Cobalt-chromium hydrotalcite-supported bismuth oxyiodide composite material and its preparation method and application

A technology of bismuth oxyiodide and composite materials, applied in chemical instruments and methods, water pollutants, chemical/physical processes, etc., can solve the problem of not much neutral red, achieve good light drop efficiency, and solve the effect of difficult recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Synthesis of Example 1 BiOI

[0030] 1. Take 0.006mol (2.91g) Bi(NO 3 ) 3 ·5H 2 O was dissolved in 160 mL of ethylene glycol, and stirred thoroughly at room temperature to obtain a white turbid liquid as A.

[0031] 2. Dissolve 0.006mol (0.996) KI in 160mL deionized water to form solution B. Add solution B to solution A dropwise using a constant pressure funnel, and keep stirring for 20min-40min.

[0032] 3. Then transfer it to a 500mL autoclave, and treat it at a constant temperature of 160°C for 18-24h.

[0033] 4. Suction filtration under reduced pressure and wash with deionized water and absolute ethanol three times respectively.

[0034] 5. Finally, dry at 65°C to obtain BiOI nanoparticles.

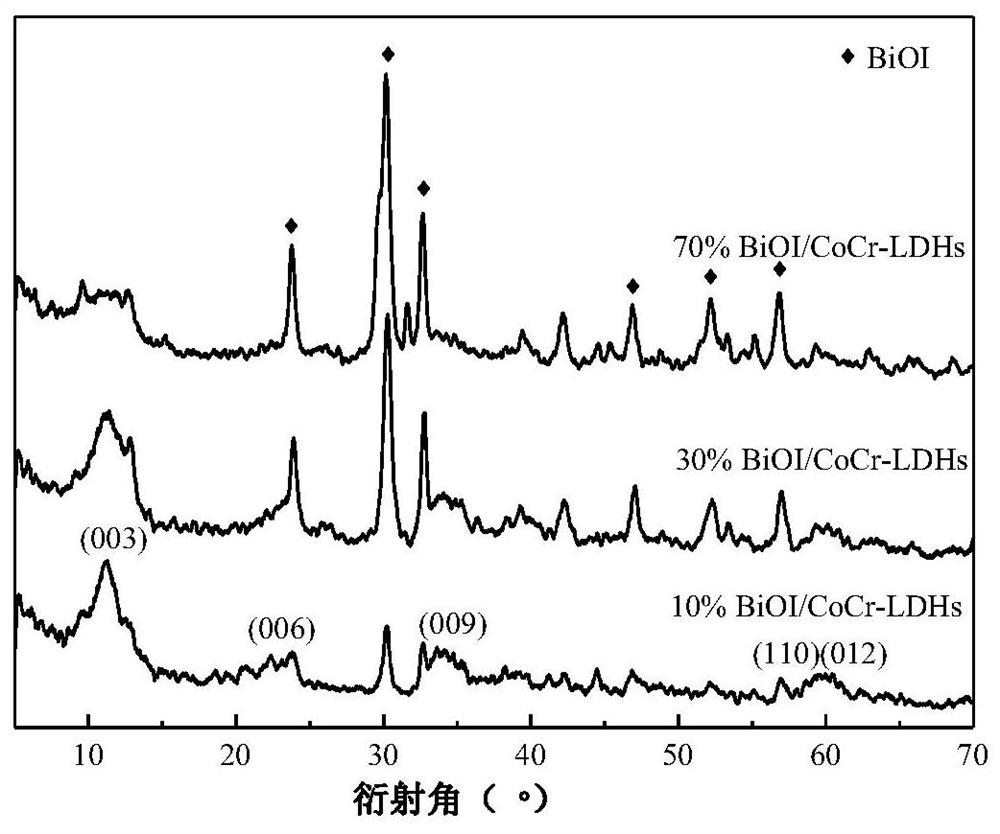

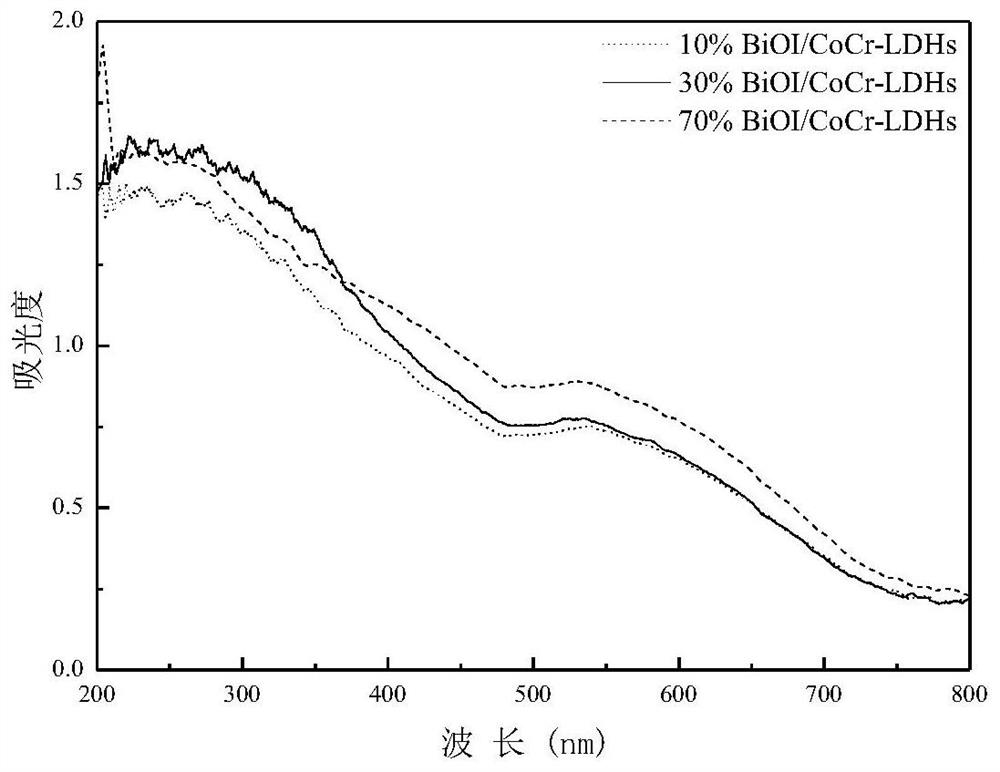

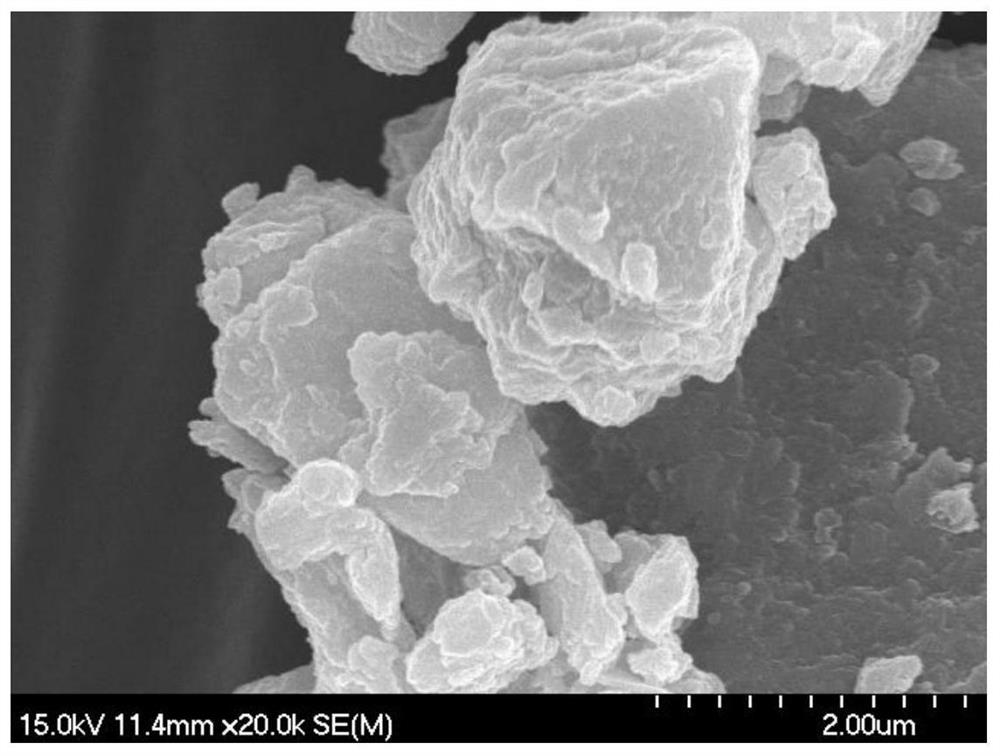

[0035] The cobalt-chromium hydrotalcite-supported bismuth oxyiodide composite material was experimentally prepared, in which the loading of bismuth oxyiodide was 10%-70%. The following examples respectively introduce materials with bismuth oxyiodide loading of 10%, 30% an...

Embodiment 2

[0036] Example 2 Synthesis of 10%BiOI / CoCr-LDHs

[0037] 1. Take 0.001mol (0.352g) of BiOI and pour it into a 500mL three-necked flask, and add 50mL of deionized water.

[0038] 2. Take Co(NO with a molar ratio of 3:1 3 ) 2 ·6H 2 O 0.03mol (8.73g) and Cr (NO 3 ) 2 9H 2 O 0.01mol (4.00g), dissolved in 100mL of deionized water to form solution A.

[0039] 3. Take 0.16mol (3.2g) NaOH and 0.01mol (0.05g) NaOH 2 CO 3 Dissolve in 100mL deionized water to make solution B.

[0040] 4. Double drop solutions A and B into a three-necked flask, keep stirring, and control the pH between 9-10.

[0041] 5. Continue to stir for 1 hour after dropping, and then crystallize at 65°C for 24 hours.

[0042] 6. Suction filtration and washing, drying in an oven at 65°C for 18 hours, and grinding to obtain the cobalt-chromium hydrotalcite-supported bismuth oxyiodide composite material, which is recorded as 10% BiOI / CoCr-LDHs.

Embodiment 3

[0043] The synthesis of embodiment 3 30%BiOI / CoCr-LDHs

[0044] 1. Take 0.003mol (1.056g) of BiOI and pour it into a 500mL three-necked flask, and add 50mL of deionized water.

[0045] 2. Take Co(NO with a molar ratio of 3:1 3 ) 2 ·6H 2 O 0.03mol (8.73g) and Cr (NO 3 ) 2 9H 2 O 0.01mol (4.00g), dissolved in 100mL of deionized water to form solution A.

[0046] 3. Take 0.16mol (3.2g) NaOH and 0.01mol (0.05g) NaOH2 CO 3 Dissolve in 100mL deionized water to make solution B.

[0047] 4. Double drop solutions A and B into a three-necked flask, keep stirring, and control the pH between 9-10.

[0048] 5. Continue to stir for 1 hour after dropping, and then crystallize at 65°C for 24 hours.

[0049] 6. Suction filtration and washing, drying in an oven at 65°C for 18 hours, and grinding to obtain the cobalt-chromium hydrotalcite-supported bismuth oxyiodide composite material, which is recorded as 30% BiOI / CoCr-LDHs.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com