Method for rapidly oxidizing Fe<2+> in acid process in-situ leaching uranium mining solution by psychrotolerant and acidophilic bacteria at low temperature

A technology for in-situ leaching of uranium and acidophilic bacteria, which is applied to the field of Fe2+ in the uranium mining solution of the bacterial rapid oxidation acid method, which can solve the problems of reduced oxidation activity of mesophilic bacteria, inability to meet industrial production, and low ambient temperature of the in-situ leaching solution. , to achieve the effect of saving production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

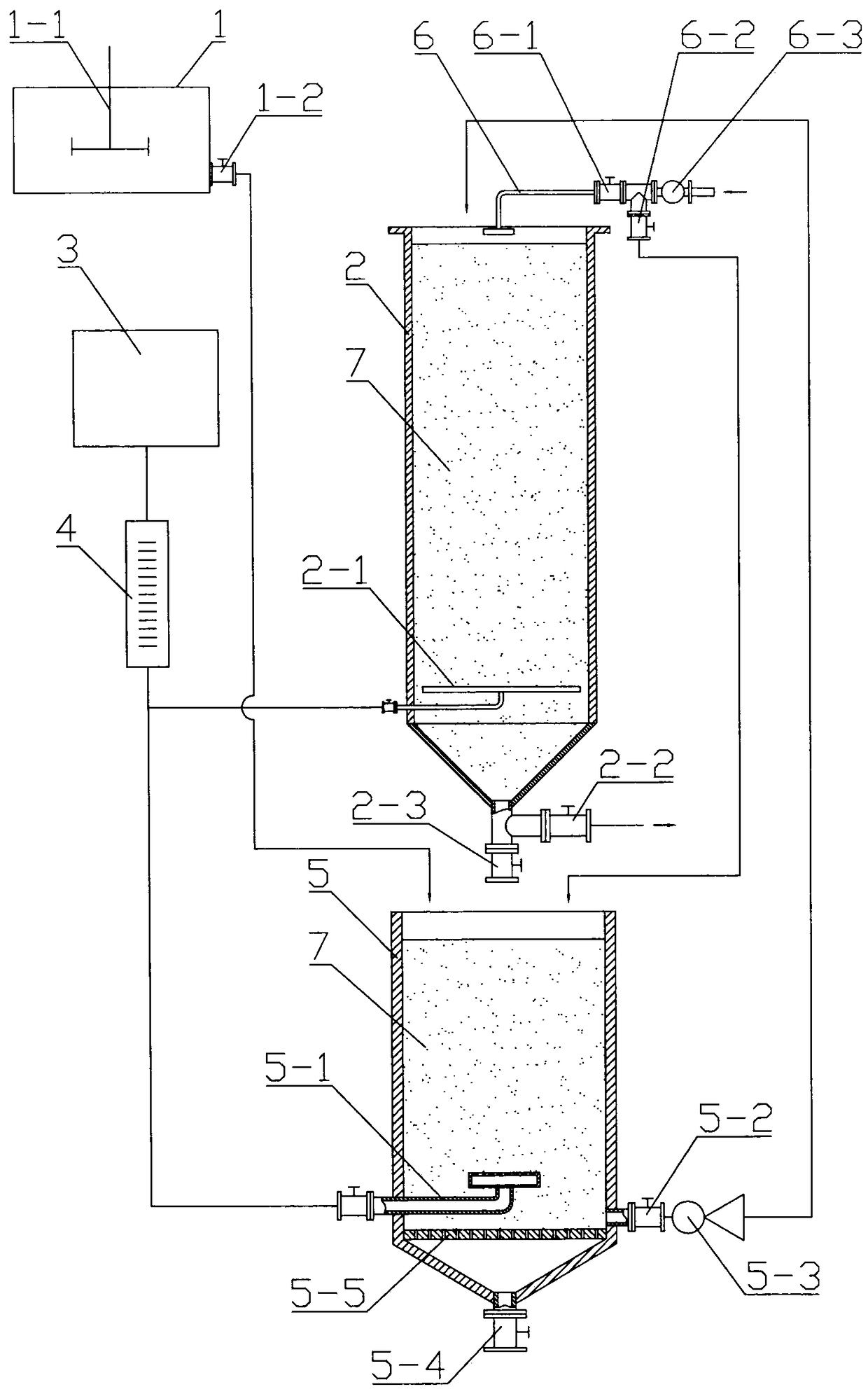

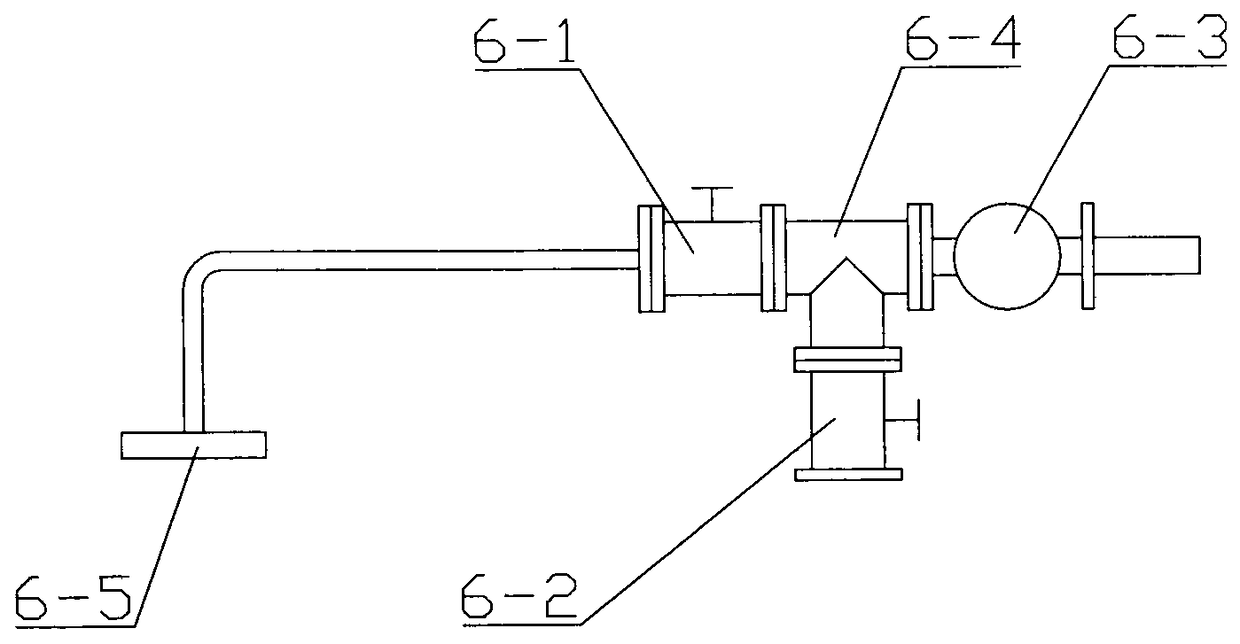

[0033]Example 1. Low-temperature rapid oxidation of Fe in uranium mining solution by psychrophilic acidophilus in-situ leaching by acid method 2+ The method uses cold-resistant acidophilic thiobacillus as the oxidant, uses bio-ceramsite with strong acid resistance and large specific surface area as the carrier of the bacterial membrane, and uses a moving bed bioreactor to immobilize the bacteria to achieve rapid and continuous oxidation adsorption. Fe in tail fluid 2+ the goal of.

[0034] The specific operation steps are as follows:

[0035] A. Activation of cold-resistant acidophilus bacteria liquid

[0036] Adopt 9K medium as culture medium, wherein, 9K medium composition is: (NH 4 ) 2 SO 4 3000 mg / L, K 2 HPO 4 500mg / L, KCl 100mg / L, MgSO 4 500 mg / L, Ca(NO 3 ) 2 10mg / L.

[0037] First, add 9K medium into the solution preparation tank 1, adjust the pH value to 1, then add the psychroacidophilic thiobacillus liquid into the solution preparation tank 1, inoculate...

Embodiment 2

[0055] Embodiment two, with respect to embodiment one:

[0056] In step A, adjust the pH value of the 9K medium to 2.0, and inoculate at a volume fraction of 25%, the stirring temperature is 20°C, the rotation speed of the agitator 1-2 is 180r / min, and the culture in the container is measured every 8h The reduction potential of the solution, when the reduction potential reaches 550 mV, the activated psychroacidophilus bacterial solution is obtained.

[0057] In the C1 step, the composition of the adsorption tail liquid is: SO 4 2- 10000 mg / L, PO 4 3- 25 mg / L, Cl - 500 mg / L, Fe 2 + 1000 mg / L, ∑Fe 1500 mg / L, Ca 2+ 500 mg / L, Mg 2+ 500 mg / L, NH 4 + 100 mg / L, K + 100mg / L, Na + 500 mg / L, the activated psychroacidophilus liquid and the adsorption tail liquid were inoculated at a volume fraction of 30%.

[0058] In the C2 step, the ventilation rate per hour is 0.5 times of the volume of the carrier regeneration tank 5, and the reduction potential of the culture s...

Embodiment 3

[0062] Embodiment three, with respect to embodiment one:

[0063] In step A, adjust the pH value of the 9K medium to 2.5, and inoculate at a volume fraction of 50%, the stirring temperature is 35°C, the speed of the stirrer 1-2 is 200r / min, and the culture in the container is measured every 10h The reduction potential of the liquid, when the reduction potential reaches 600 mV, the activated cold-resistant acidophilus bacterial liquid is obtained.

[0064] In the C1 step, the composition of the adsorption tail liquid is: SO 4 2- 15000 mg / L, PO 4 3- 50 mg / L, Cl - 1000 mg / L, Fe 2+ 2000 mg / L, ∑Fe 3500 mg / L, Ca 2+ 1000 mg / L, Mg 2+ 1000 mg / L, NH 4 + 200 mg / L, K + 200mg / L, Na + 1000 mg / L, the activated psychroacidophilus liquid and the adsorption tail liquid were inoculated at a volume fraction of 50%.

[0065] In the C2 step, the ventilation rate per hour is 1 time of the volume of the carrier regeneration tank 5, and the reduction potential of the culture solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com