Method for quickly and simultaneously measuring moisture diffusion and moisture permeability of biomass material

A biomass material and diffusivity technology, which is used in the analysis of suspensions and porous materials, analysis of materials, and absorption and weighing of materials, etc., can solve the problems of single measurement of moisture permeability or moisture diffusivity, and uncontrollable measurement of ambient temperature, etc. Achieve fast test methods, constant airflow conditions, and short time-consuming effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

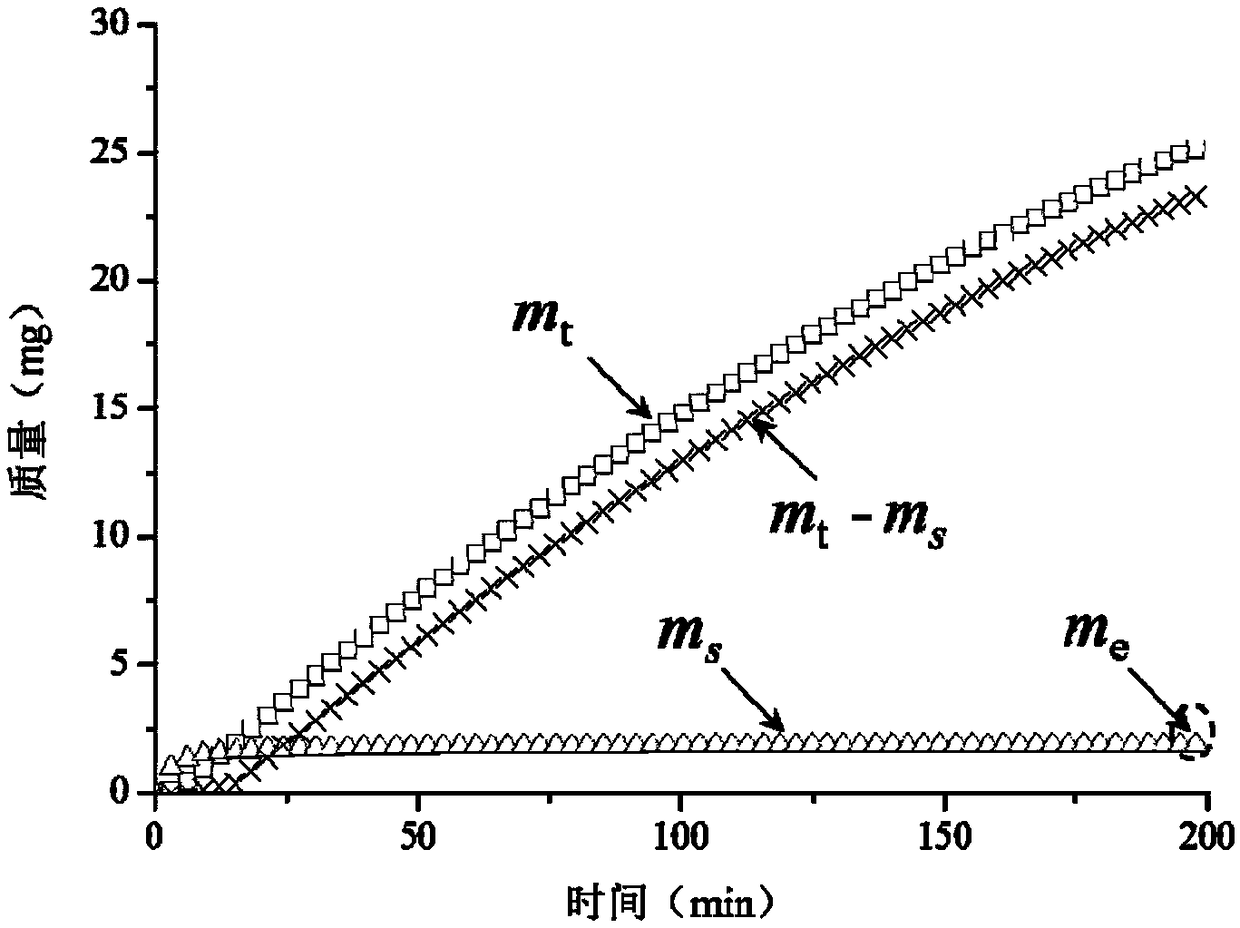

[0031] Embodiment 1: Moisture diffusibility and moisture permeability determination of poplar diameter section when humidity is 30%

[0032] Step 1: Cut out thin slices with a thickness of 50um on the radial section of poplar wood, and trim the section into a circle with a diameter of 1.5cm. Calculate the cross-sectional area A and volume V of the sheet.

[0033] Step 2, place the poplar flakes in step 1 on the tray of the dynamic vapor adsorption instrument, and dry to absolute dryness under the condition of 0% humidity to obtain the absolute dry mass m 0 ; Then, under the constant condition of 30% humidity, record the mass change of the slice in t time, denoted as m s , and the final equilibrium mass m e .

[0034] Step 3, the poplar wood slice in step 2 is placed between the two layers of O-shaped rubber gaskets in the diffusion cell, and 50 mg of phosphorus pentoxide is put into the diffusion cell.

[0035] Step 4, place the diffusion cell in step 3 on the tray of the ...

Embodiment 2

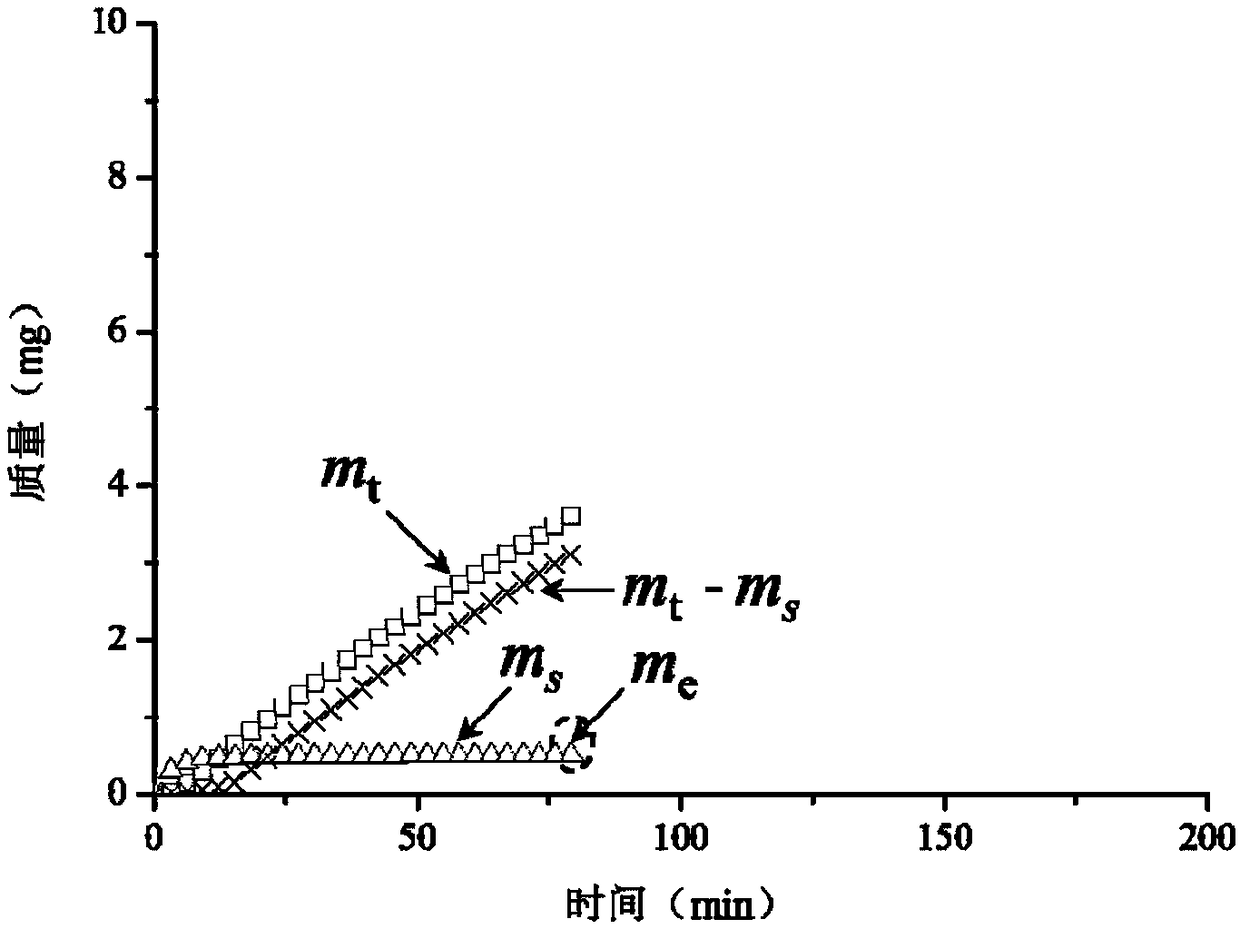

[0037] Embodiment 2: Moisture diffusibility and moisture permeability determination of Chinese fir string cut surface when humidity is 60%

[0038] Step 1: Cut out a thin slice with a thickness of 100um on the cut surface of the fir string, and trim the section into a circle with a diameter of 1.5cm. Calculate the cross-sectional area A and volume V of the sheet.

[0039] Step 2, place the Chinese fir flakes in step 1 on the tray of the dynamic vapor adsorption instrument, dry to absolute dryness under the condition of 0% humidity, and obtain the absolute dry mass m 0 ; Afterwards, under the constant condition of 60% humidity, record the mass change of the sheet within t time, denoted as m s , and the final equilibrium mass m e .

[0040] Step 3, place the Chinese fir slice in step 2 between two layers of O-shaped rubber gaskets in the diffusion cell, and put 100 mg of silica gel into the diffusion cell.

[0041] Step 4, place the diffusion cell in step 3 on the tray of the ...

Embodiment 3

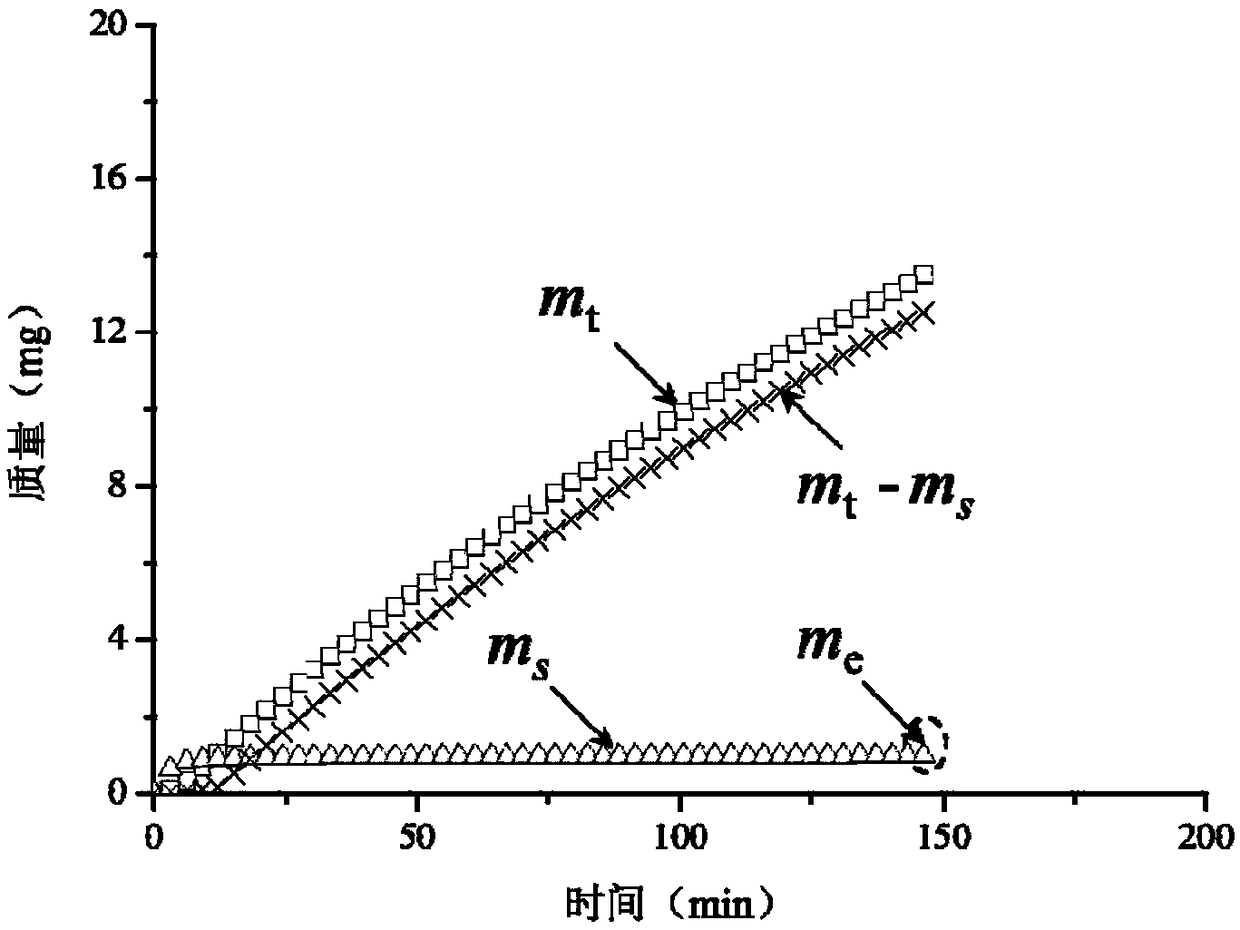

[0043] Embodiment 3: Moisture diffusibility and moisture permeability determination of bamboo cross-section when humidity is 85%

[0044] Step 1: Cut out thin slices with a thickness of 150um on the cross-section of the bamboo, and trim the section into a circle with a diameter of 1.5cm. Calculate the cross-sectional area A and volume V of the sheet.

[0045] Step 2, place the bamboo flakes in step 1 on the tray of the dynamic vapor adsorption instrument, dry to absolute dryness under the condition of 0% humidity, and obtain the absolute dry mass m 0 ; Then, under the constant condition of 85% humidity, record the mass change of the sheet in t time, denoted as m s , and the final equilibrium mass m e .

[0046] In step 3, the bamboo sheet in step 2 is placed between two layers of O-shaped rubber gaskets in the diffusion cell, and 120 mg of calcium chloride is put into the diffusion cell.

[0047] Step 4, place the diffusion cell in step 3 on the tray of the dynamic vapor s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com