Pressure and temperature sensor based on wafer bonding and manufacturing method thereof

A technology of temperature sensor and manufacturing method, applied in the direction of instruments, measuring instrument components, measuring devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

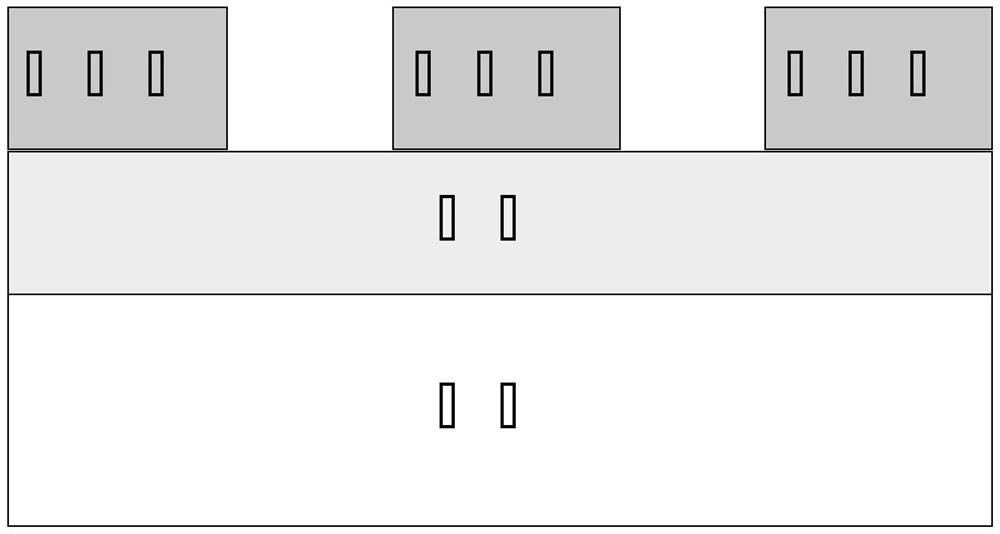

[0039] The manufacturing method of the pressure and temperature sensor based on wafer bonding of the present invention comprises the following steps:

[0040] 1) making a metal layer on a silicon wafer; the metal layer includes a central circular area and an annular area surrounding the circular area and having a gap with the circular area;

[0041] 2) filled with polymer and piezoelectric particles;

[0042] Spin-coating polymer in the gap between the circular area of the metal layer and the annular area; filling the circular area of the metal layer with piezoelectric particles;

[0043] 3) bonding;

[0044] Align and bond the structures obtained in the two steps 2) up and down;

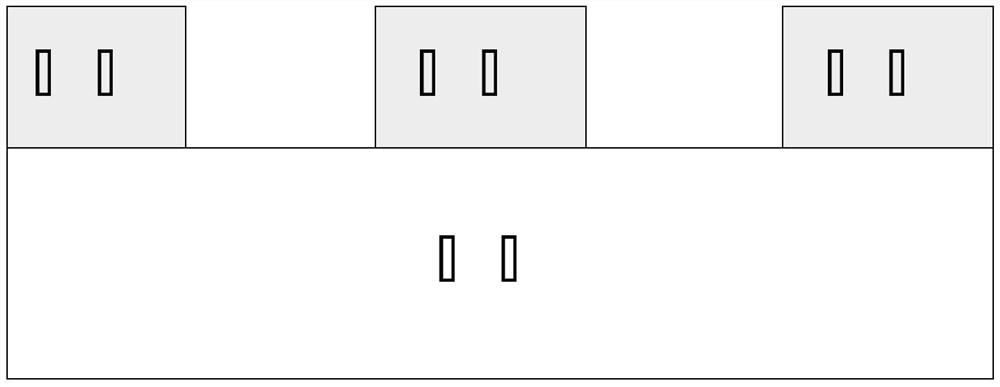

[0045] 4) Drill holes and fill them with metal.

[0046] Punch holes on the upper and lower silicon wafers of the structure obtained in step 3), and the punching position is located in the circular area of the center of the metal layer, and the depth of the punching reaches to the exposed m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com