Low-elastic-modulus flexible ultrahigh-toughness mortar concrete system and preparation method thereof

A mortar concrete, ultra-high toughness technology, used in solid waste management, climate sustainability, sustainable waste treatment, etc. problems, to achieve the effect of improving product competitiveness, reducing material costs, and ensuring time windows

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

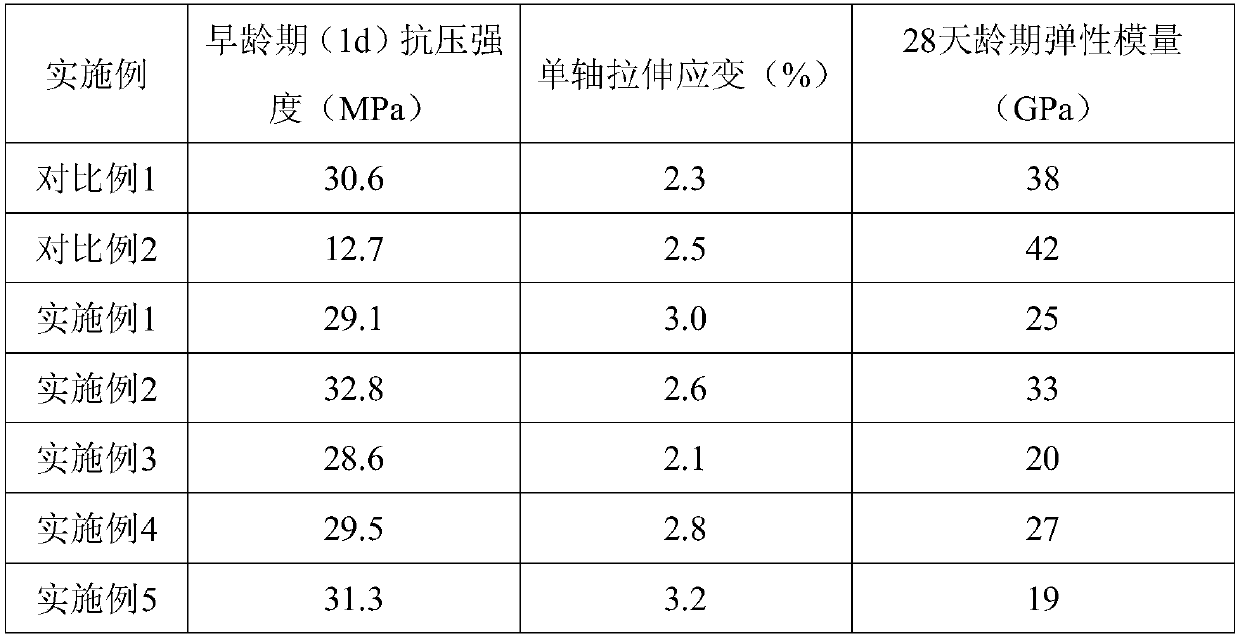

Embodiment 1

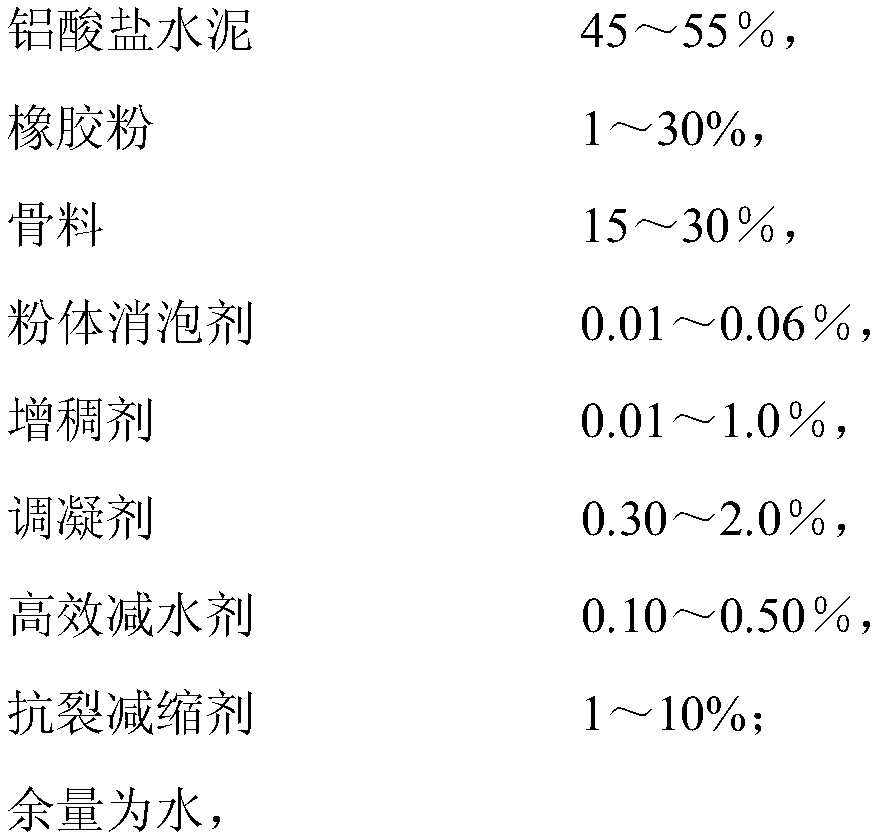

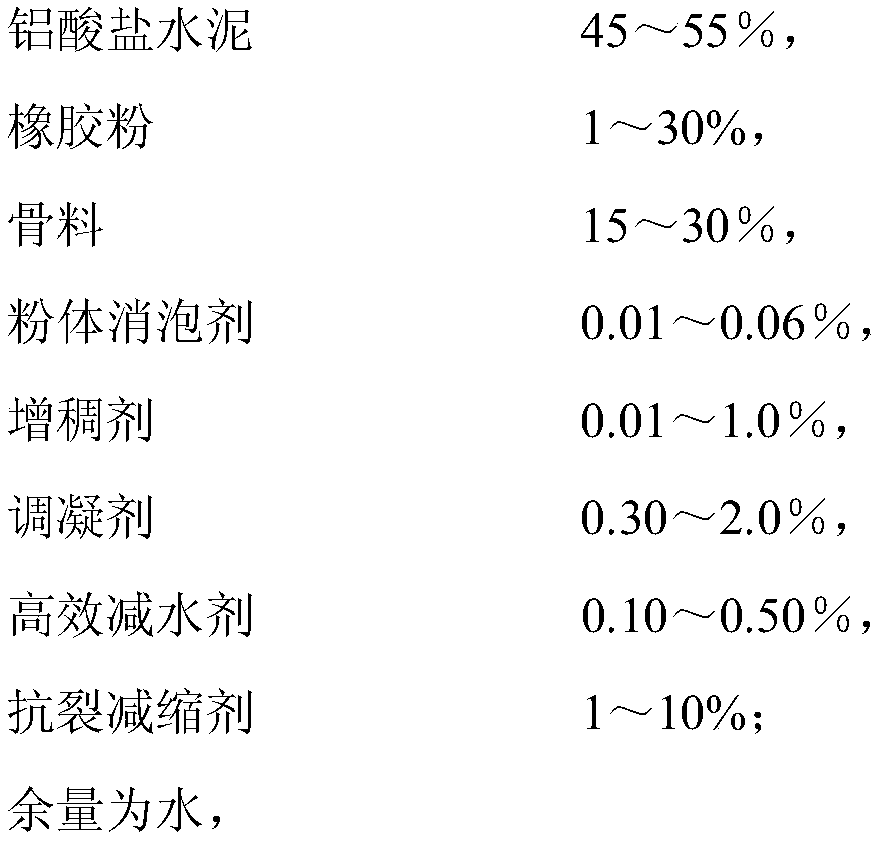

[0061] A kind of mortar concrete of the present invention, its proportioning is as follows:

[0063] Natural rubber powder: 10%

[0064] Aggregate: 30%

[0065] Silicone powder defoamer: 0.01%

[0066] Cellulose ether thickener: 0.01%

[0067] Borax coagulant: 0.30%

[0068] Polycarboxylate superplasticizer: 0.50%

[0069] Calcium oxide anti-crack and shrinkage reducer: 5.00%

[0070] The remainder is water;

[0071] The particle size of the natural rubber powder is 100 mesh, the shape of the particle is spherical, and the continuity of the particle size satisfies the normal distribution; the surface of the rubber powder is untreated.

[0072] The mortar concrete is mixed with fiber: polyoxymethylene fiber 40kg / m 3 , wherein the fiber dosage of 30 microns in diameter and 6 mm in length is 25 kg, tensile strength: 1500 MPa, modulus of elasticity: 30 GPa; balance is 300 microns in diameter, 15 mm in length, tensile strength: 940 MPa, modulu...

Embodiment 2

[0075] A kind of mortar concrete of the present invention, its proportioning is as follows:

[0076] Sulphoaluminate cement: 55%

[0077] Butadiene rubber powder: 30%

[0078] Aggregate: 15%

[0079] Polyether powder defoamer: 0.06%

[0080] Cellulose ether thickener: 1.0%

[0081] Borax coagulant: 2.00%

[0082] Polycarboxylate powder superplasticizer: 0.10%

[0083] Calcium oxide anti-crack and shrinkage reducer: 10.00%

[0084] The remainder is water;

[0085] The equivalent particle size of the butadiene rubber powder is 20 meshes, and the shape of the particles is irregular, and the continuity of the particle size satisfies a normal distribution; the surface of the rubber powder is untreated.

[0086] The mortar concrete is mixed with fiber: polyvinyl alcohol fiber 10kg / m 3 , diameter: 30 microns; length: 6 mm, tensile strength: 1600MPa, modulus of elasticity: 40GPa;

[0087] Accurately measure the above-mentioned materials and add them to the dry powder mortar a...

Embodiment 3

[0089] A kind of mortar concrete of the present invention, its proportioning is as follows:

[0090] Aluminate cement: 50.00%

[0091] SBR powder: 1.00%

[0092] Aggregate: 30.00%

[0093] Silicone powder defoamer: 0.03%

[0094] Cellulose ether thickener: 0.05%

[0095] Borate coagulant: 1.00%

[0096] Polycarboxylate superplasticizer: 0.25%

[0097] Calcium oxide anti-crack and shrinkage reducer: 1.0%

[0098] The remainder is water;

[0099] The equivalent particle size of the styrene-butadiene rubber powder is 500 mesh, and the particle shape is irregular, and the continuity of the particle size satisfies a normal distribution; the surface of the rubber powder is treated with a surface modifier after activation.

[0100] The mortar concrete is mixed with fibers: polyvinyl alcohol fibers and polyoxymethylene fibers are 20 and 12 kg / m respectively 3 , wherein polyvinyl alcohol fiber diameter: 40 microns; length: 8 mm, tensile strength: 1540 MPa, elastic modulus: 40 G...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com