Method for increasing biological value of kasugamycin

A technology of kasugamycin and biological potency, which is applied in the field of biological fermentation, can solve the problems of lack of experimental conditions and related equipment, stable heredity of mutation breeding, etc., so as to increase the output of a single tank, reduce production capacity and energy consumption, and improve the production capacity of kasugamycin. effect on biopotency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

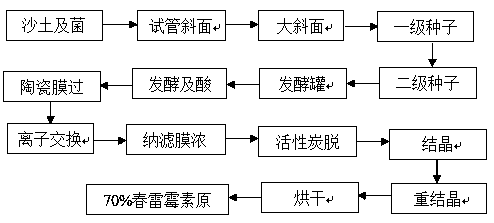

Method used

Image

Examples

Embodiment 1

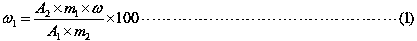

[0043] The mass percentage of each substance in the kasugamycin fermentation medium: soybean meal powder 8.0%, NaCl 0.5%, corn steep liquor dry powder 0.8%, maltose 2.5%, fish oil 3.5%, KH 2 PO 4 0.03%, inositol 0.03%, and the mass percentage of trace elements are 0.002%, 0.004%, 0.006%, 0.008%, 0.010%, 0.012%, and double distilled water is added to 100%, and the medium is configured according to the above ratio. After sterilization, inoculate Streptomyces aureus into 300mL shake flasks with an inoculation volume of 150mL for each shake flask. Set up three parallel sample groups for a certain mass percentage of trace element groups, and set up a non-added trace element group (control group) ), adding trace elements as the experimental group. All shake flask samples were cultured continuously for 178 hours in a biological shaker for the determination of kasugamycin. The culture temperature was 25°C and the rotation speed was 120r / min. The specific experimental results are sh...

Embodiment 2

[0048] The mass percentage of each substance in the kasugamycin fermentation medium: soybean meal powder 8.0%, NaCl 0.5%, corn steep liquor dry powder 0.8%, maltose 2.5%, fish oil 3.5%, KH 2 PO 4 0.03%, inositol 0.03%, the mass percentage of growth factor is 0.01%, 0.013%, 0.015%, 0.017%, 0.019%, 0.021%, double distilled water supplemented to 100%, and the medium is configured according to the above ratio. After sterilization, Streptomyces aureus was inoculated into 300mL shake flasks with an inoculation volume of 150mL for each shake flask. Three parallel samples were set for each growth factor group, and no growth factor added group (control group), growth The factor is the experimental group. All the shake flask samples were cultured continuously for 178 hours in a biological shaker for the determination of kasugamycin. The culture temperature was 25°C and the rotation speed was 120r / min. The specific experimental results are shown in Table 2.1 below.

[0049] Table 2.1...

Embodiment 3

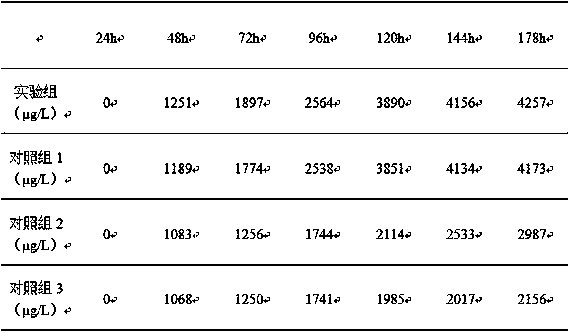

[0053] The mass percentage of each substance in the kasugamycin fermentation medium: soybean meal powder 8.0%, NaCl 0.5%, corn steep liquor dry powder 0.8%, maltose 2.5%, fish oil 3.5%, KH 2 PO 4 0.03%, inositol 0.03%, trace elements 0.006%, growth factors 0.017%, double distilled water to 100%. After the culture medium is sterilized, inoculate Streptomyces aureus into 300m L shake flasks with a volume of 150m L for each shake flask. Experimental group=common medium+growth factor+trace elements, control group 1=common medium+ Growth factors, control group 2 = ordinary medium + trace elements, control group 3 = ordinary medium group. Three parallel samples were set up in each group, and all shake flask samples were cultured continuously for 178 hours in a biological shaker for the determination of kasugamycin. The culture temperature was 25°C and the rotation speed was 120r / min. The specific results are shown in Table 3.1 below.

[0054] 3.1 Changes of kasugamycin in each g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com