Light solvent recovery device for field of dangerous waste treatment, skid-mounted structure therefor and light solvent recovery method

A recycling device and light solvent technology, which is applied in the field of hazardous waste treatment and hazardous waste treatment, can solve the problems of scattered equipment installation, inconvenient operation, inconvenient disassembly and assembly, etc., and achieves compact arrangement of equipment, flexible and convenient movement, and reduced construction period. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

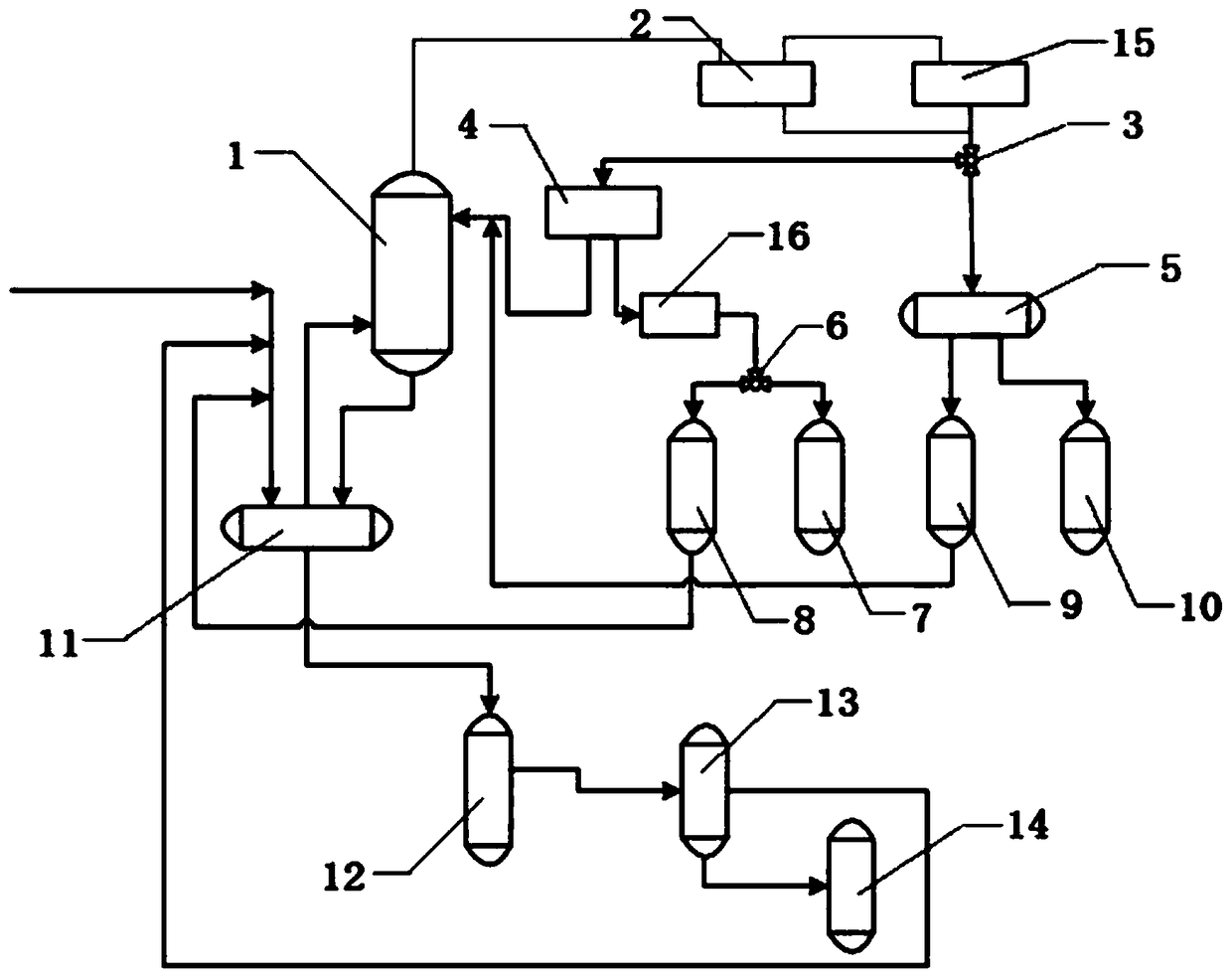

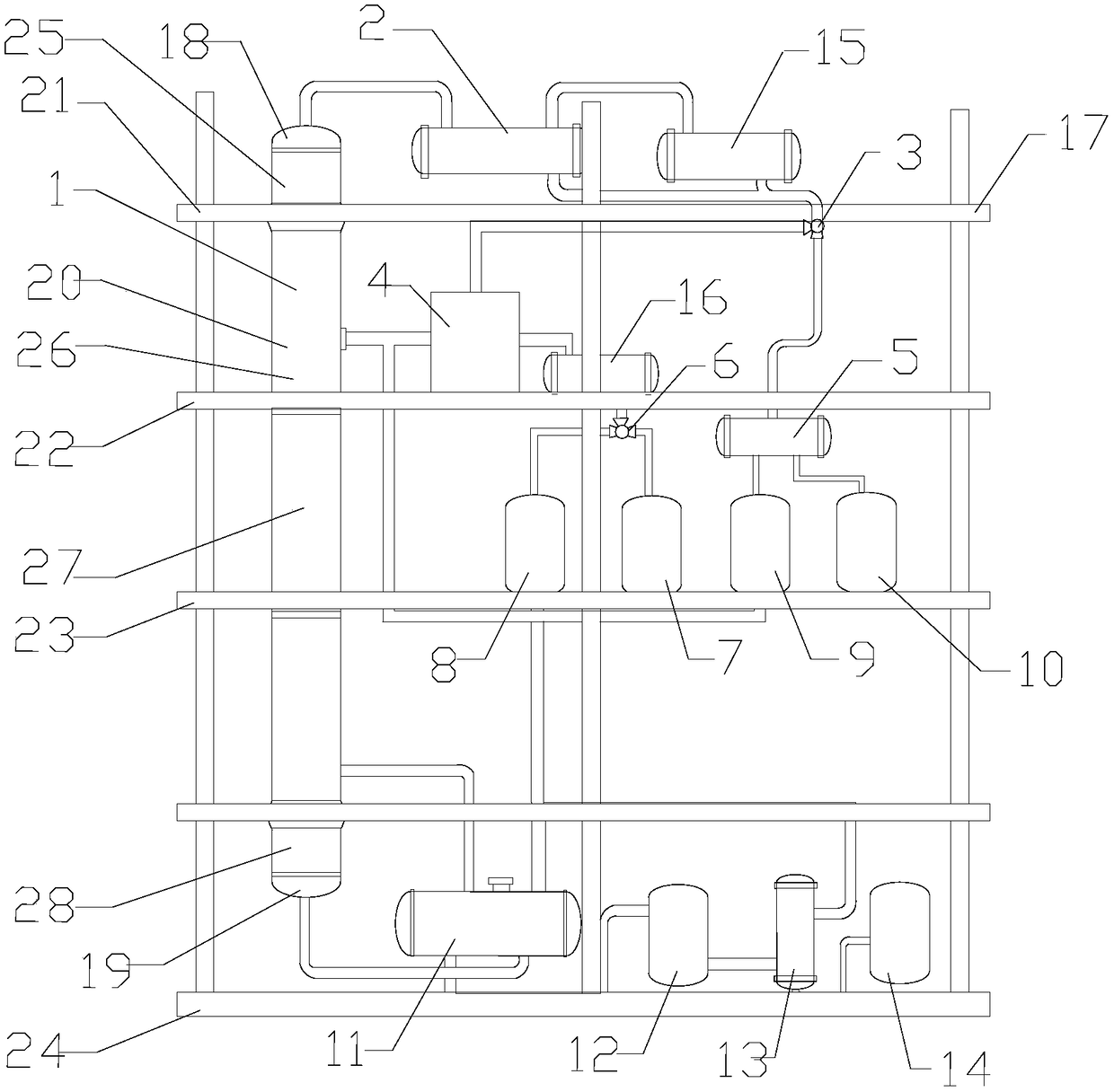

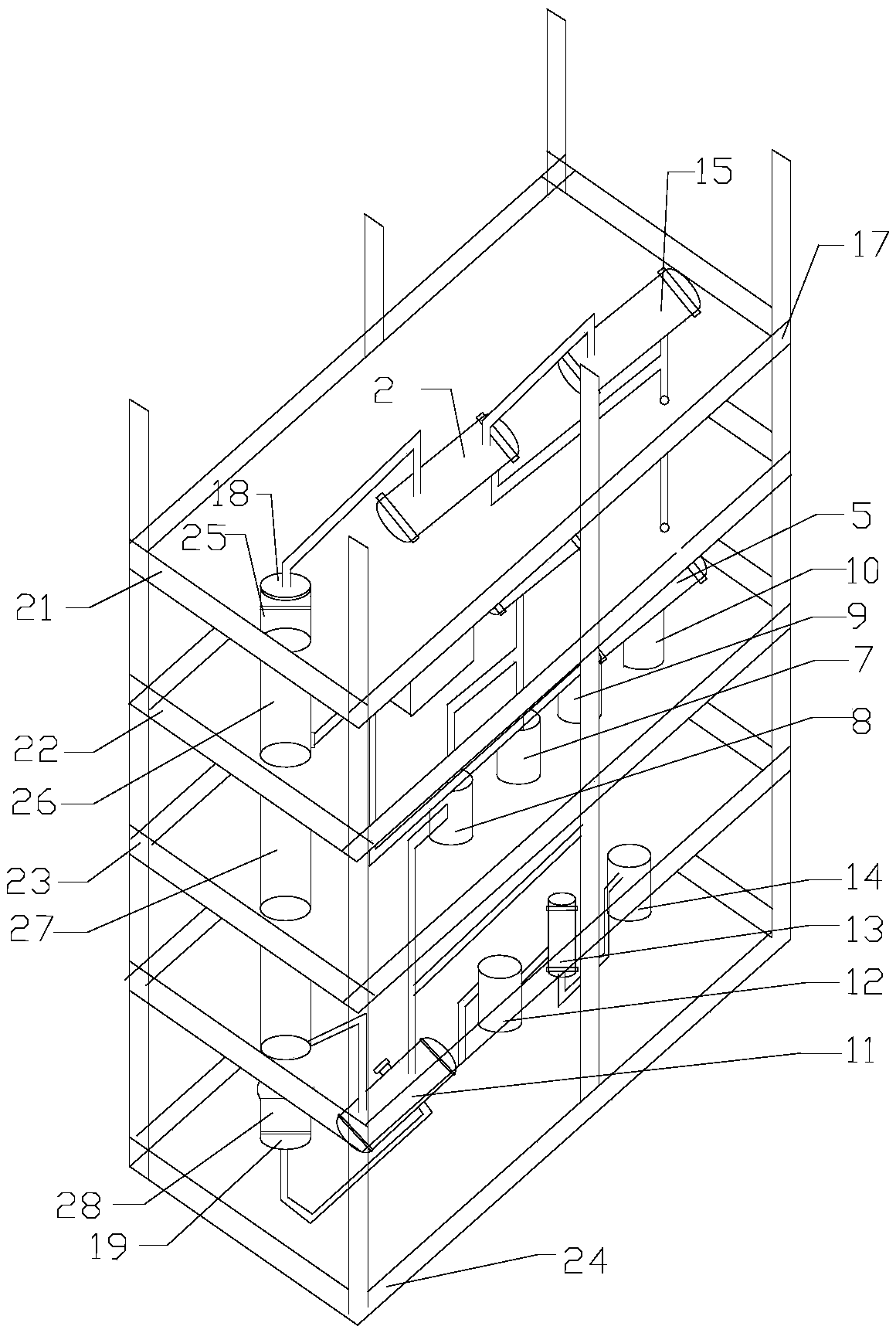

Method used

Image

Examples

Embodiment 1

[0069] The liquid hazardous waste to be treated mainly contains 40% hexane, 1% heavy component and 59% water.

[0070] The first step is to transport the liquid to be treated to the rectification tank. The temperature of the tower tank is gradually raised from 40°C to 120°C. The hazardous waste to be treated is heated and vaporized and then enters the rectification tower for separation. After the total reflux is stable, A substantially constant concentration gradient and temperature gradient are formed in the tower;

[0071] In the second step, the gas produced from the top of the rectification tower is condensed by a condenser and a trap and then sent to a phase separation tank for phase separation. After phase separation in the phase separation tank, the heavy phase water phase is extracted and collected to waste liquid In the collection tank, the light-phase hexane enters the reflux tank, and is completely refluxed into the tower through the reflux pump, and the liquid phas...

Embodiment 2

[0074] The liquid hazardous waste to be treated mainly contains 55% of dichloromethane, 1% of heavy components, and 44% of water.

[0075] The first step is to transport the liquid to be treated to the rectification tank. The temperature of the tower tank is gradually raised from 40°C to 120°C. The hazardous waste to be treated is heated and vaporized and then enters the rectification tower for separation. After the total reflux is stable, A substantially constant concentration gradient and temperature gradient are formed in the tower;

[0076] In the second step, the gas produced from the top of the rectification tower is condensed by a condenser and a trap and then sent to a phase separation tank for phase separation. After phase separation in the phase separation tank, the heavy phase water phase is extracted and collected to waste liquid In the collection tank, the light phase dichloromethane enters the reflux tank, and is completely refluxed into the tower through the ref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com