Preparation method of n-propyl propionate

A technology of n-propyl propionate and propionic acid, which is applied in the field of preparation of n-propyl propionate, can solve the problems of low catalytic effect of the catalyst, unsatisfactory products, difficult handling of by-products, etc., so as to prevent overheating and improve product quality. Stable, easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

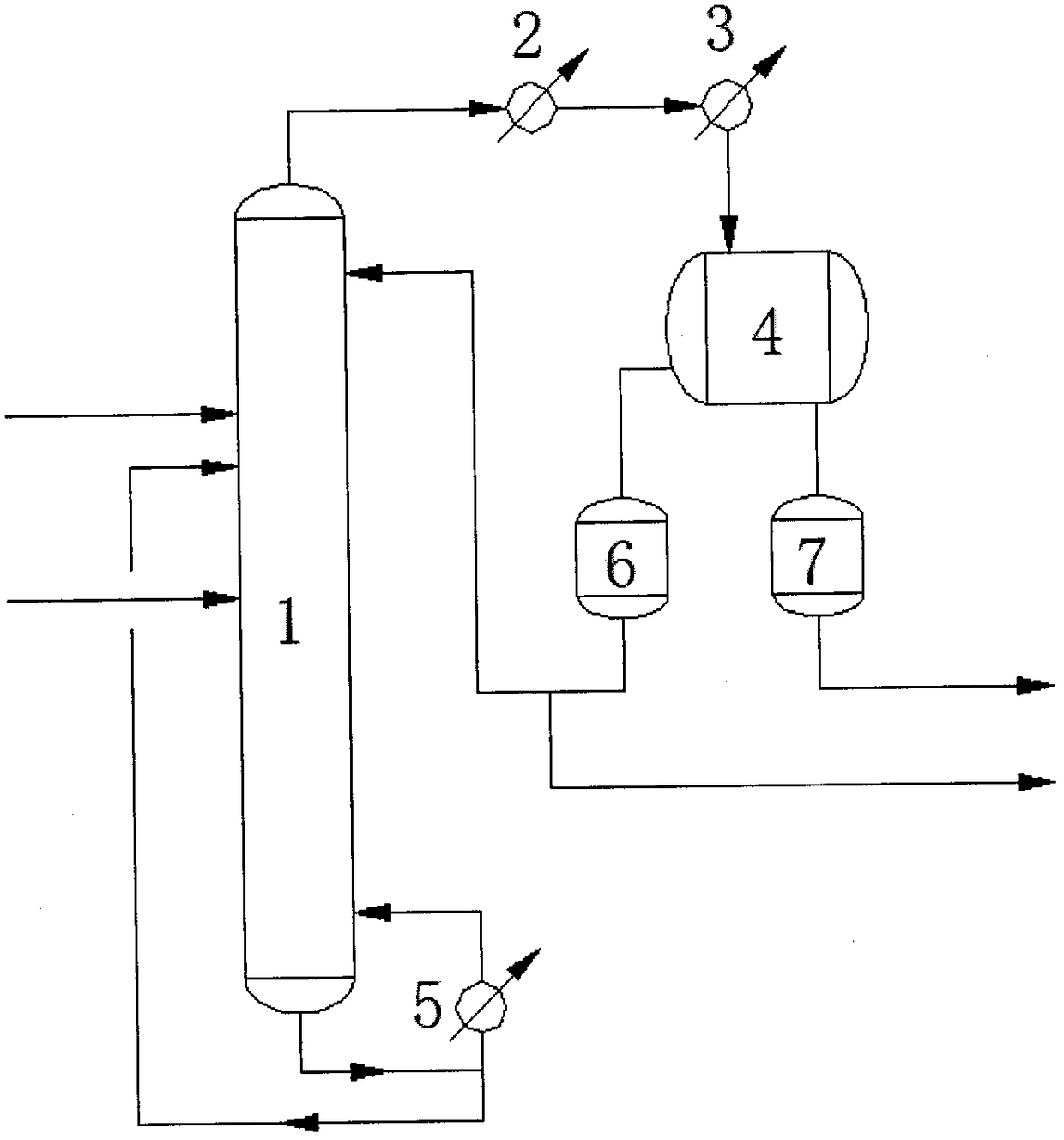

[0028] A preparation method for n-propyl propionate, comprising the following steps:

[0029] Add excess propionic acid and n-propanol to the reactive distillation tower equipped with a catalyst, under the action of the catalyst, an esterification reaction occurs to generate n-propyl propionate, the by-product is water, and the top of the reactive distillation tower contains propionic acid Mixture of n-propyl ester and water;

[0030] The mixture containing n-propyl propionate and water is sent to the phase separator after being condensed, the water phase is extracted, the mass fraction is 0.98-0.998, part of the oil phase is refluxed, and a part is extracted to obtain n-propyl propionate product, The mass score is greater than 0.999;

[0031] Excess propionic acid is extracted from the reactor of the reactive distillation tower, the mass fraction of propionic acid is 0.92-0.94, and returned to the feedstock inlet of propionic acid of the reactive distillation tower to contin...

Embodiment

[0043] 10,000 tons / year of n-propyl propionate production, in which the raw material composition and related parameters are as follows:

[0044] Raw material propionic acid: mass fraction is 0.999, feed rate is 888Kg / h; raw material n-propanol: mass fraction is 0.999, feed rate is 600Kg / h.

[0045] The pressure at the top of the reactive distillation column is 30KPa, the temperature at the top of the column is 81.4°C, the mass ratio of reflux to propionic acid feed is 6.78, and the mass ratio of reflux to n-propyl propionate output is 5.25.

[0046] Obtain n-propyl propionate and water mixture at the top of the reactive distillation tower, through the phase separator phase separation, obtain the n-propyl propionate that mass fraction is 0.99965, and the by-product water that mass fraction is 0.9983; Propionic acid with a mass fraction of 0.9275 is extracted from the tower reactor and returned to the feed inlet of propionic acid to continue to react with n-propanol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com