Preparation method of full-biodegrade edible preservative film

A fresh-keeping film and all-biological technology, applied in the field of preparation of fully biodegradable edible fresh-keeping film, can solve the problems of high price, limited source of casein, poor film-forming ductility, etc., and achieve low price, increased tensile strength, increased good plastic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

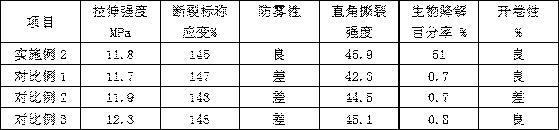

Examples

Embodiment 1

[0017] A fully biodegradable edible preservative film, made of the following raw materials in parts by weight: 60 parts of modified starch, 40 parts of edible gelatin, 30 parts of soybean meal, 15 parts of carboxymethyl cellulose, 1 part of chitosan, plasticized 5 parts of water, 1 part of citric acid, 1 part of antibacterial oil, 5 parts of ginger juice, 5 parts of glutinous rice juice, 5 parts of carrot powder

[0018] A method for preparing a fully biodegradable edible plastic wrap, comprising the following steps: (1) respectively mixing soybean meal and clear water according to the mass ratio of material to liquid at 1:8, adjusting the pH value to 7.5 with 0.5mol / L NaOH, and maintaining the temperature at 45°C After extraction for 10 minutes, filter with double-layer gauze and keep the filtrate, and add 2 times deionized water to the filter residue and stir evenly, then pass it through a water mill to grind evenly, add 3 times deionized water after grinding, and use 0.5mol ...

Embodiment 2

[0023] A fully biodegradable edible fresh-keeping film is made of the following raw materials in parts by weight: 60 parts of modified starch, 60 parts of edible gelatin, 60 parts of soybean meal, 15 parts of carboxymethyl cellulose, 3 parts of chitosan, 5 parts plasticizer, 15 parts water, 5 parts citric acid, 5 parts antibacterial oil, 5 parts ginger juice, 5 parts glutinous rice juice, 5 parts carrot powder.

[0024]A method for preparing a fully biodegradable edible plastic wrap, comprising the following steps: (1) respectively mixing soybean meal and clear water according to the mass ratio of material to liquid at 1:8, adjusting the pH value to 7.5 with 0.5mol / L NaOH, and maintaining the temperature at 45°C After extraction for 10 minutes, filter with double-layer gauze and keep the filtrate, and add 2 times deionized water to the filter residue and stir evenly, then pass it through a water mill to grind evenly, add 3 times deionized water after grinding, and use 0.5mol / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com