Method for producing nano negative ion vehicle interior fabric with improved structure

A technology of nano-anions and improved structure, which is applied in the processing of textile materials, chemical instruments and methods, and auxiliary lamination operations. The effect of high efficiency, increasing the mixing range, and speeding up the speed of ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

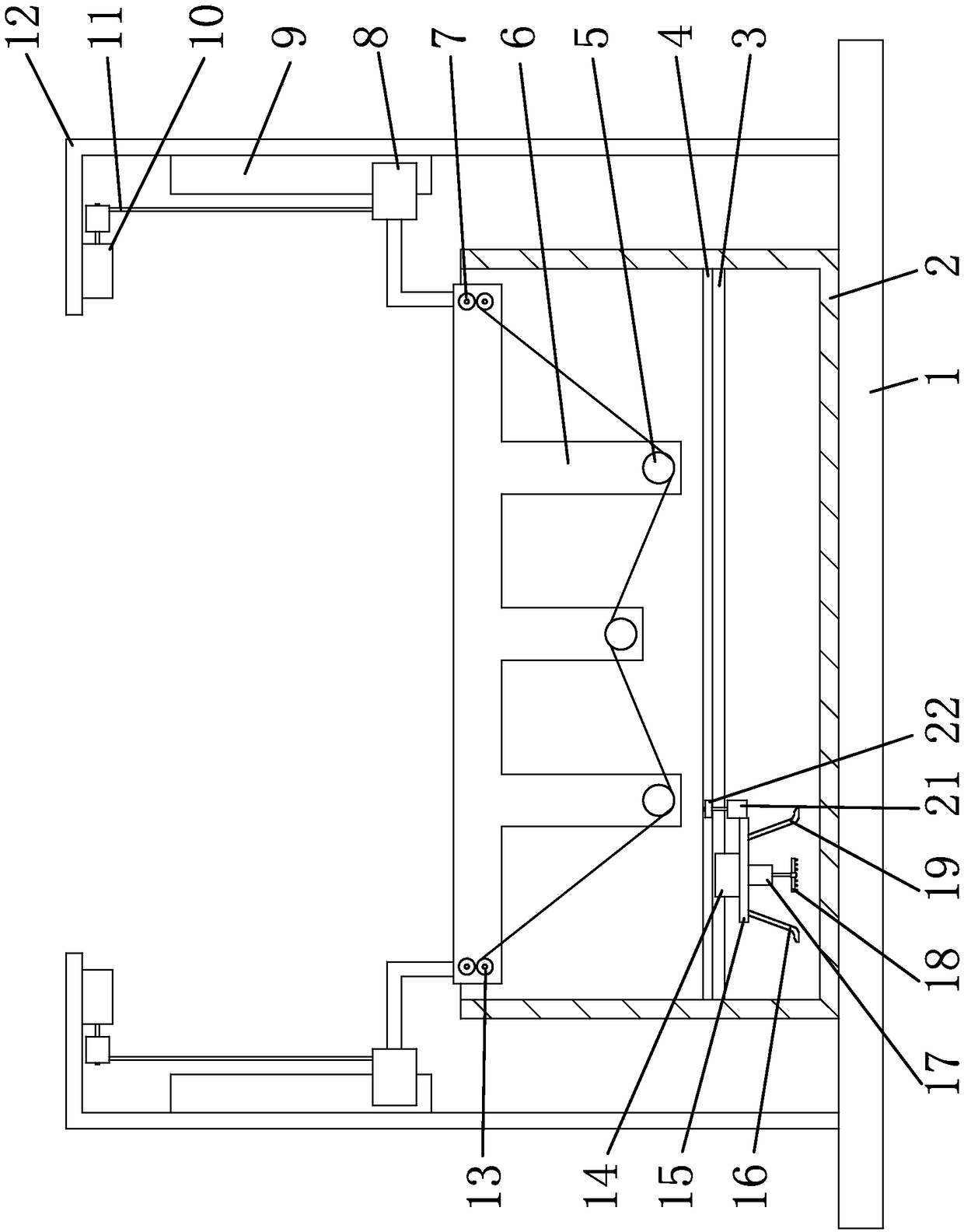

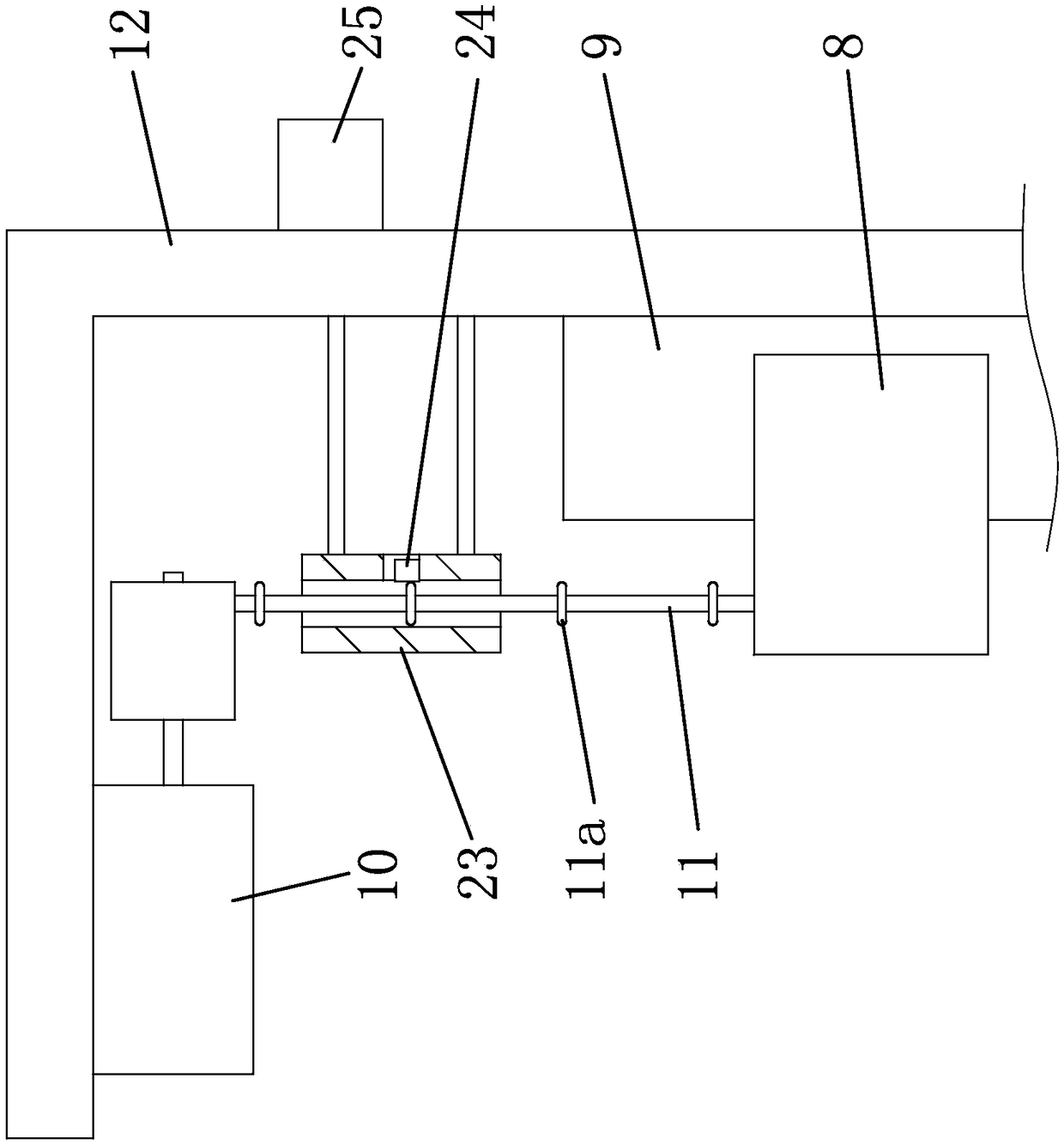

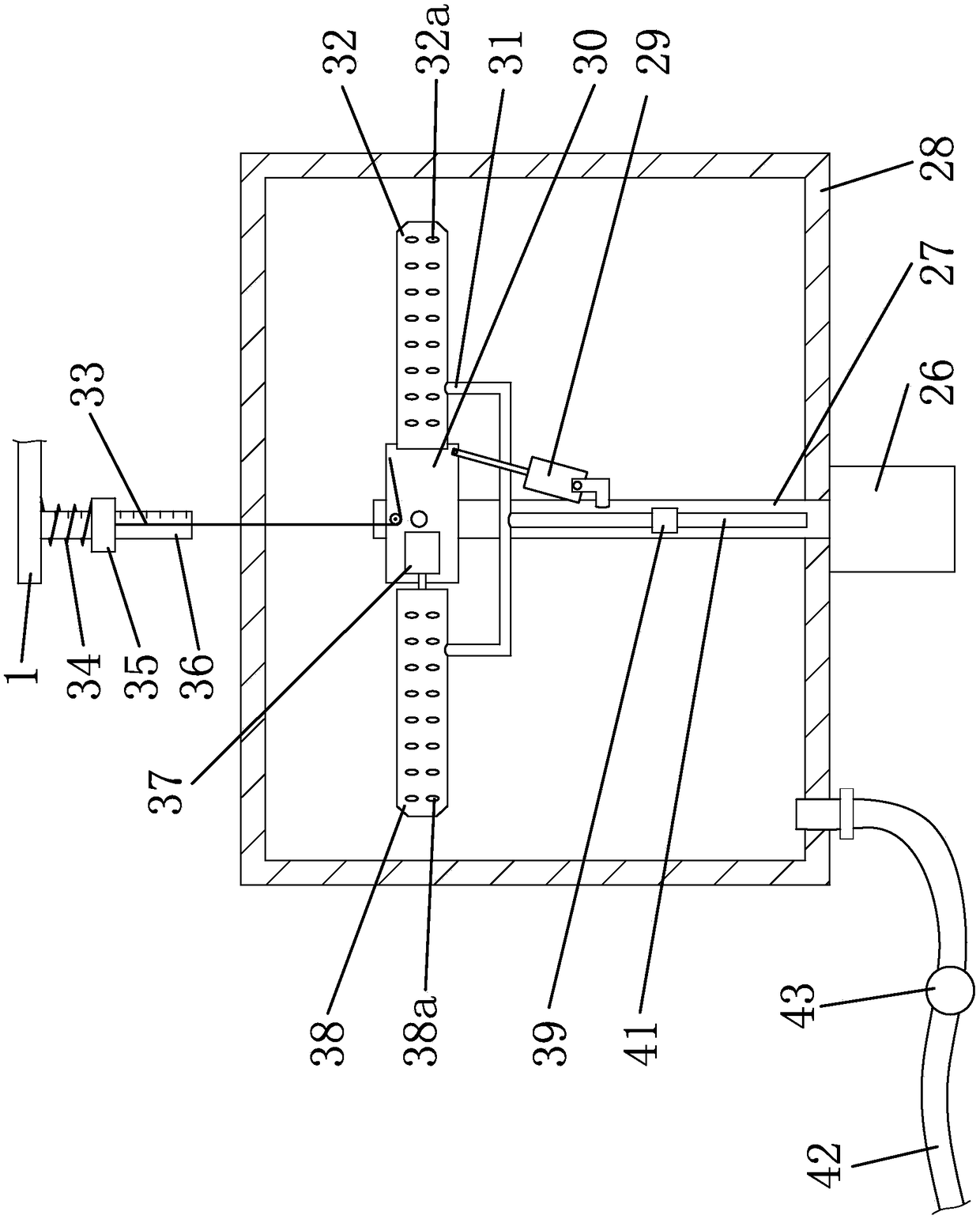

[0049] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0050] The preparation method of the nano-anion automotive interior fabric of this improved structure comprises the steps:

[0051] a. Disperse 8-24 parts of nano tourmaline powder, 3-8 parts of dispersant, 3-7 parts of coupling agent, 2-5 parts of antioxidant, 2-5 parts of antistatic agent and 60-80 parts of water, and disperse them by ultrasonic waves Process to obtain finishing liquid; In the present embodiment, with 16 parts of nano tourmaline powder, 5 parts of dispersing agent, 4 parts of coupling agent, 3 parts of antioxidant, 3 parts of antistatic agent and 70 parts of water, through ultrasonic dispersion treatment, Obtain finishing liquid; Nano tourmaline powder adopts the existing product that can buy on the mark...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com