Surface anti-icing material and preparation method thereof

An anti-icing and base material technology, applied in textiles and papermaking, fiber treatment, physical treatment, etc., can solve the problem of surface ice layer being difficult to remove, and achieve the effect of easy sliding, water freezing, mild conditions and low adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

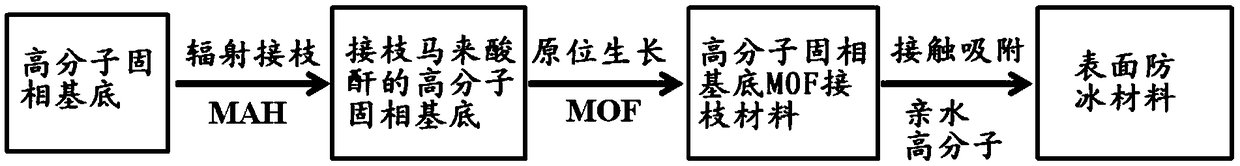

[0039] The invention provides a method for preparing a surface anti-icing material, comprising the following steps:

[0040] a) Radiation grafting maleic anhydride on the surface of the polymer solid phase base material to obtain the material of grafted maleic anhydride;

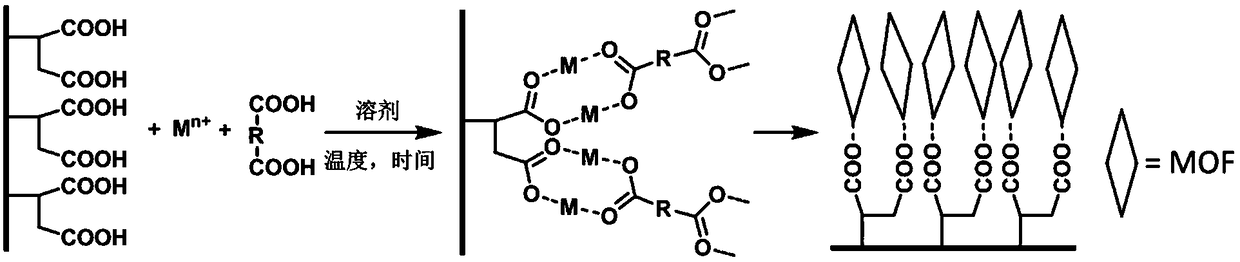

[0041] b) immersing the grafted maleic anhydride material obtained in step a) in a mixed solution of a metal salt and an organic ligand, and growing in situ to obtain a MOF grafted material;

[0042] c) contacting and adsorbing the MOF grafted material obtained in step b) with a solution of a hydrophilic polymer, and drying to obtain a surface anti-icing material.

[0043] see figure 1 , figure 1 The flow chart of the preparation of the surface anti-icing material provided by the embodiment of the present invention.

[0044] In the invention, firstly, maleic anhydride is radiated and grafted on the surface of the polymer solid phase base material to obtain the grafted maleic anhydride material. In the pr...

Embodiment 1

[0090] (1) Take 10g of non-woven material (PP), wash it with acetone and dry it, put it into a closed container to evacuate it, put it into a radiation source for irradiation, the irradiation temperature is 30°C, and the radiation dose rate is 3kGy / h, The radiation dose is 30kGy to obtain the irradiated base material; then add maleic anhydride to a three-necked flask connected with a stirring paddle, and heat it at 80°C to melt to obtain a reaction solution; then use a glass tube to feed the reaction Below the liquid level, nitrogen gas was introduced. After 15 minutes, the above-mentioned irradiated base material was added to the flask to be completely submerged in the above-mentioned reaction solution, and the reaction was stopped after 6 hours at 105 ° C. The solid product was filtered out, and the product was tested. After extracting, washing and drying, the grafted maleic anhydride material is obtained.

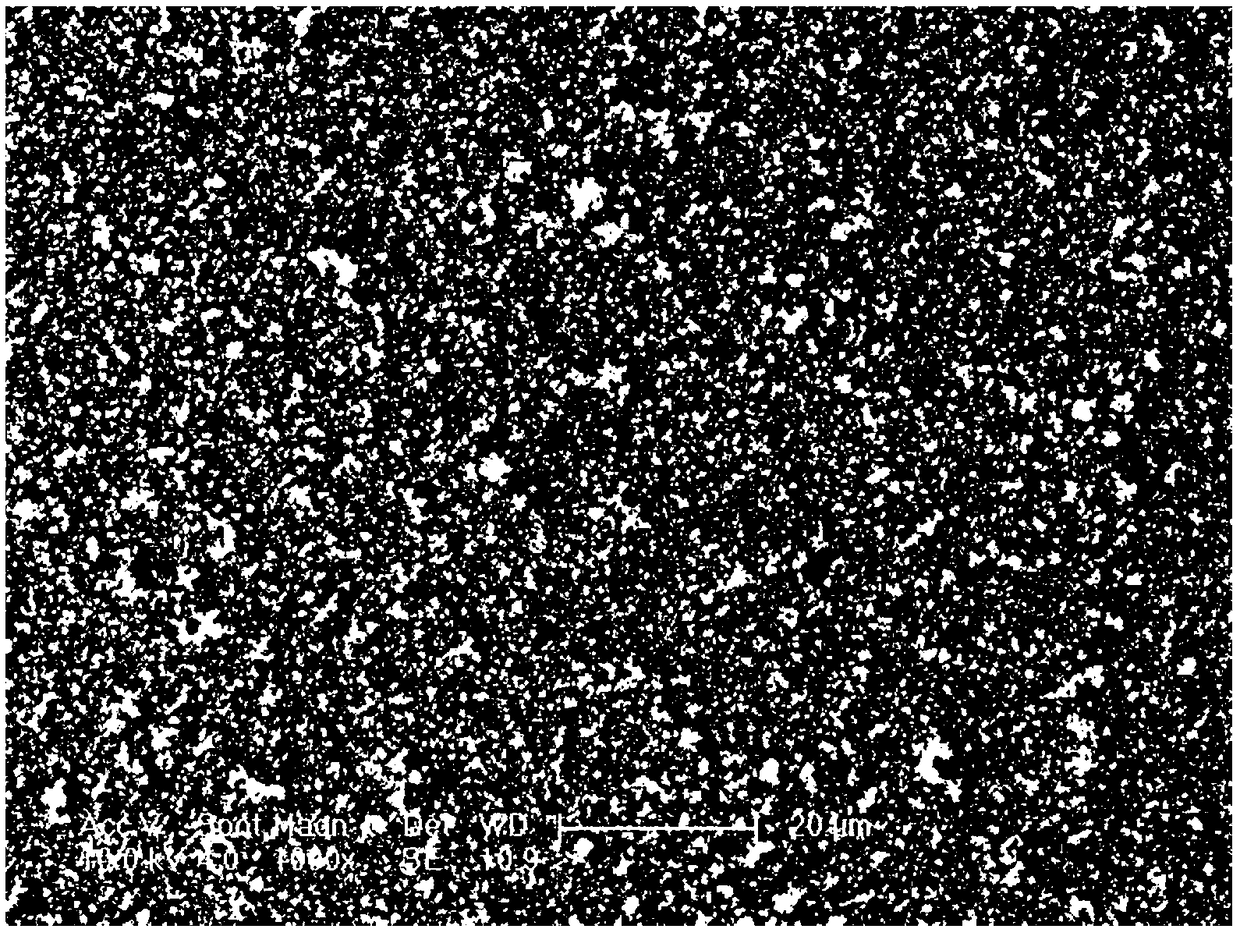

[0091] (2) the ferric chloride of 3 weight parts and the terephthal...

Embodiment 2

[0096] (1) Take 10g of ultra-high molecular weight polyethylene (UHMWPE), wash it with acetone and dry it, put it into a closed container to evacuate it, put it into a radiation source for irradiation, the irradiation temperature is 30°C, and the radiation dose rate is 0.5kGy / h, the radiation dose is 20kGy, to obtain the irradiated base material; then add maleic anhydride in the three-necked flask connected with the stirring paddle, and heat it to melt at 70°C to obtain the reaction solution; then use a glass tube Pass the reaction liquid below the liquid level, and pass nitrogen gas. After 15 minutes, add the above-mentioned irradiated base material into the flask to completely immerse in the above-mentioned reaction liquid, stop the reaction at 100°C for 7 hours, and filter out the solid product. The product is extracted, washed and dried to obtain the grafted maleic anhydride material.

[0097] (2) the ferric chloride of 3 weight parts and the terephthalic acid of 1 weight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com