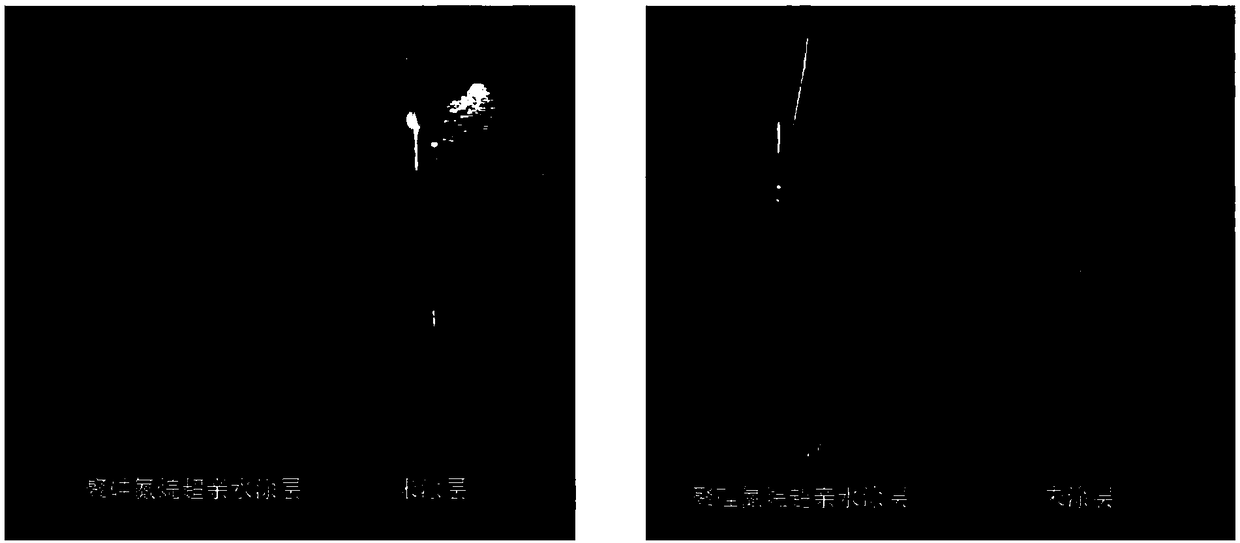

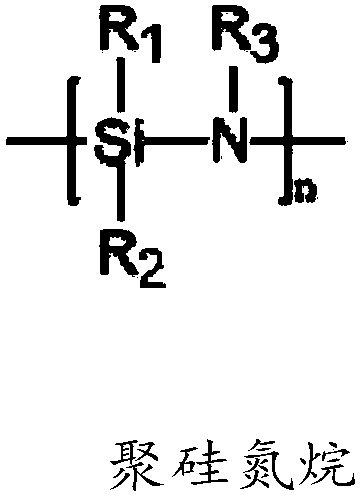

Long-acting super-hydrophilic polysilazane coating and preparation method thereof

A polysilazane, super-hydrophilic technology, used in coatings, antifouling/underwater coatings, devices for coating liquids on surfaces, etc., can solve problems such as the disappearance of super-hydrophilic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The preparation method of the long-acting superhydrophilic polysilazane coating provided by the present invention comprises the following steps:

[0022] Coating the polysilazane solution on the surface of the substrate, and then performing photocuring or combined photothermal curing to form a polysilazane coating, and then coating the surface treatment solution on the surface of the polysilazane coating, and then The substrate is heat treated.

[0023] The preparation process of the long-acting superhydrophilic polysilazane coating of the present invention is as follows: firstly, a superhydrophilic polysilazane solution is coated on the surface of the substrate, cured, and then used to contain a coupling agent and a surface active The surface treatment solution of the agent is grafted and cross-linked on the surface of the polysilazane, and then heat-treated to maintain its long-term hydrophilicity, thereby obtaining a super-hydrophilic polysilazane coating.

[0024] ...

Embodiment 1

[0061] The long-acting superhydrophilic polysilazane coating on the tinplate in the present embodiment is prepared by the following method:

[0062] The formula of polysilazane solution is as follows: 10 parts of polysilazane, 89 parts of butyl acetate, 1 part of zinc oxide, 0.05 parts of dispersant S-2107, catalyst 4,4'-trimethylenebis(1-methylpiperidine ) 0.05 part, photoinitiator 1173 0.05 part.

[0063] The formula of the surface treatment solution is as follows: 5 parts of betaine, 95 parts of water, 1 part of citric acid, and 0.5 part of coupling agent KH570.

[0064] The polysilazane solution is spray-coated on the cleaned and dried tinplate substrate, baked in an oven at 100°C for 5 minutes, the solvent is removed, and then cured by photothermal coupling for 10 minutes; then the cured tinplate is dipped in Put it in the surface treatment solution for 10 minutes, take it out and place it in an oven to continue baking and solidification to obtain super-hydrophilic tinpl...

Embodiment 2

[0068] The long-acting superhydrophilic polysilazane coating on the glass in this embodiment is prepared by the following method:

[0069] The formula of polysilazane solution is as follows: 10 parts of polysilazane, 89 parts of xylene, 1 part of titanium dioxide, 0.05 parts of dispersant S-2107, catalyst 1,8-diazabicyclo[5.4.0]-7-undeca 0.05 part of carbene, 0.05 part of photoinitiator 184.

[0070] The formula of the surface treatment mixed solution is as follows: 3 parts of tartrate, 5 parts of disodium trihydroxysilylpropionate, 92 parts of water, 1 part of citric acid, and 0.5 part of coupling agent X-12-1135.

[0071] The polysilazane solution is sprayed on the cleaned and dried glass substrate, baked in an oven at 100°C for 5 minutes to remove most of the solvent, and then cured by light for 10 minutes; then apply the surface treatment solution on the cured In the glass, put it in an oven and dry to obtain superhydrophilic glass. After washing and wiping with water fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water contact angle | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com