Method for conducting amorphous TiO2 pulsed chemical vapor phase deposition on TiO2 particle surfaces

A technology of chemical vapor deposition and particle surface, which is applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of titanium dioxide pigment optical performance and cost increase, and achieve high decolorization power and operation Convenience and enhanced weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] a. Dry the anatase titanium dioxide at 120 °C for 90 minutes to remove the adsorbed water on the surface of the titanium dioxide.

[0020] b. Weigh 1.5g of dried titanium dioxide and disperse it in a petri dish, and place it in a vacuum desiccator.

[0021] c. Take a certain amount of TiCl with a sample bottle 4 , and placed in a vacuum desiccator, and evacuated to a vacuum degree of 0.095Mpa.

[0022] d. After standing for 60 min, part of the unreacted TiCl 4 Pump into the NaOH solution, then open the cover, let the water vapor in the air enter the reactor, and let it stand for 30 minutes, take out the titanium dioxide, and bake it in an oven at 105 °C for 120 minutes.

[0023] e. Repeat the above operations to increase amorphous TiO 2 Thickness of the film.

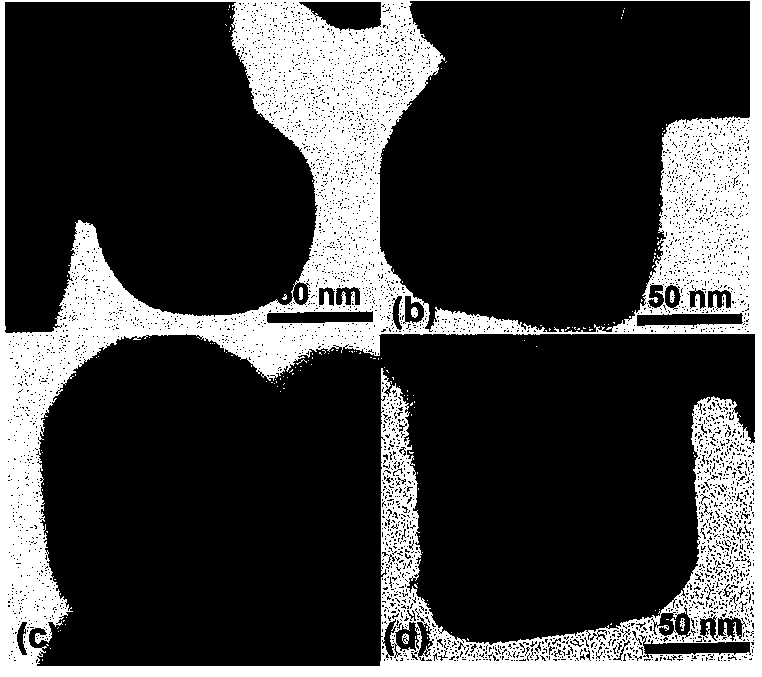

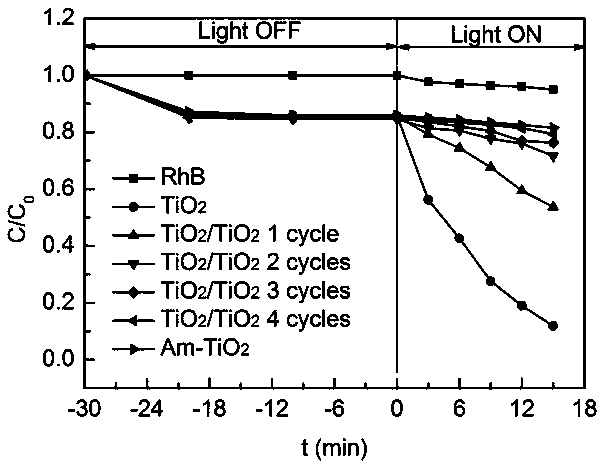

[0024] Take a small amount of the above-mentioned method obtained through 1 time ( figure 1 b), 2 times ( figure 1 c) and 3 times ( figure 1 d) coated titanium dioxide, and with uncoated titanium dioxide (...

Embodiment 2

[0027] a. Dry the titanium dioxide in a desiccator to remove the outer layer of adsorbed water on the surface of the titanium dioxide.

[0028] b. Take 1 Kg of dried titanium dioxide and place it in a titanium reactor with a volume of 15L (d=0.3 m, H=0.2 m).

[0029] c. Vacuum until the vacuum degree of the reactor is 0.095MPa, and then open the 4 connected to the valve so that the TiCl 4 Volatilize into the reactor, and place the whole reactor on the shaker for 100 min to shake TiCl 4 Full contact with titanium dioxide.

[0030] d. After the reaction, part of the unreacted TiCl 4 After the NaOH solution is pumped into the reactor, humid air containing relatively high water vapor is passed into the reactor to make the TiCl connected to the hydroxyl group 4 further hydrolysis.

[0031] e. Dry the coated titanium dioxide at 105°C, and repeat the above process to obtain amorphous TiO with different thicknesses 2 film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com