Catalytic low-nitrogen combustion hood device and process

A low-nitrogen combustion and catalytic cover technology, which is applied in the direction of combustion, combustion type and combustion method using catalytic materials, can solve the problems affecting fuel combustion conditions and burnout effects, so as to promote complete combustion, reduce NOx content, Energy Saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

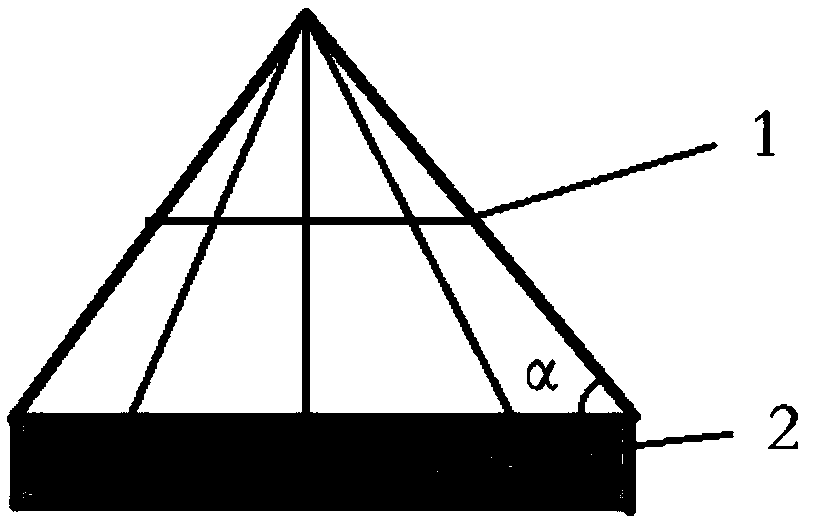

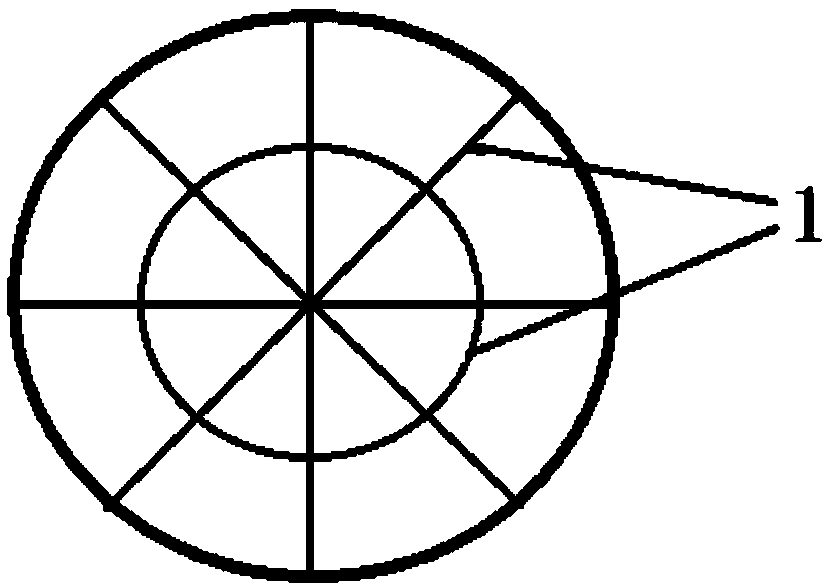

[0032] 1. A catalytic low-nitrogen combustion hood device, such as Figure 1-2 As shown, it includes a combustion catalytic cover and a connecting piece 2. The combustion catalytic cover is installed on the nozzle of the burner through the connecting piece 2, and is used in conjunction with the burner to form a low-nitrogen combustion system.

[0033] The combustion catalytic cover is composed of a catalyst carrier 1 and a catalyst, wherein the catalyst carrier 1 is used as a main frame, the catalyst is distributed on the main frame, and the catalyst carrier is made of ceramic material.

[0034]The shape of the combustion catalytic cover is conical, so that it can cooperate with the combustion flame, and provide a good working temperature condition for the catalyst with the help of the temperature generated by the combustion flame, so as to achieve the purpose of energy saving.

[0035] The connecting piece 2 is threaded so as to connect the combustion catalytic cover 1 to the...

Embodiment 2

[0040] 1. A catalytic low-nitrogen combustion hood device, such as Figure 1-2 As shown, it includes a combustion catalytic cover and a connecting piece 2. The combustion catalytic cover is installed on the nozzle of the burner through the connecting piece 2, and is used in conjunction with the burner to form a low-nitrogen combustion system.

[0041] The combustion catalytic cover is composed of a catalyst carrier 1 and a catalyst, wherein the catalyst carrier 1 is used as a main body skeleton, and the catalyst carrier is made of catalyst capable of catalyzing CO and NO x The high-temperature-resistant material of the reaction is made of iron-copper-manganese stainless steel alloy, so that the main frame itself can also serve as a catalyst.

[0042] The shape of the combustion catalytic cover is conical, so that it can cooperate with the combustion flame, and provide a good working temperature condition for the catalyst with the help of the temperature generated by the combus...

Embodiment 3

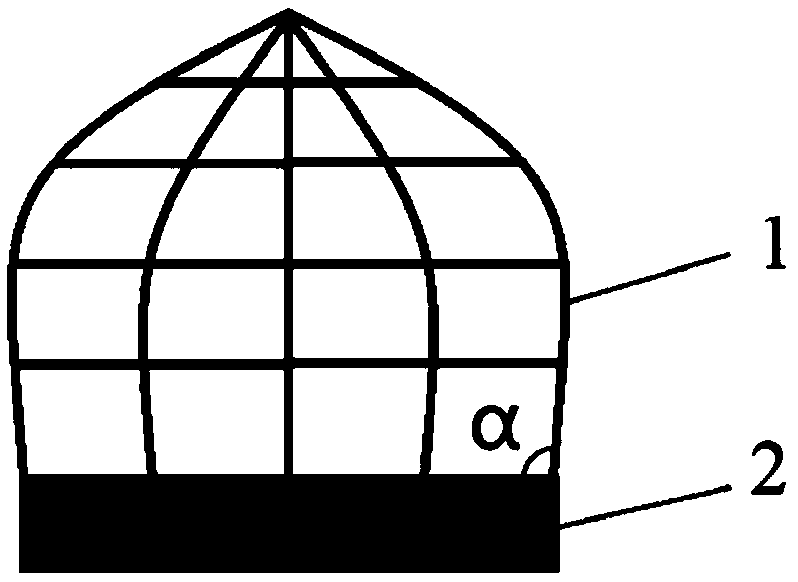

[0048] 1. A catalytic low-nitrogen combustion hood device, such as Figure 3-4 As shown, it includes a combustion catalytic cover and a connecting piece 2. The combustion catalytic cover is installed on the nozzle of the burner through the connecting piece 2, and is used in conjunction with the burner to form a low-nitrogen combustion system.

[0049] The combustion catalytic cover is composed of a catalyst carrier 1 and a catalyst, wherein the catalyst carrier 1 is used as a main body skeleton, and the catalyst carrier is made of catalyst capable of catalyzing CO and NO x The reaction high-temperature-resistant Fe / Cu / Zn / Ce / Ti high-entropy alloy is molded, so that the main frame itself can also serve as a catalyst.

[0050] The shape of the combustion catalytic cover is flame-shaped, so that it can cooperate with the combustion flame, and provide a good working temperature condition for the catalyst with the help of the temperature generated by the combustion flame, so as to a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com