Preparation method of a colorimetric stress sensor based on ag nanoparticle assembly

A stress sensor and nanoparticle technology, applied in the field of colorimetric stress sensor preparation, can solve the problems of high price, low Au storage capacity, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A method for preparing a colorimetric stress sensor based on an Ag nanoparticle assembly, comprising the following steps: dispersing an Ag nanoparticle assembly with an SPR absorption range of 400-490nm in deionized water, and preparing a concentration of 5 mg / mL for later use.

[0041] Heat and dissolve polyvinyl alcohol (PVA) (Mw=130000) at 90° C. to prepare a PVA aqueous solution with a concentration of 10 wt. % for later use.

[0042] Take 300uL of the above-mentioned Ag nanoparticle assembly solution (5mg / mL), 10g of polyvinyl alcohol (PVA) aqueous solution (10wt.%) and 0.1g of polyethylene glycol (PEG) (Mn=800) and mix them with mechanical stirring. .

[0043] Pour the uniformly mixed PVA / Ag nanoparticle assembly into a mold with a length*width*height of 6cm*4cm*2cm, and heat it at 40°C to form a film to obtain a colorimetric stress sensor.

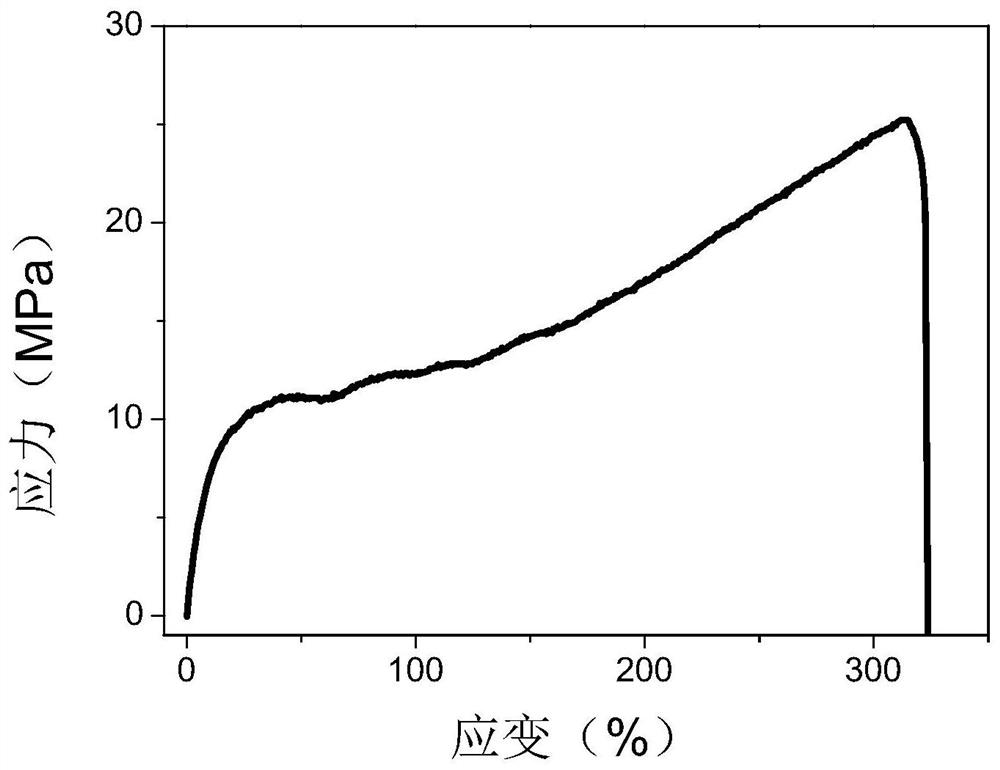

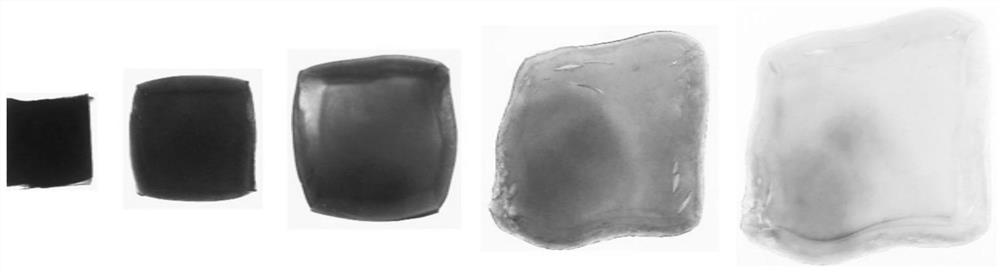

[0044] The composite film prepared in this embodiment can change from blue-purple to red to orange and finally to yellow m...

Embodiment 2

[0046] Embodiment 2, change the SPR absorption range of Ag nanoparticle assembly

[0047] As described in Example 1, a method for preparing a colorimetric stress sensor based on an Ag nanoparticle assembly includes the following steps:

[0048] Disperse the Ag nanoparticle assembly with the SPR absorption range of 400-550nm in deionized water, and prepare the concentration at 5mg / mL for later use.

[0049] Heat and dissolve PVA (Mw=130000) at 90° C., and prepare a PVA aqueous solution with a concentration of 10 wt. % for later use.

[0050] Take 300uL of the above-mentioned Ag nanoparticle assembly (5mg / mL), 10g of polyvinyl alcohol (PVA) aqueous solution (10wt.%) and 0.1g of polyethylene glycol (PEG) (Mn=800) and mix them with mechanical stirring. Pour the uniformly mixed PVA / Ag nanoparticle assembly into a mold with a length*width*height of 6cm*4cm*2cm, and heat it at 40°C to form a film to obtain a colorimetric stress sensor.

[0051]The colorimetric stress sensor is dark...

Embodiment 3

[0052] Embodiment 3, PVA is changed into polyvinylpyrrolidone PVP

[0053] As described in Example 1, a method for preparing a colorimetric stress sensor based on an Ag nanoparticle assembly includes the following steps:

[0054] Disperse the Ag nanoparticle assembly with the SPR absorption range of 400-490nm in deionized water, and prepare the concentration of 5mg / mL for later use.

[0055] Heat and dissolve polyvinylpyrrolidone (PVP) (Mw=30000) at 90° C. to prepare an aqueous solution with a concentration of 12 wt. % for later use.

[0056] Take 300uL of the above-mentioned Ag nanoparticle assembly (5mg / mL), 10g of PVP aqueous solution (12wt.%) and 0.1g of polyethylene glycol (PEG) (Mn=800) and mix them with mechanical stirring.

[0057] Pour the evenly mixed PVA / Ag nanoparticle assembly into a mold with length*width*height 6cm*4cm*2cm, and heat it at 60°C to form a film to obtain a colorimetric stress sensor.

[0058] The colorimetric stress sensor is blue-purple macrosco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com