Solvent type high-efficiency concentrated laundry liquid and preparation method thereof

A laundry liquid and solvent-based technology, which is applied in the field of solvent-based high-efficiency concentrated laundry liquid and its preparation, can solve the problems of low concentration technology, high energy consumption in the production process, low concentration degree and the like, and is beneficial to the product market. The effect of saving transportation cost and high-efficiency concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

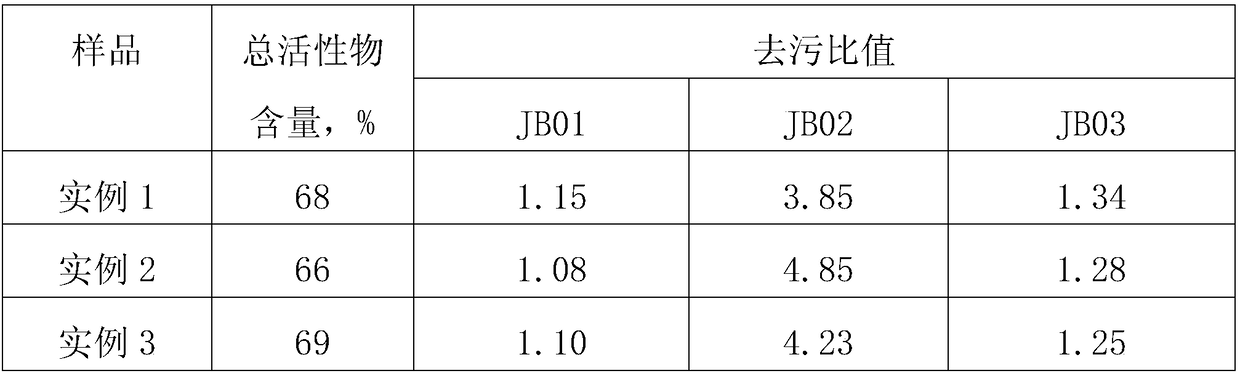

Examples

preparation example Construction

[0045] A kind of preparation method of solvent-type high-efficiency concentrated laundry detergent is:

[0046] (1) prepare materials by the mass ratio of each component above;

[0047] (2) Add organic solvent, natural fatty alcohol polyoxyethylene ether, isomeric tridecyl alcohol polyoxyethylene ether, isomeric decanol polyoxyethylene ether in sequence to the configuration tank, and start stirring;

[0048] (3) under the situation of stirring, add natural fatty alcohol polyoxyethyl ether sulfate, the time is controlled at 10 minutes;

[0049] (4) And under the situation of continuous stirring, add organic base, bactericide and enzyme preparation successively, time is controlled at 5 minutes.

[0050] (5) Semi-finished products are subjected to aging treatment;

[0051] (6) Sampling inspection, finished product packaging.

Embodiment 1

[0053] Coco fatty alcohol polyoxyethylene ether 30 kg, isomeric tridecyl alcohol polyoxyethylene ether 10 kg, isomeric decanol polyoxyethylene ether 10 kg, palm oil polyoxyethylene sodium sulfate 25.5 kg; monoethanolamine 0.5 kg , 2,4,4'-trichloro-2'-hydroxydiphenyl ether 0.6 kg, savinase 16XL 0.5 kg and ethylene glycol 22.9 kg.

[0054] The raw materials are prepared according to the above-mentioned preparation method into finished products of solvent-type high-efficiency concentrated laundry detergent.

Embodiment 2

[0056]Coco fatty alcohol polyoxyethylene ether 20 kg, isomeric tridecyl alcohol polyoxyethylene ether 20 kg, isomeric decanol polyoxyethylene ether 15 kg; coco fatty alcohol polyoxyethylene ether sodium sulfate 30 kg; triethanolamine 0.2 kg, o-phenylphenol 1 kg, Progress Uno100L 1 kg, and ethanol 22.8 kg.

[0057] The raw materials are prepared according to the above-mentioned preparation method into finished products of solvent-type high-efficiency concentrated laundry detergent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com