Nano structure capable of improving asymmetric transmission and preparation method thereof

An asymmetric transmission and nanostructure technology, applied in the field of electromagnetic wave polarization state regulation, can solve the problem of small asymmetric transmission signal, and achieve the effects of outstanding asymmetric transmission performance, convenient preparation, reasonable and novel design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

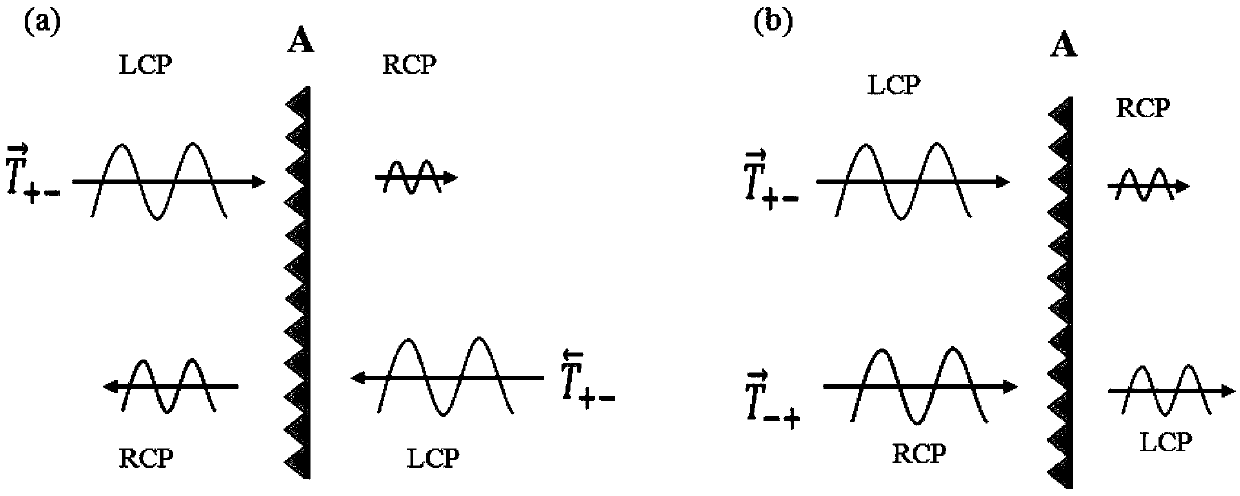

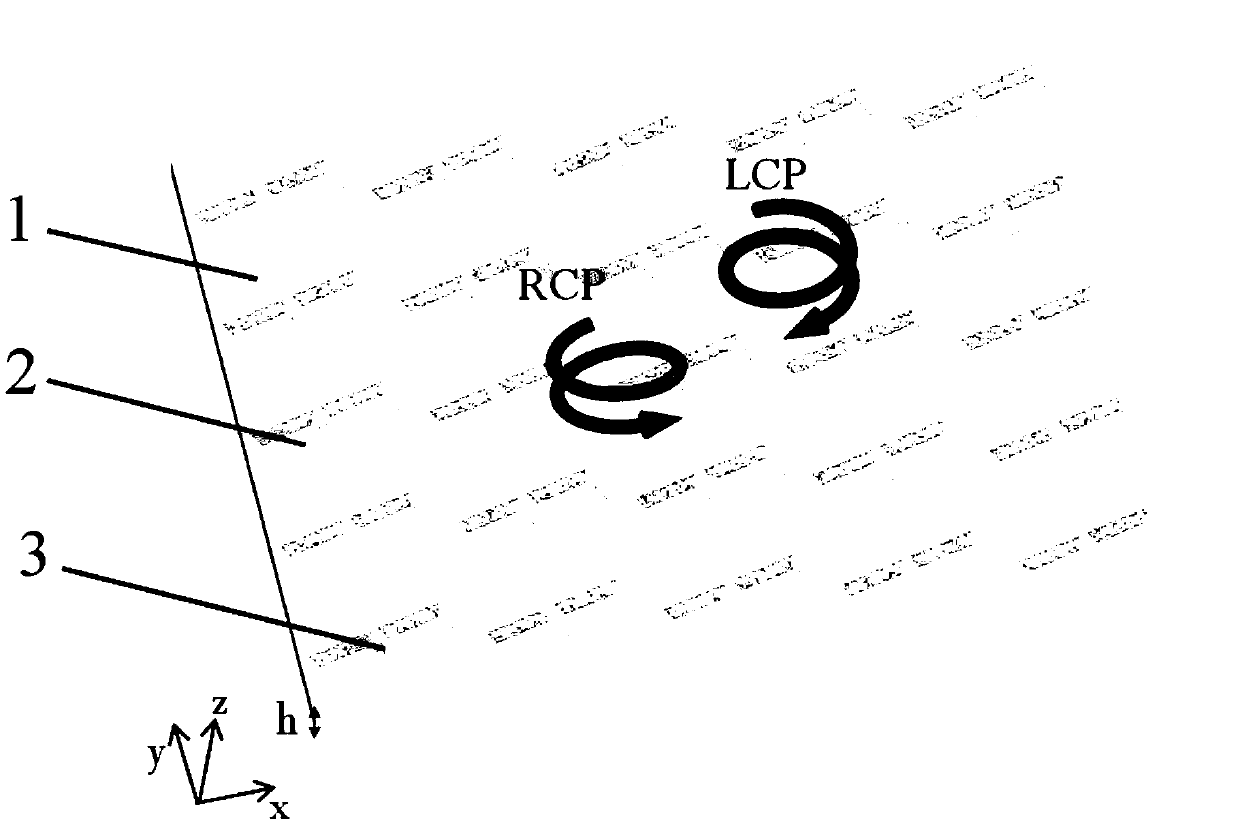

[0050] Such as figure 2 and image 3As shown, it is a nanostructure that can improve asymmetric transmission in the embodiment of the present application. The nanostructure that improves the asymmetric transmission has a simple preparation method and does not require repeated glue throwing. It can be formed with only one coating, but compared with the traditional single-layer artificial nanostructure, it can increase the asymmetric transmission signal by 5%.

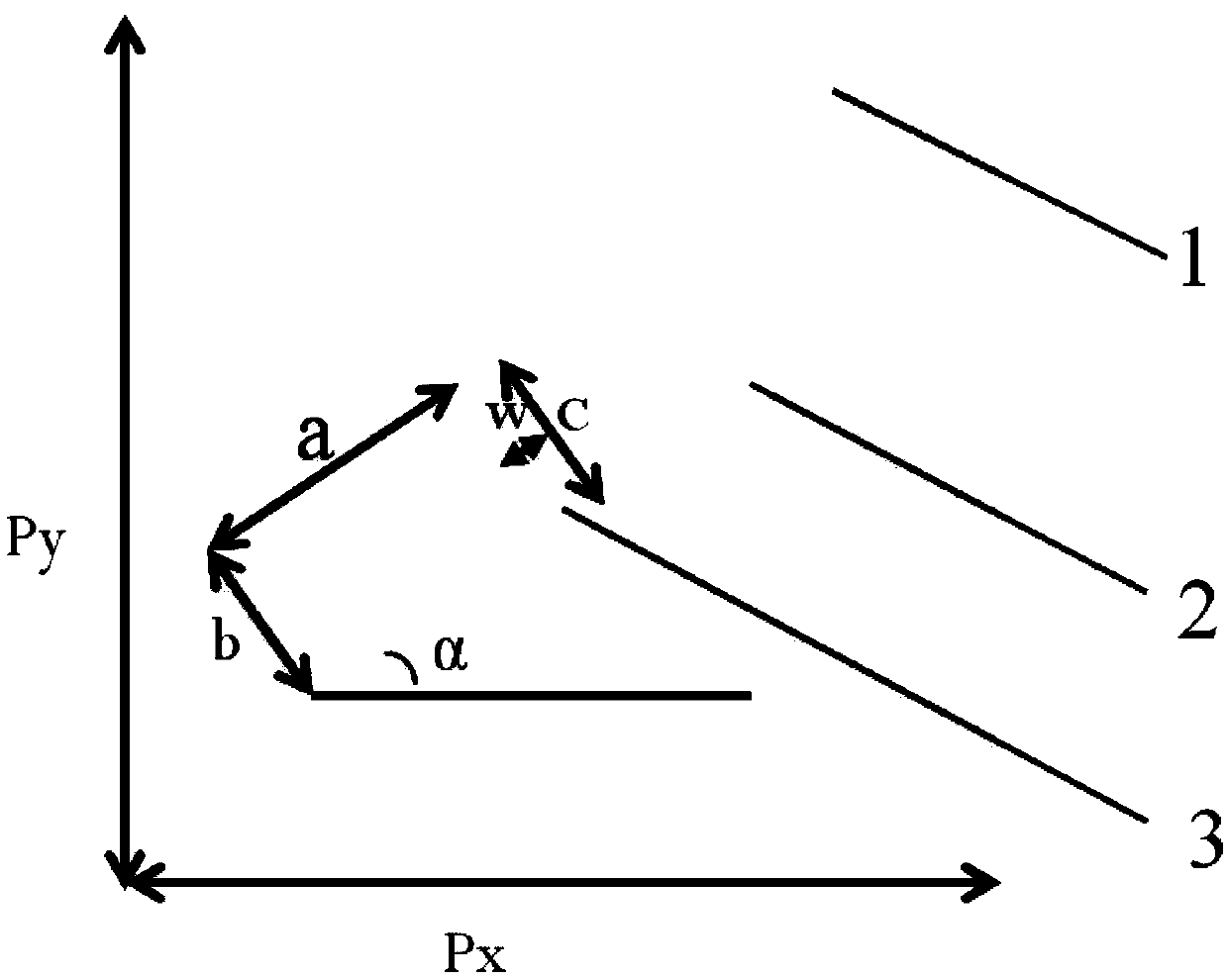

[0051] A nanostructure that can improve asymmetric transmission is formed by connecting a plurality of nanostructure units with the same structure in a rectangular periodic array. The nanostructure unit is composed of a metal film 1, and an inclined rectangular hole 2 is provided on the metal film 1. The rectangular hole 2 There is an angle α between the long side and the x-direction of the nanostructure unit.

[0052] The rectangular hole 2 also includes a connecting strip 3, the two ends of the connecting strip 3 ar...

Embodiment 2

[0060] Based on the nanostructure that can improve asymmetric transmission described in Example 1, the embodiment of the present application discloses a method for preparing a nanostructure that can improve asymmetric transmission. The specific steps are as follows:

[0061] Step 1, prepare the substrate: prepare the ITO glass substrate and wash and dry it;

[0062] Specifically, the thickness of the ITO glass is 1.0mm, and the length and width are 20.0mm×20.0mm. Put the prepared ITO glass into the washing solution to clean it. After ultrasonication with deionized water for 15 minutes, ultrasonication with acetone for 15 minutes, and alcohol ultrasonication for 15 minutes , and then ultrasonicated with deionized water for 5 minutes, and finally dried with a nitrogen gun and placed in a nitrogen cabinet for later use.

[0063] Step 2, apply photoresist: apply PMMA photoresist on the ITO glass substrate prepared in step 1 with a glue spinner;

[0064] Specifically, the thicknes...

Embodiment 3

[0079] Based on the nanostructure that can improve the asymmetric transmission disclosed in Example 1, the embodiment of the present application discloses a nanostructure that can improve the asymmetric transmission, using the 3D finite element method of COMSOL Multiphysics to realize the transmission of the nanostructure in the embodiment of the application and simulation of asymmetric transmission effects.

[0080] Such as figure 2 and image 3 As shown, the metal thin film 1 is preferably a gold material, the size of the rectangular hole 2: long side a=540nm, short side b=200nm, the angle α=22.5° between the long side of the rectangular hole 2 and the x direction of the nanostructure unit, and the length of the connecting strip 3 c=200nm, width w=17.32nm, nanostructure unit period: Px=Py=620nm, metal thin film 1 thickness h=80nm.

[0081] When the LCP and RCP are incident from the front of the structure, their polarization state conversion rates to the incident light are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com