Preparation method and application of nano zero-valent iron composite material

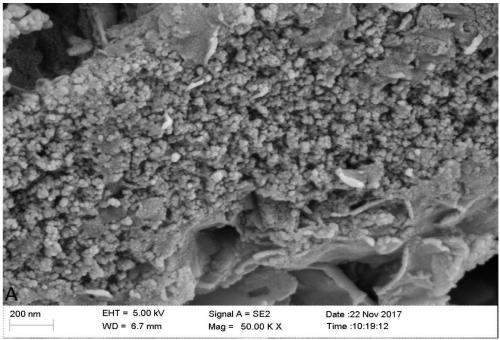

A technology of nano-zero-valent iron and composite materials, which is applied in chemical instruments and methods, water/sludge/sewage treatment, water pollutants, etc., can solve problems affecting the adsorption efficiency of nano-zero-valent iron particles, and achieve improved capacity, Good dispersibility and uniform particle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The invention provides a preparation method of a nanometer zero-valent iron composite material, comprising: S1) in a protective atmosphere, mixing a carrier with an iron salt solution to obtain a carrier iron salt suspension; S2) in a protective atmosphere, mixing the After the carrier iron salt suspension is mixed and reacted with the sunflower leaf extract, the nanometer zero-valent iron composite material is obtained.

[0039] Wherein, the present invention has no special limitation on the sources of all raw materials, which can be commercially available or self-made.

[0040] The carrier can be an inorganic carrier well known to those skilled in the art, and there is no special limitation. In the present invention, it is preferably one or more of bentonite, activated carbon, expanded graphite and calcium carbonate, more preferably bentonite. The use of bentonite as a carrier is based on the fact that natural bentonite materials are rich in reserves, easy to obtain, ...

Embodiment 1

[0050] 1.1 Preparation of sunflower leaf extract

[0051] Weigh 200 g of fresh sunflower leaves and add 1000 mL of deionized water, heat in a water bath at 80° C. for 2 h, cool to room temperature and vacuum filter to obtain sunflower leaf extract.

[0052] 1.2 Preparation of iron salt solution

[0053] An appropriate amount of ferrous sulfate was dissolved in a mixture of absolute ethanol and deionized water with a volume ratio of 7:3 to prepare an iron salt solution with a concentration of 0.05 mol / L.

[0054] 1.3 Preparation of bentonite iron salt suspension

[0055] Add an appropriate amount of bentonite to the above-mentioned iron salt solution, wherein the mass ratio of bentonite to iron element in the iron salt solution is 2:1, and fully stir with an electric stirrer at a speed of 800r / min for 6 hours to prepare a bentonite iron salt suspension.

[0056] 1.4 Preparation of sunflower leaf green synthetic nano-zero valent iron composite material suspension

[0057] Add...

Embodiment 2

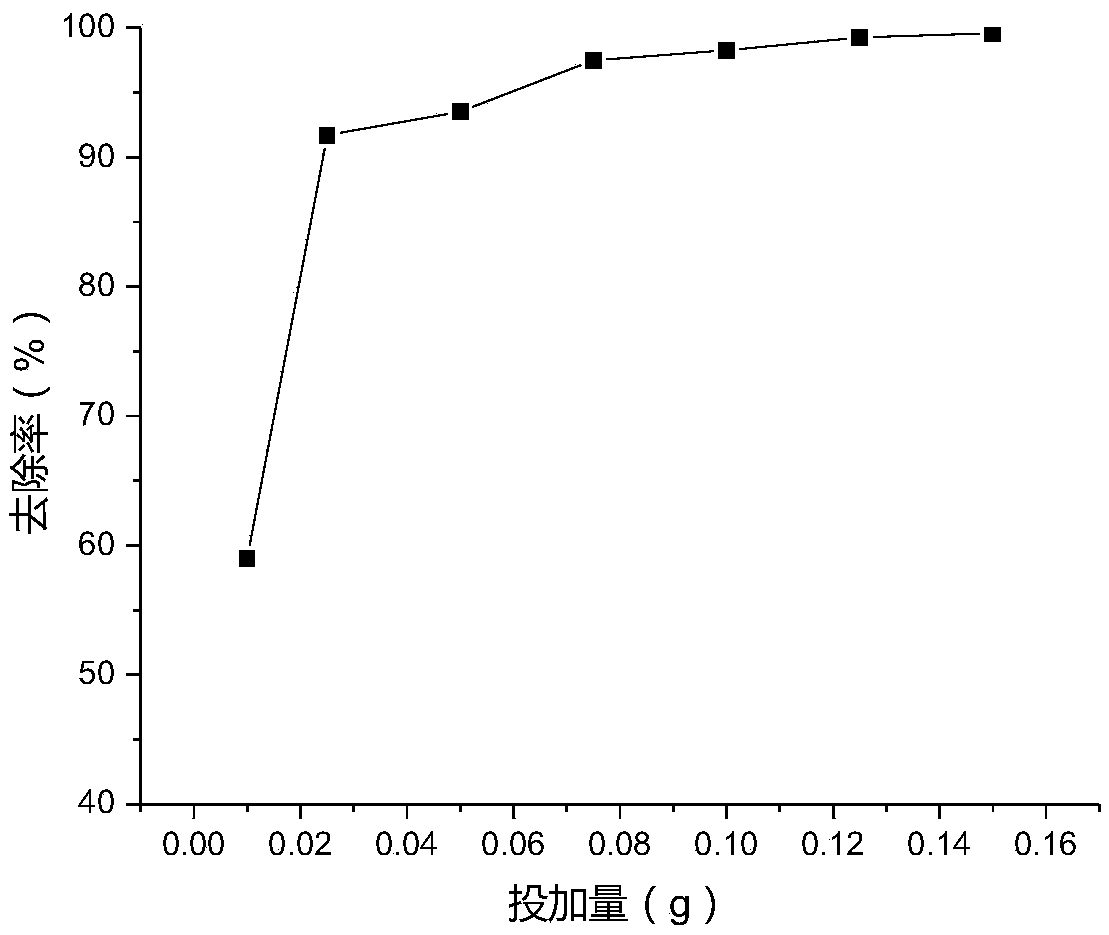

[0063] The nano-zero-valent iron composite material prepared in Example 1 was used for the removal of U(VI) in water.

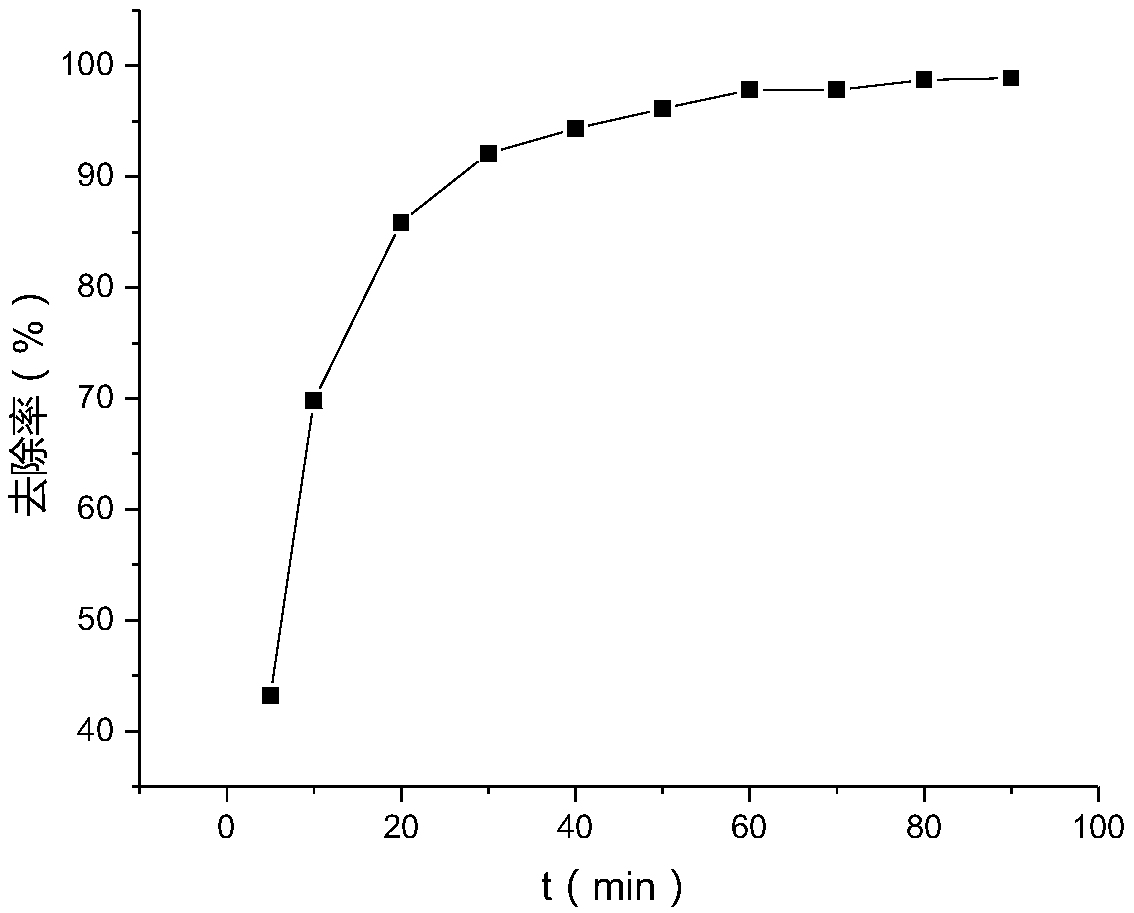

[0064] Take 20mL of 9 parts of uranium-containing wastewater with a concentration of 10mg / L, adjust the pH to 5, add 0.1g of the composite material prepared in Example 1, and place them in a constant temperature shaking box at 30°C to react 10, 20, 30, 40, 50, 60, 70, 80, 90min, take samples after filtration. The concentration of residual uranium was measured by 5-Br-Padap spectrophotometry, and the results were as follows figure 2 shown.

[0065] The results showed that the removal efficiency increased rapidly in the first 20 minutes of the reaction, and the reaction rate was fast. After 70 minutes, it basically reached equilibrium, and the removal efficiency reached 98.73%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com