 mg (3.1 mmol) of phenethylammonium bromide salt RCH 2 CH 2 NH 3 Br and 282.48 mg (0.88 mmol) of N -(2-aminoethyl)naphthalimide hydrobromide R'CH 2 CH 2 NH 3 Br was dissolved in 10 mL of N,N-dimethylformamide, and then 734 mg (2 mmol) of lead bromide PbBr was added 2 , stirred evenly to obtain a mixed solution, and the obtained mixed solution was spin-coated on a glass sheet to form a film, the spin-coating rate was 3200R / min, the spin-coating time was 30s, and after drying in a vacuum oven at 95°C for 18 minutes, the obtained Room-temperature phosphorescent films (RCH 2 CH 2 NH 3 ) 1.56 (R'CH 2 CH 2 NH 3 ) 0.44 PbBr 4 . It appears yellow under a 365nm ultraviolet lamp, the lifetime of phosphorescence is 4.6ms, and the quantum yield is 11.4%.

[0027] The film (RCH) prepared in this embodiment 2 CH 2 NH 3 ) 1.56 (R'CH 2 CH 2 NH 3 ) 0.44 Pb...

Embodiment 3

[0028] Embodiment 3: (RCH 2 NH 3 ) 1.6 (R'CH 2 NH 3 ) 0.4 PbBr 4 preparation of

[0029] 601.6 mg (3.2 mmol) of benzyl ammonium bromide salt RCH 2 NH 3 Br and 245.6 mg (0.8 mmol) of N -(2-aminomethyl)naphthalimide hydrobromide R'CH 2 NH 3 Br was dissolved in 10 mL of N,N-dimethylformamide, and then 734 mg (2 mmol) of lead bromide PbBr was added 2 , stirred evenly to obtain a mixed solution, and the obtained mixed solution was spin-coated on a glass sheet to form a film, the spin-coating rate was 2900R / min, the spin-coating time was 28s, and after drying in a vacuum oven at 100°C for 10 minutes, the obtained Room-temperature phosphorescent films (RCH 2 NH 3 ) 1.6 (R'CH 2 NH 3 ) 0.4 PbBr 4 . It appears light yellow under a 365nm ultraviolet lamp, the lifetime of phosphorescence is 5.7ms, and the quantum yield is 9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com