Impact-resistant self-cleaning material transfer point rubber chute lining plate

A self-cleaning, impact-resistant technology, applied in the field of rubber chute liners, can solve the problems of low impact resistance, easy material accumulation, high specific weight, etc., achieve excellent impact resistance and tear strength, buffer material impact, and increase buffering effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

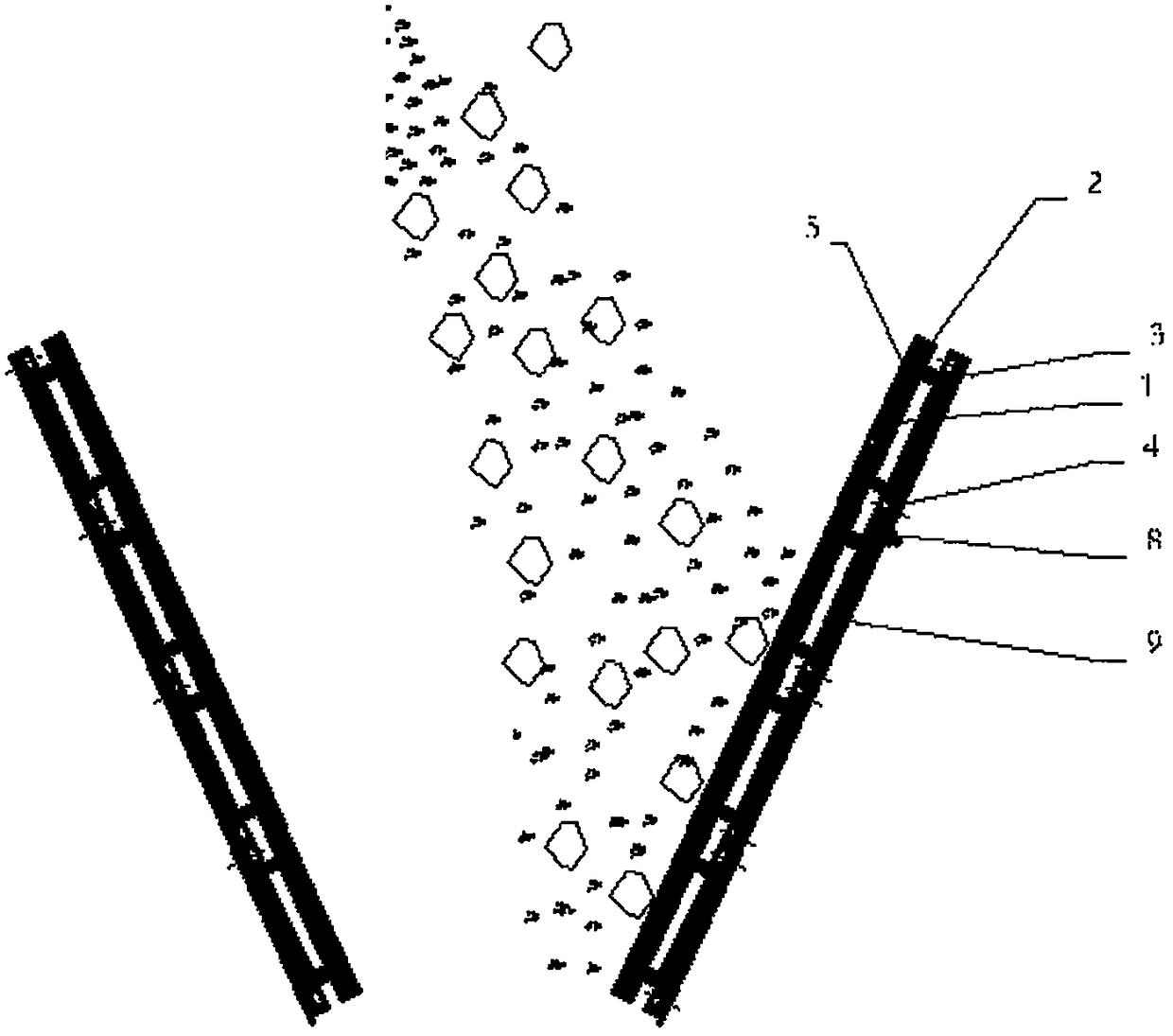

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

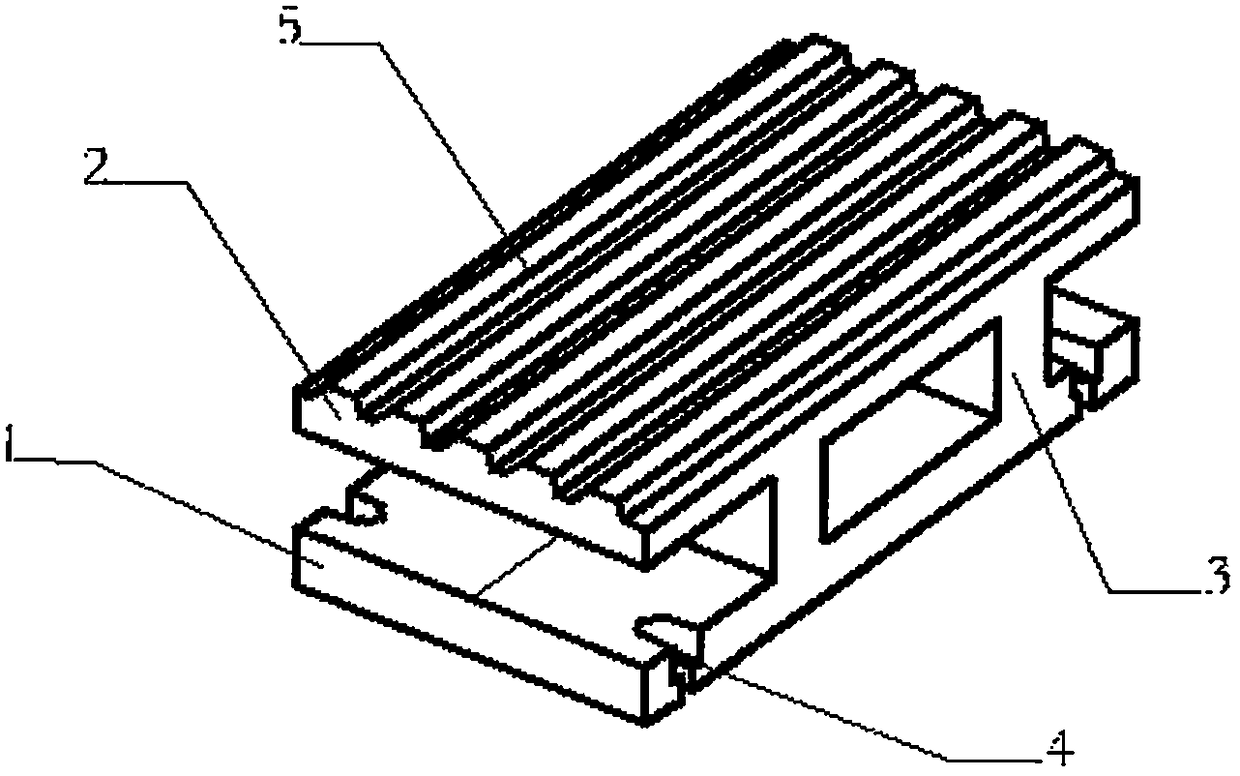

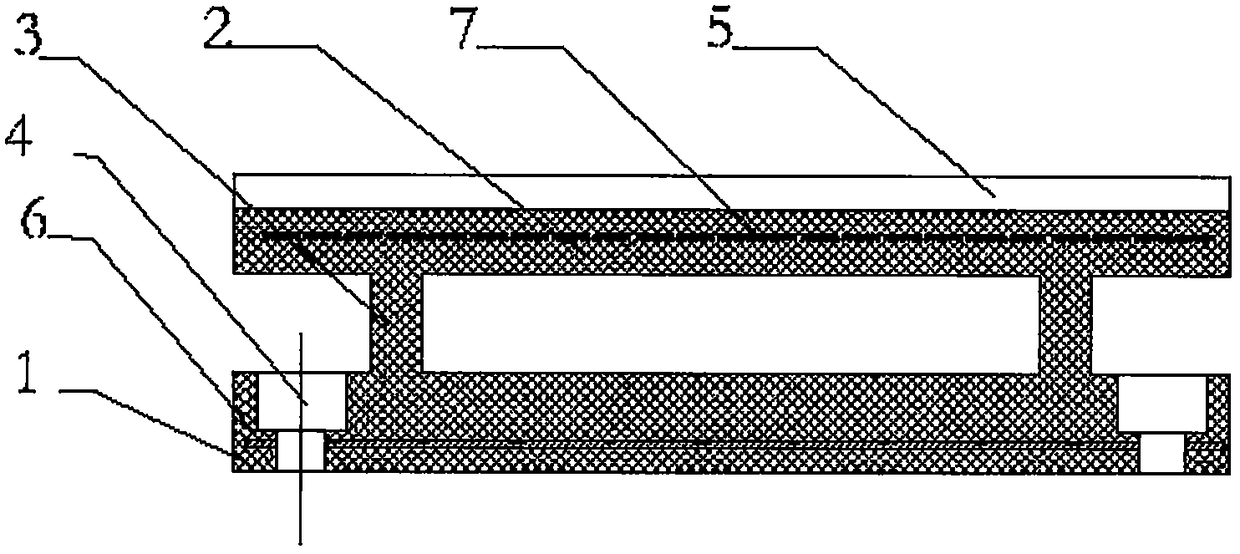

[0014] like figure 1 As shown, the rubber liner is a whole, made of high-performance rubber and aramid mesh skeleton 2 compound vulcanized. The formula of the high-performance rubber is: 60 parts of natural rubber, 30 parts of styrene-butadiene rubber, 10 parts of reclaimed rubber, 5 parts of zinc oxide, 3 parts of stearic acid, 1.5 parts of paraffin, 1 part of coumarone, anti-aging agent A: 1 part, antioxidant D: 2.2 parts, carbon black 234: 38 parts, white carbon black N220: 12 parts, pine tar oil 5 parts, accelerator DZ: 1 part, sulfur 2.8 parts, silane coupling agent: 0.5 parts , Microcrystalline cellulose: 4 parts, total mass parts: 177 parts.

[0015] The microcrystalline cellulose is added in stages during the mixing stage, and the rubber liner is produced by a conventional vulcanization process at a temperature of 155° C. for 55 minutes.

[0016] like fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com