Zinc powder consumption reduction method for zinc hydrometallurgy

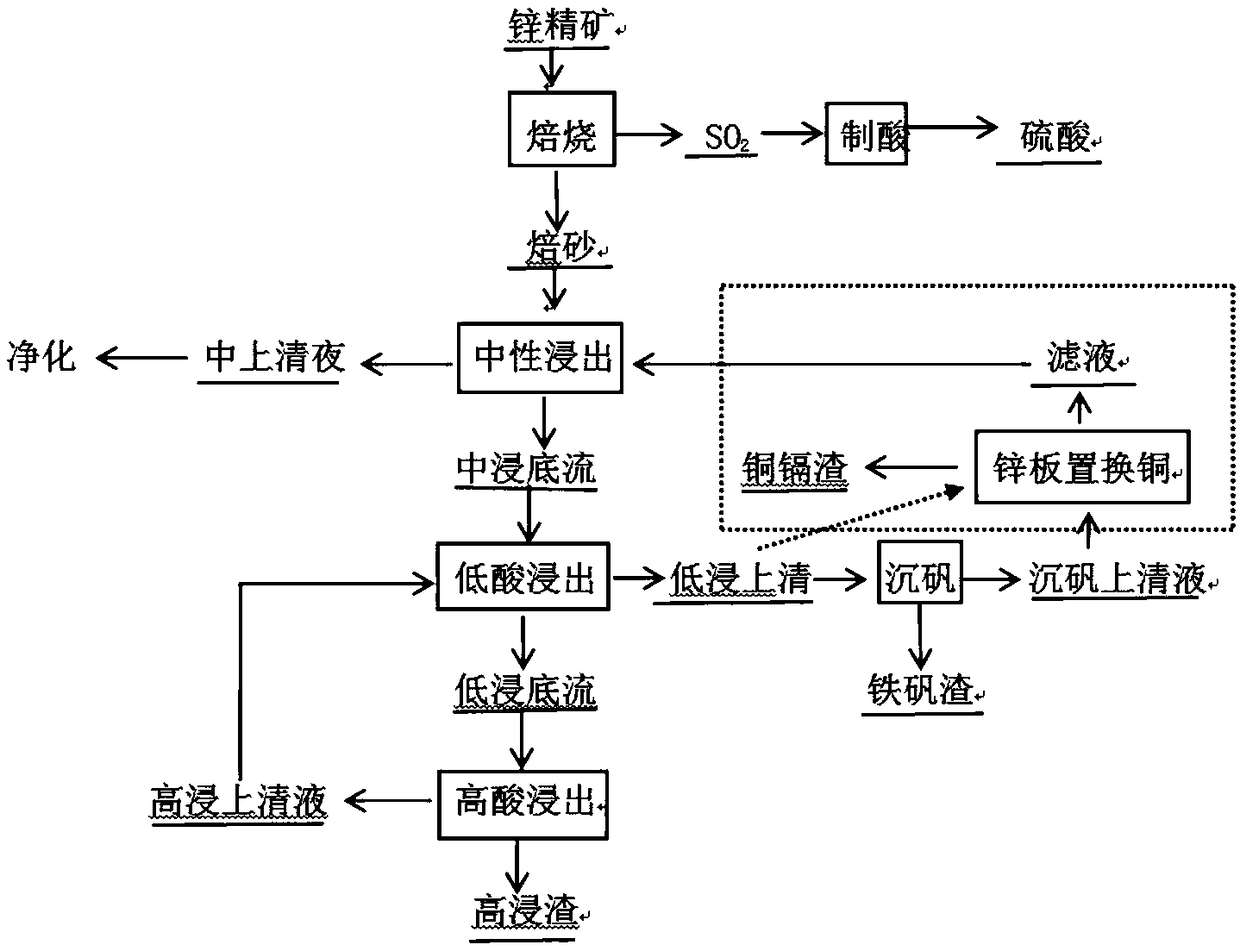

A technology for hydro-smelting zinc and zinc powder is applied in the direction of improving process efficiency, which can solve problems such as unstable supply of auxiliary materials, and achieve the effects of improving utility, improving the utilization rate of effective zinc, and improving the grade of copper and cadmium.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

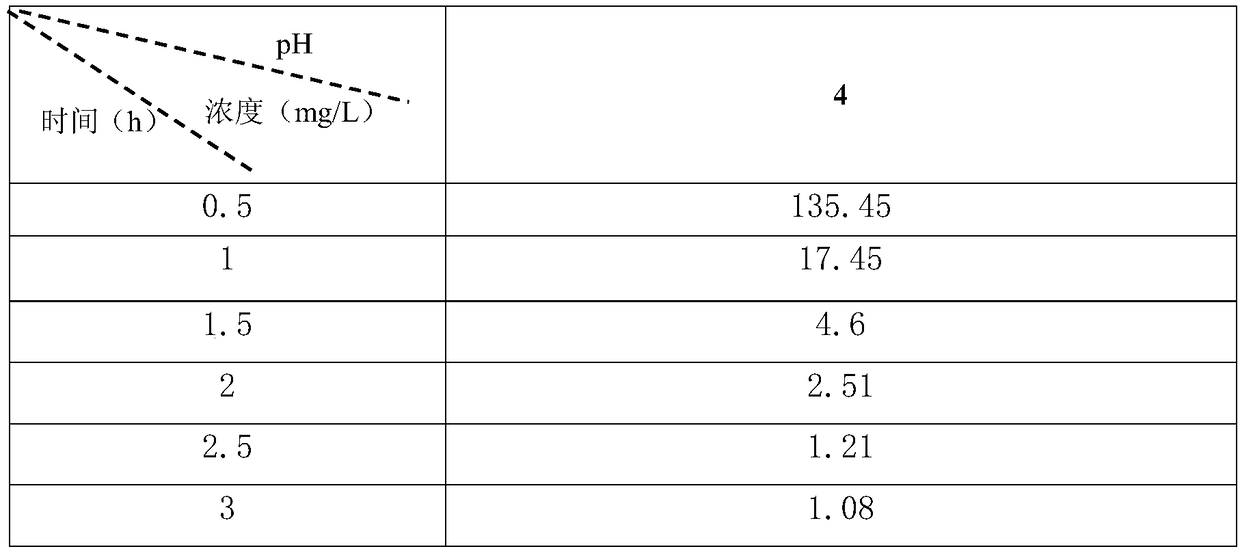

[0019] (1) At a temperature of 80° C., the pH is 4, and the concentration of copper, cadmium and zinc is respectively 1000 mg / L, 200 mg / L and 150 g / L of heavy alum supernatant into the reaction tank.

[0020] (2) Put the "non" shaped stirring paddle equipped with zinc plate into the reaction tank of step (1), stir the reaction time for 0.5 hour, see Table 1 for the change of copper concentration in the solution, and the purification slag contains 10.5% zinc.

[0021] Table 1: Changes in the concentration of copper ions in the supernatant of sinking alum at 80°C under the replacement of zinc flakes

[0022]

Embodiment 2

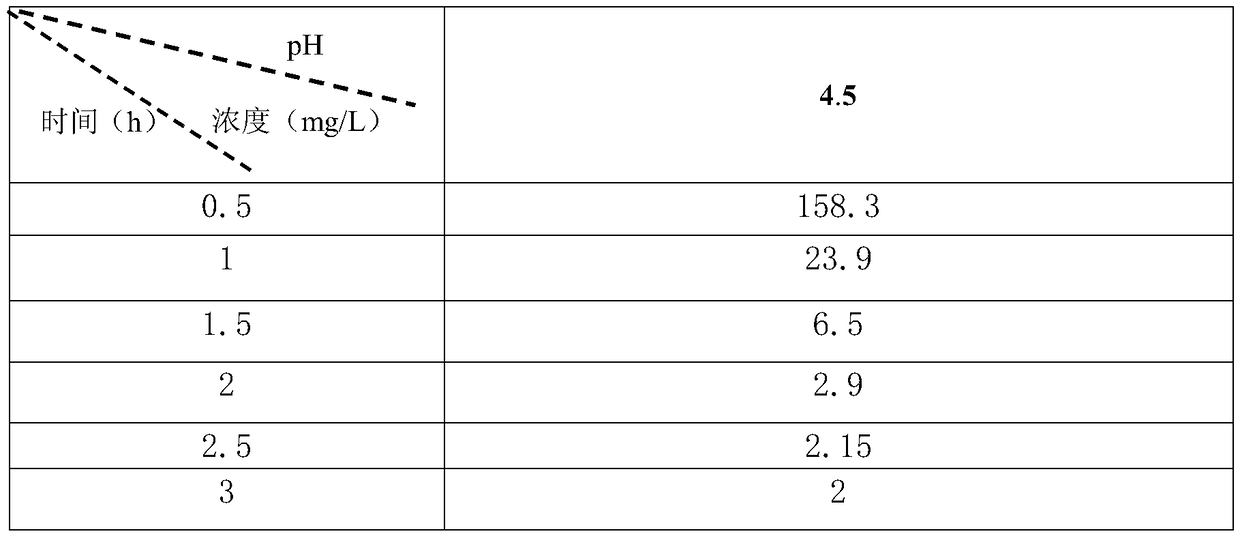

[0024] (1) At a temperature of 70° C., the pH is 4.5, and the concentration of copper, cadmium and zinc is respectively 1000 mg / L, 200 mg / L and 150 g / L.

[0025] (2) Put the "non" shaped stirring paddle equipped with zinc plate into the reaction tank of step (1), stir the reaction time for 0.5 hour, see Table 2 for the change of copper concentration in the solution, and the purification slag contains 9.5% zinc.

[0026] Table 2: Changes in the concentration of copper ions in the supernatant of 70°C low leaching under the replacement of zinc flakes

[0027]

Embodiment 3

[0029] (1) At a temperature of 60° C., the pH is 5, and the concentration of copper, cadmium and zinc is respectively 1000 mg / L, 200 mg / L and 150 g / L of heavy alum supernatant into the reaction tank.

[0030] (2) Put the "non" shaped stirring paddle equipped with zinc plate into the reaction tank of step (1), stir the reaction time for 1 hour, the change of copper concentration in the solution is shown in Table 3, and the purification slag contains 11.2% zinc.

[0031] Table 3: Changes in the concentration of copper ions in the supernatant of sinking alum at 60°C under the replacement of zinc flakes

[0032]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com