Anticoagulant fiber membrane and preparation method and application thereof

A fiber membrane and anti-coagulation technology, which is applied in the fields of fiber chemical characteristics, rayon manufacturing, textiles and papermaking, etc., can solve the problems of reducing the stability of membrane materials and the stability of modifiers, and achieve anti-coagulation effects Good, good hydrophilic performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

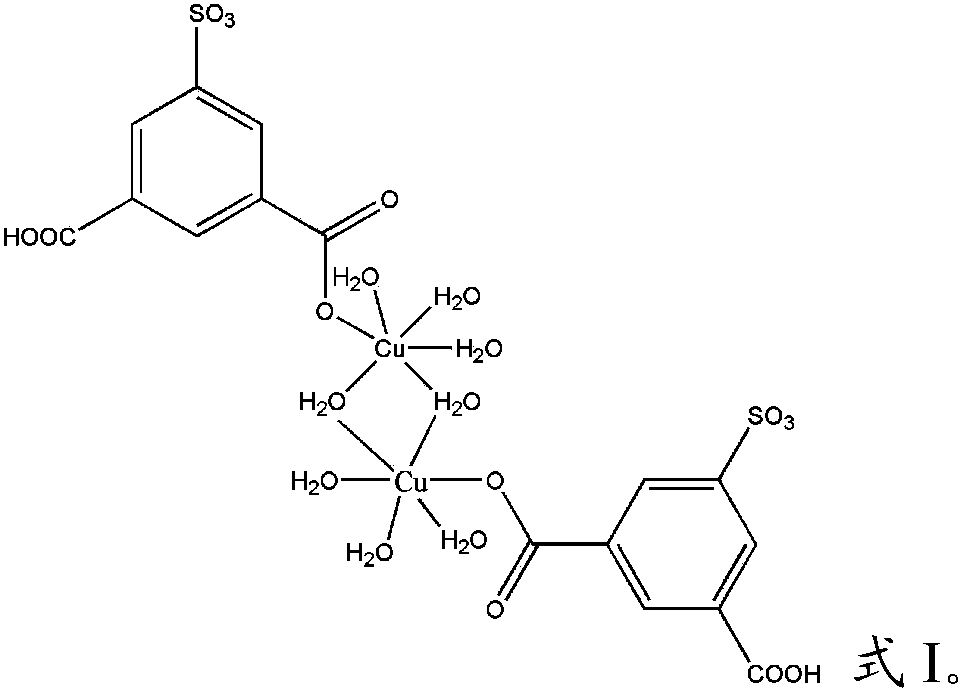

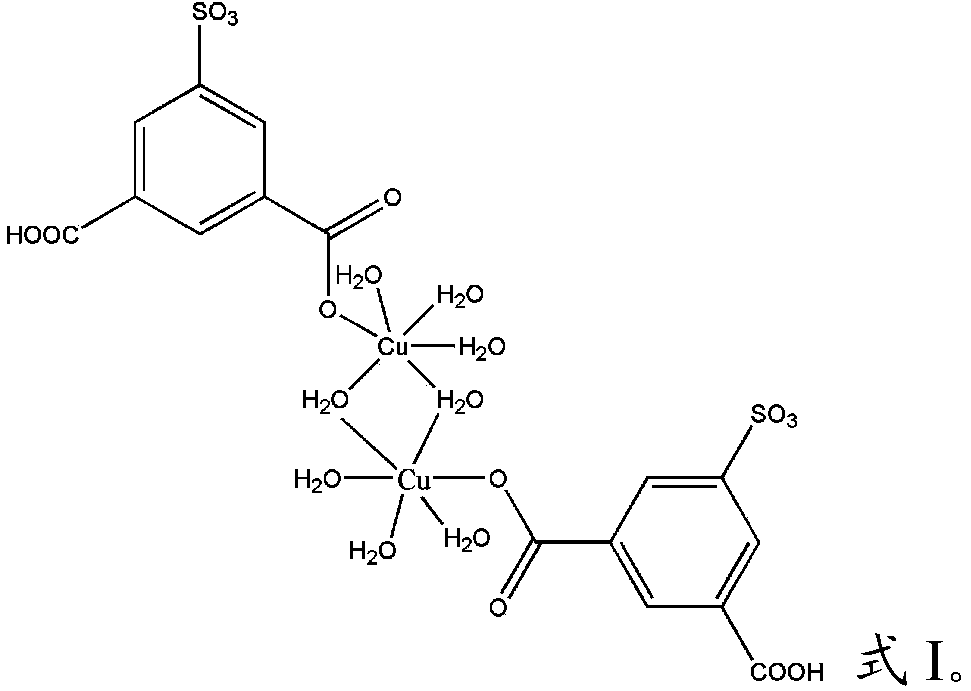

[0030] In the present invention, there is no special requirement on the source of the metal organic framework material with carboxyl groups, and the products well known to those skilled in the art are used or prepared by themselves. When the metal organic framework material with carboxyl group is obtained by self-preparation, the preparation method of the metal organic framework material with carboxyl group preferably includes the following steps:

[0031] (a) mixing monosodium 5-thioisophthalate, copper nitrate, N,N-dimethylformamide and water to obtain a mixed material liquid; then standing the mixed material liquid to precipitate precipitation;

[0032] (b) mixing the precipitate obtained in the step (a) with an aqueous ethanol solution, standing still, and depositing crystals to obtain a metal organic framework material with a carboxyl group.

[0033] In the present invention, it is preferred to mix monosodium 5-thioisophthalate, copper nitrate, N,N-dimethylformamide and w...

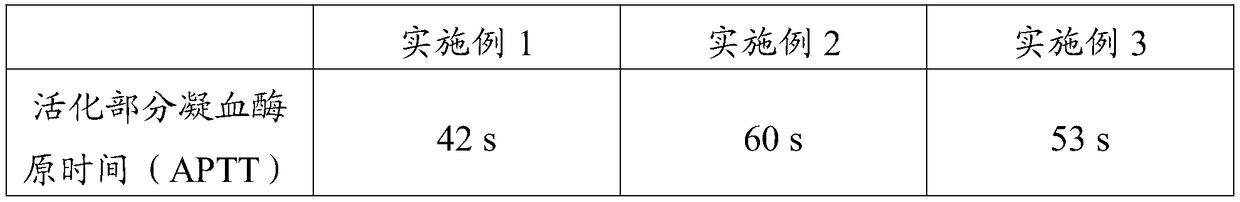

Embodiment 1

[0078] A metal-organic framework material Cu 2 (μ 2 -OH 2 ) 2 (HSIP) 2 (H 2 O) 6 Hybrid polyvinylidene fluoride membrane anticoagulant fiber membrane preparation method, the method steps are as follows:

[0079] (1) Dissolve monosodium 5-thioisophthalate (0.932 mmol) in 3 mL of deionized water and N,N-dimethylformamide (volume ratio 1:1) and stir at 70°C for 10 minutes. Add Cu(NO 3 ) 2 ·3H 2 O (0.340 mmol) aqueous solution 0.5 mL, stirred for 30 minutes. Filtration, the mother liquor was left standing for 4 weeks, precipitation occurred, and the precipitation was dissolved in a mixed solution of 2mL of deionized water and ethanol (volume ratio 1:1), and a blue-green solution was obtained at room temperature. After standing for 2 weeks, a blue-green solution was obtained. color crystals, washed with deionized water, dried and ground to obtain metal organic framework materials with carboxyl groups;

[0080] (2) Add 0.1 parts by mass of metal-organic framework material...

Embodiment 2

[0084] A metal-organic framework material Cu 2 (μ 2 -OH 2 ) 2 (HSIP) 2 (H 2 O) 6 Hybrid polyvinylidene fluoride membrane anticoagulant fiber membrane preparation method, the method steps are as follows:

[0085] (1) Dissolve monosodium 5-thioisophthalate (0.932 mmol) in 3 mL of deionized water and N,N-dimethylformamide (volume ratio 1:1) and stir at 70°C for 10 minutes. Add Cu(NO 3 ) 2 ·3H 2O (0.340 mmol) aqueous solution 0.5 mL, stirred for 30 minutes. Filtration, the mother liquor was left standing for 4 weeks, precipitation occurred, and the precipitation was dissolved in a mixed solution of 2mL of deionized water and ethanol (volume ratio 1:1), and a blue-green solution was obtained at room temperature. After standing for 2 weeks, a blue-green solution was obtained. color crystals, washed with deionized water, dried and ground to obtain metal organic framework materials with carboxyl groups;

[0086] (2) Add 4 parts by mass of metal-organic framework materials w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com