Method for softening dried squids through ultrasonic wave assisted immobilized alkali protease

A technology of protease and ultrasound, which is applied in the direction of fixing on/in organic carriers, hydrolytic enzymes, food science, etc., can solve problems such as time-consuming, endangering the health of eaters, and residues of squid chemical reagents, so as to expand the range of eating groups , improved elasticity and chewiness, and shortened softening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

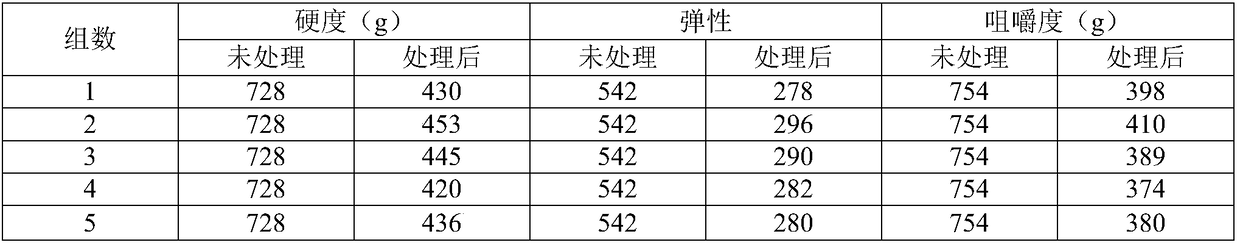

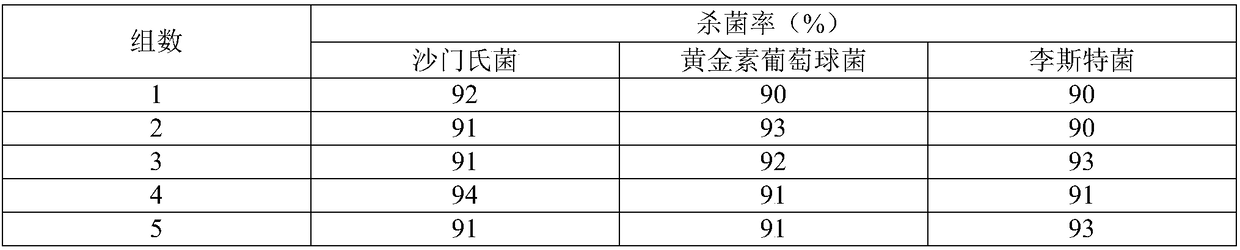

[0026] The dried squid is cut into 3cm wide strips, put into the softening solution containing the alkaline protease immobilized by crab shell biomass activated carbon with an enzyme concentration of 200u / g, under the condition that the ultrasonic intensity is 30KHz and the ultrasonic power is 600W, The ultrasonic temperature was controlled at 40°C, and the ultrasonic treatment was continued for 15 min. Wash the softened squid with clear water, and then ultrasonically treat it in clear water for 2 minutes. Then use a texture analyzer to measure its hardness, elasticity and chewiness, and compare it with the untreated dried squid. Then the microorganisms on the surface of the softened and sterilized squid slices are cultivated to detect the microorganism content.

[0027] Wherein, the preparation method of the alkaline protease immobilized by activated carbon of crab shell biomass is as follows: wash the crab shells, soak them in an acetic acid solution with a mass fraction of...

Embodiment 2

[0029] Cut dried squid into strips with a width of 2.2cm, put them into the softening liquid containing crab shell biomass activated carbon immobilized alkaline protease with an enzyme concentration of 200u / g, under the condition that the ultrasonic intensity is 70KHz and the ultrasonic power is 600W , the ultrasonic temperature was controlled at 40°C, and the ultrasonic treatment was continued for 6 min. Wash the softened squid with clean water, and then ultrasonically treat it in clean water for 1.5 min. Then use a texture analyzer to measure its hardness, elasticity and chewiness, and compare it with the untreated dried squid. Then the microorganisms on the surface of the softened and sterilized squid slices are cultivated to detect the microorganism content.

[0030] Wherein, the preparation method of the alkaline protease immobilized by activated carbon of crab shell biomass is as follows: wash the crab shells, soak them in an acetic acid solution with a mass fraction of...

Embodiment 3

[0032] Cut dried squid into strips with a width of 2.2cm, put them into the softening solution containing crab shell biomass activated carbon immobilized alkaline protease with an enzyme concentration of 300u / g, under the condition that the ultrasonic intensity is 40KHz and the ultrasonic power is 600W , the ultrasonic temperature was controlled at 45°C, and the ultrasonic treatment was continued for 11 minutes. Wash the softened squid with clear water, and then ultrasonically treat it in clear water for 2 minutes. Then use a texture analyzer to measure its hardness, elasticity and chewiness, and compare it with the untreated dried squid. Then the microorganisms on the surface of the softened and sterilized squid slices are cultivated to detect the microorganism content.

[0033] Wherein, the preparation method of the alkaline protease immobilized by activated carbon of crab shell biomass is as follows: wash the crab shells, soak them in an acetic acid solution with a mass fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com