Hard roof orientation acidification fracturing roof control pressure relief method

A technology of acid fracturing and hard roof, which is applied in earth square drilling, ground mining, underground mining, etc. It can solve the problems of high gas mine safety hazards, waste of coal resources, etc., to increase the stability of coal pillars, reduce the number of renovations, Obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

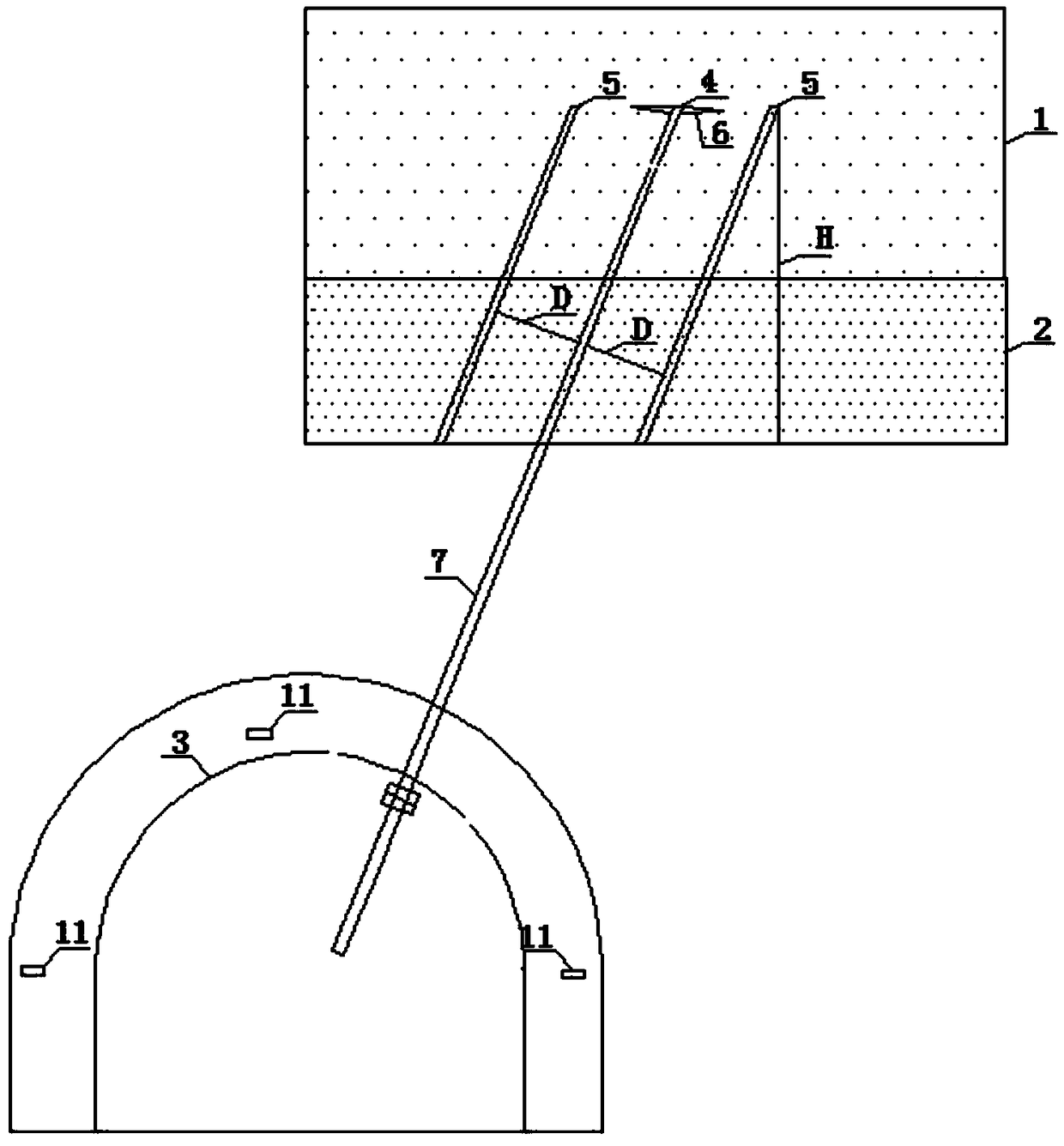

[0057] Such as Figure 1-Figure 3 Shown, the present embodiment coal seam 10 thickness M is 18m, specifically comprises the following steps:

[0058] Step 1: Determine the fracturing target layer 1:

[0059] On the premise of grasping the hard roof layer overlying the coal seam and the properties of interlayer rock strata, according to the key layer theory, a reasonable fracturing target layer 1 is obtained;

[0060] Step 2: Arranging the acidizing fracturing roadway 3:

[0061] The coal seam 10 is an extra-thick coal seam, so before the working face is recovered, the acidizing fracturing roadway 3 is constructed along the roof of the coal seam 10 in the coal pillar 8, and the horizontal offset S between the acidizing fracturing roadway and the recovery roadway is 9m;

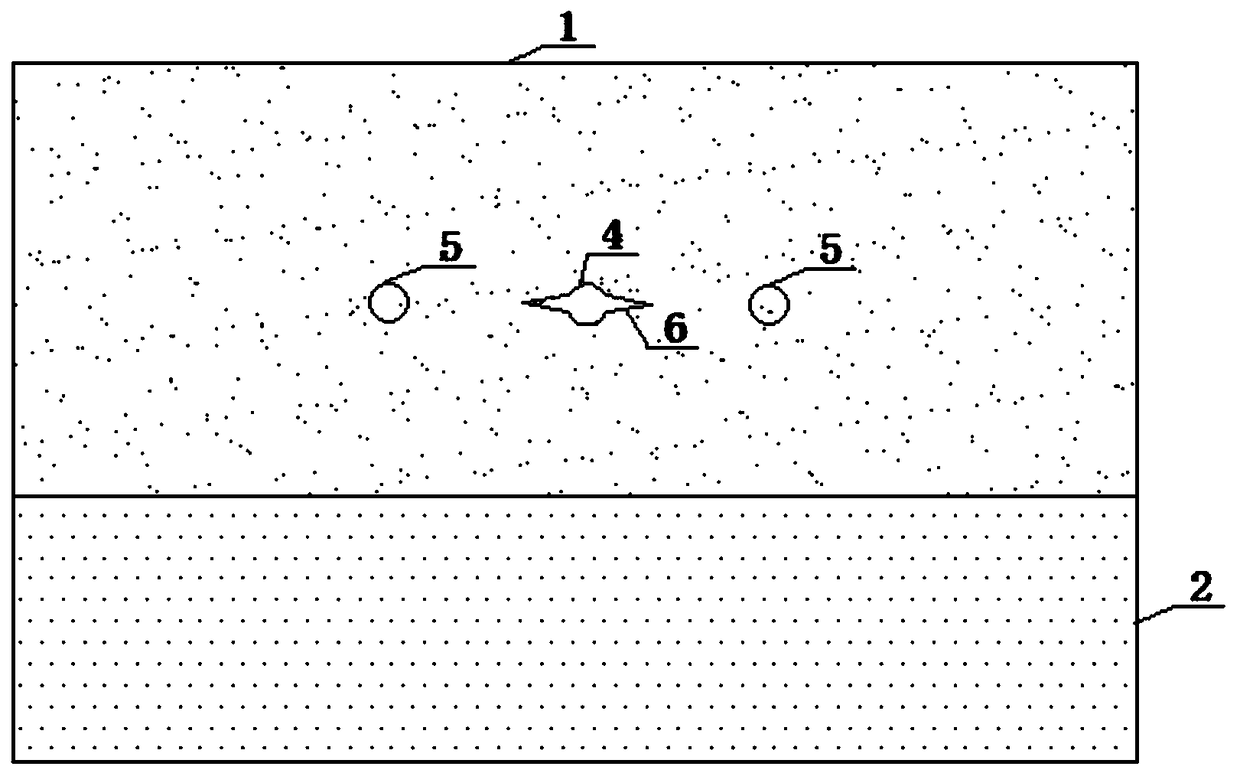

[0062] Step 3: Arranging fracturing holes 4, guide holes 5 and wedge grooves 6:

[0063] In the fracturing target layer 1 above the acidizing fracturing roadway 3, fracturing holes 4 and guide holes 5 are a...

Embodiment 2

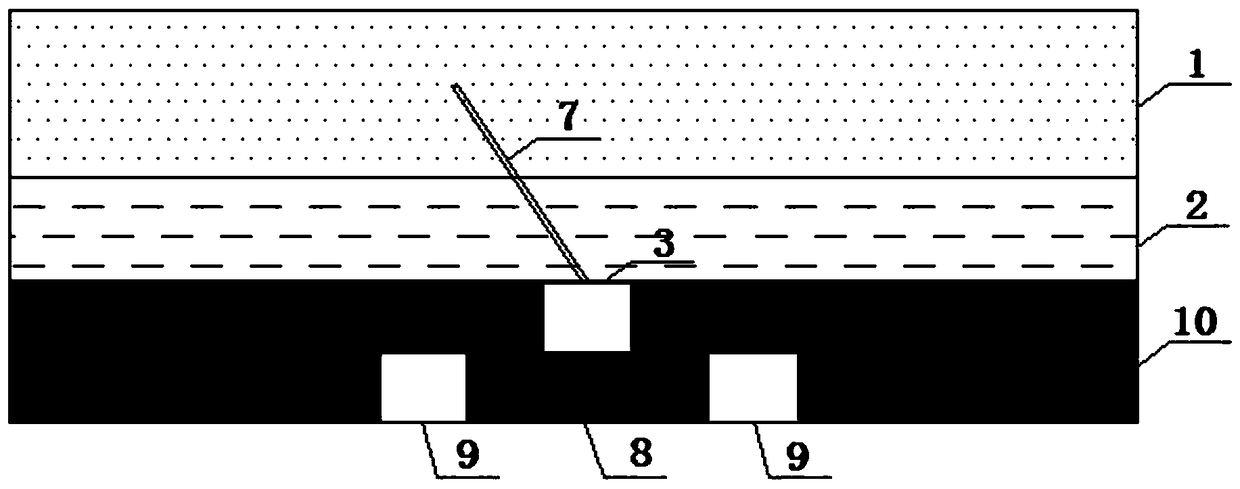

[0067] Such as Figure 4-Figure 5 Shown, the present embodiment coal seam thickness M is 6.5m, specifically comprises the following steps:

[0068] Step 1: Determine the fracturing target layer 1:

[0069] On the premise of grasping the hard roof layer overlying the coal seam and the properties of interlayer rock strata, according to the key layer theory, a reasonable fracturing target layer 1 is obtained;

[0070] Step 2: Arranging the acidizing fracturing roadway 3:

[0071] The coal seam 10 is a thick coal seam, and the mining roadway 9 is used as the acidizing and fracturing roadway 3;

[0072] Step 3: Arranging fracturing holes 4, guide holes 5 and wedge grooves 6:

[0073] In the coal seam 10 above the entire acidizing fracturing roadway 3 and the roof rock layer 8, there are longitudinally arranged fracturing holes 4 and guide holes 5 at a certain angle with the coal seam inclination, and the guide holes 5 are arranged between adjacent fracturing holes 4. Middle pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com