Injectable early-strength ultrahigh-toughness mortar concrete system and preparation method thereof

A technology of mortar concrete with ultra-high toughness, which is applied in the field of fiber reinforced mortar concrete, which can solve the problems of low matrix bond strength, low early strength, and difficulty in spraying construction, etc., to improve product competitiveness, strengthen interface bond performance, Effect of reducing material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

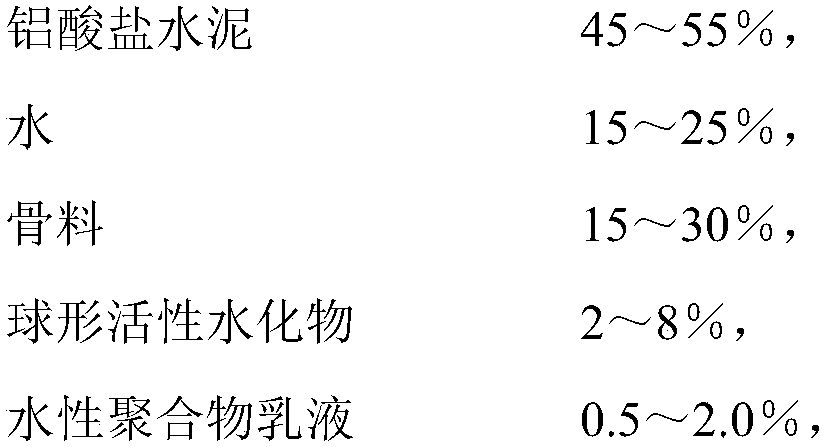

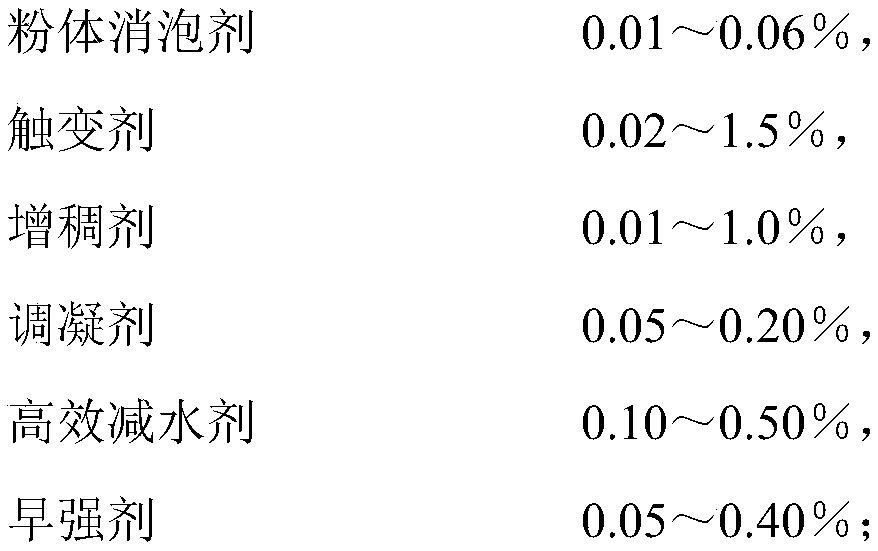

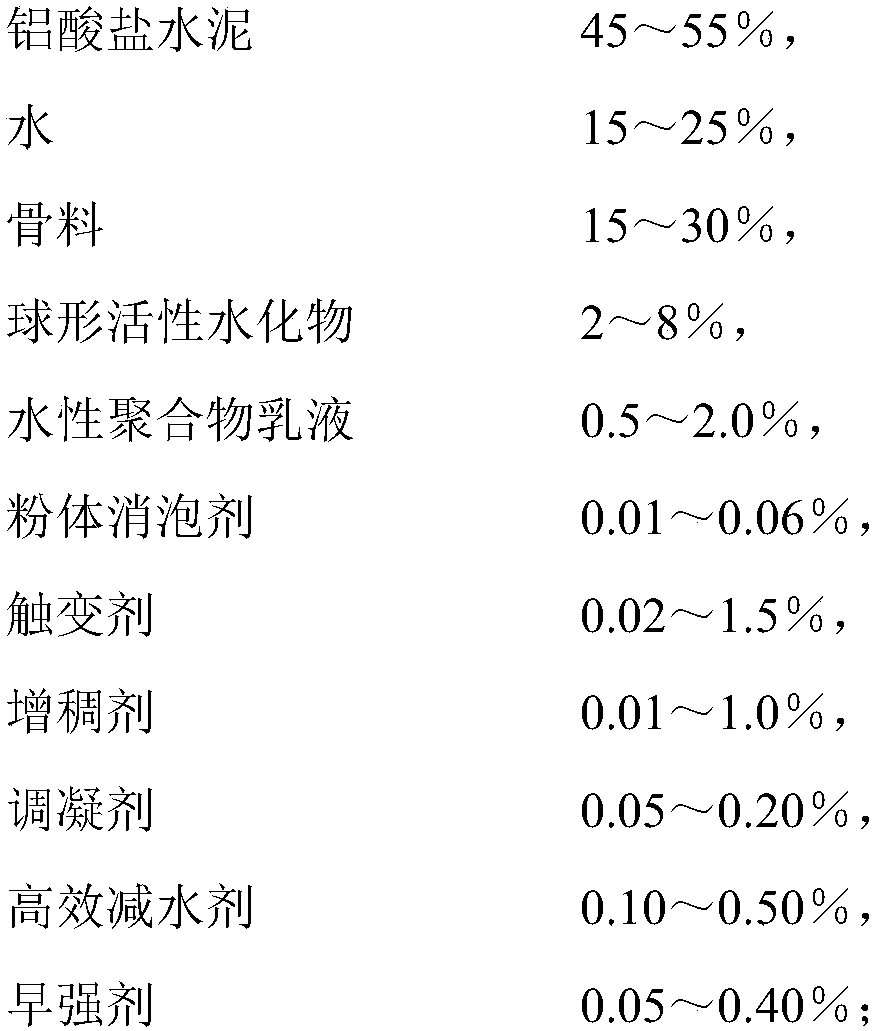

[0054] A kind of mortar concrete of the present invention, its proportioning is as follows:

[0055] Sulphoaluminate cement: 45%

[0056] Aggregate: 30%

[0057] Spherical Active Hydrate: 4%

[0058] Water-soluble polymer emulsion: 0.5%

[0059] Silicone powder defoamer: 0.01%

[0060] Thixotropic agent: 1.5%

[0061] Thickener: 0.01%

[0062] Coagulant: 0.05%

[0063] Superplasticizer: 0.50%

[0064] Early strength agent: 0.05%;

[0065] The mortar concrete is mixed with fiber: polyoxymethylene fiber 40kg / m 3 , diameter: 300 microns; length: 15 mm, tensile strength: 940MPa, modulus of elasticity: 20GPa;

[0066] Accurately measure the above-mentioned materials and add them to the dry powder mortar automatic production equipment. After mixing evenly, measure and seal the moisture-proof packaging for later use.

Embodiment 2

[0068] A kind of mortar concrete of the present invention, its proportioning is as follows:

[0069] Sulphoaluminate cement: 55%

[0070] Aggregate: 15%

[0071] Spherical Active Hydrate: 8%

[0072] Water-soluble polymer emulsion: 2.0%

[0073] Polyether powder defoamer: 0.06%

[0074] Thixotropic agent: 0.02%

[0075] Thickener: 1.0%

[0076] Coagulant regulator: 0.20%

[0077] Superplasticizer: 0.10%

[0078] Early strength agent: 0.40%

[0079] The mortar concrete is mixed with fiber: polyvinyl alcohol fiber 10kg / m 3 , diameter: 30 microns; length: 6 mm, tensile strength: 1600MPa, modulus of elasticity: 40GPa;

[0080] Accurately measure the above-mentioned materials and add them to the dry powder mortar automatic production equipment. After mixing evenly, measure and seal the moisture-proof packaging for later use.

Embodiment 3

[0082] A kind of mortar concrete of the present invention, its proportioning is as follows:

[0083] Sulphoaluminate cement: 40%

[0084] Aggregate: 22.5%

[0085] Spherical Active Hydrate: 2%

[0086] Water-soluble polymer emulsion: 1.5%

[0087] Silicone powder defoamer: 0.03%

[0088] Thixotropic agent: 1.0%

[0089] Thickener: 0.45%

[0090] Coagulant: 0.15%

[0091] Superplasticizer: 0.35%

[0092] Early strength agent: 0.25%

[0093] The mortar concrete is mixed with fibers: polyvinyl alcohol fibers and polyoxymethylene fibers are 20 and 12 kg / m respectively 3 , wherein polyvinyl alcohol fiber diameter: 40 microns; length: 8 mm, tensile strength: 1540 MPa, modulus of elasticity: 40 GPa; polyoxymethylene fiber diameter: 200 microns; length: 12 mm, tensile strength: 1000 MPa, Elastic modulus: 24GPa;

[0094] Accurately measure the above-mentioned materials and add them to the dry powder mortar automatic production equipment. After mixing evenly, measure and seal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com